4

SINGLE & DOUBLE GIRDER TOP-RUNNING BRIDGES

WITH INDIVIDUAL MOTOR DRIVEN

END TRUCKS

P/N: 11532620 REV. AA September 2018

panel, bridge panel to cross conductors, bridge panel to bridge.

motor) in accordance with the appropriate crane interconnection

wiring diagram as shown in Figure 10. If bridge motors quick

connection plugs are not pre-wired, connect leads on motor cables

from the bridge control panel per Figure 1.

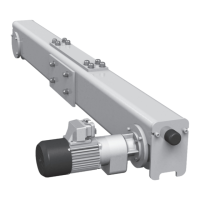

Figure 1. Bridge Gear Motor Quick Connection Plug

CAUTION

Gearmotors provided with this crane kit are intended for

variable frequency control only. The brake used on the

gearmotor is a holding brake with no provision for torque

adjustment. Severe load swing will result without the

controlled deceleration when stopping provided by the

variable frequency control. The use of contactor, across the

line starting, controls is not permitted, will result in damage

and premature failure of these units and void any warranty.

NOTICE

Prior to placing the crane into service, the crane shall

receive an initial inspection. This inspection should be

performed by a qualied person in accordance with

ANSI/ASME B30.2 or B30.17, local, state and provincial

standards and regulations.

START-UP AND PRE-OPERATIONAL INSPECTION

After the crane has been installed on the runway and the crane,

hoist and trolley has been connected to electrical service but prior to

placing into service, as a minimum the following inspections should

be made by a qualied person.

1. Check the main collector system for proper adjustment to

maintain proper contact with conductors. Check along runway

for possible interference if power is supplied by a cable reel or

festooned cable.

WARNING

Lock main runway disconnect switch in open position

before attempting to adjust main collectors or conductors.

2. Check the cross and pushbutton festoon conductors for

adjustment, including cable loop depth, and tracking.

3. Check oil level in both drive gearcases and axle bearing grease

ttings (if provided) for proper lubrication. If lubrication is required

refer to the LUBRICATION SECTION of this manual.

4. Inspect crane to make certain that all bolted connections

and attachments are properly tightened and that all electrical

connections are secure.

5. Inspect and adjust the motor brake air gap. Refer to the

MAINTENANCE SECTION of this manual.

6. The hoist/trolley should be inspected as instructed in the hoist/

trolley manufacturers instruction manual. For a single girder crane

inspect the clearance between the trolley wheels and toe of ange

on bridge girder beam per manufacturers requirements. For a double

girder crane inspect the clearance between wheel anges and the

girder rail per manufacturers requirements. If hoist is equipped with

adjustable limit switches, conrm settings meet the applications

requirements.

7. Inspect the alignment of the trolley end stops to the trolley and the

runway end stops to the bridge endtrucks.

8. Turn power on at both disconnects and mainline. Inspect hoist

for reverse phase condition by ensuring push button operation

corresponds to intended direction of travel and correct if necessary

per manufacturer’s instructions.

9. Operate the crane to verify both motors operate in the same

direction, in both bridge directions.

10. With no load operate hoist/trolley back and forth the full length

of bridge girder and operate the crane the full length of the runway.

During the operation ensure and verify proper clearances from

obstructions per CMAA, ASME B30.2, ASME B30.17 and OSHA

requirements.

11. Load testing the crane should be performed in accordance with

ANSI/ASME B30.2 or B30.17, local, state and/or provincial codes

and regulations. A written report should be prepared during the

performance of this test and placed on le.

OPERATION

OPERATOR QUALIFICATIONS

Safe and efcient crane operation requires skill, extreme care, good

judgment, alertness, concentration and knowledge of and rigid

adherence to proven safety rules and practices. No person should

be permitted to operate a crane or hoist:

1. who does not possess the above characteristics.

2. who is not qualied or has handicaps that could adversely affect

such operation.

3. who has not been properly instructed.

4. who has not been informed and does not have a thorough

knowledge of all applicable safe operating practices, including those

in this book as well as of rigging equipment and practices.

NOTICE

See applicable National, State and Local Safety Codes

and regulations for additional requirements relating to Safe

Operating Practices, including ANSI B30.2 or ANSI B30.17

- latest edition

OPERATING RULES

Operating rules listed below are an earnest effort to encourage

SAFETY and are not intended to take precedence over individual

plant safety rules and regulations or rules set forth by various

applicable codes.

A good operator operates his crane as smoothly as possible and

knows and follows the suggested rules below for safe, efcient

crane handling.

INSTALLATION CONTINUED

CMK_12322 Yale Rotating Axle End Truck Parts 11532619-REV AD_mec.indd 4 10/16/18 2:07 PM

Loading...

Loading...