3

3. How to Operate the Machine

CAUTION

- Do not operate the gun lever with the discharge port facing to another person during machine

operation. A direct hit against the human body may result in an accident such as skin damage.

- Regarding a secondary accident such as hose damage that may be caused without shutting off of the

air supplied to the hose or installation contamination due to a leak from the valve or gun after

completion of the work or at night, the responsibility rests with the user side.

- When the pump causes a malfunction or operation stop, do not disassemble the pump thoughtlessly

and disassemble only necessary portions referring to the item pertaining to <Troubleshooting and

Corrective Measures> on page 4 and judging the situation properly.

<Note>

The electric grease pump runs continuously even if the grease gun closed. When internal pressure goes up to

28 MPa, the grease is relieved by relief valve automatically. Thus this unit is overload free. The grease returns

to pail through the outer tube.

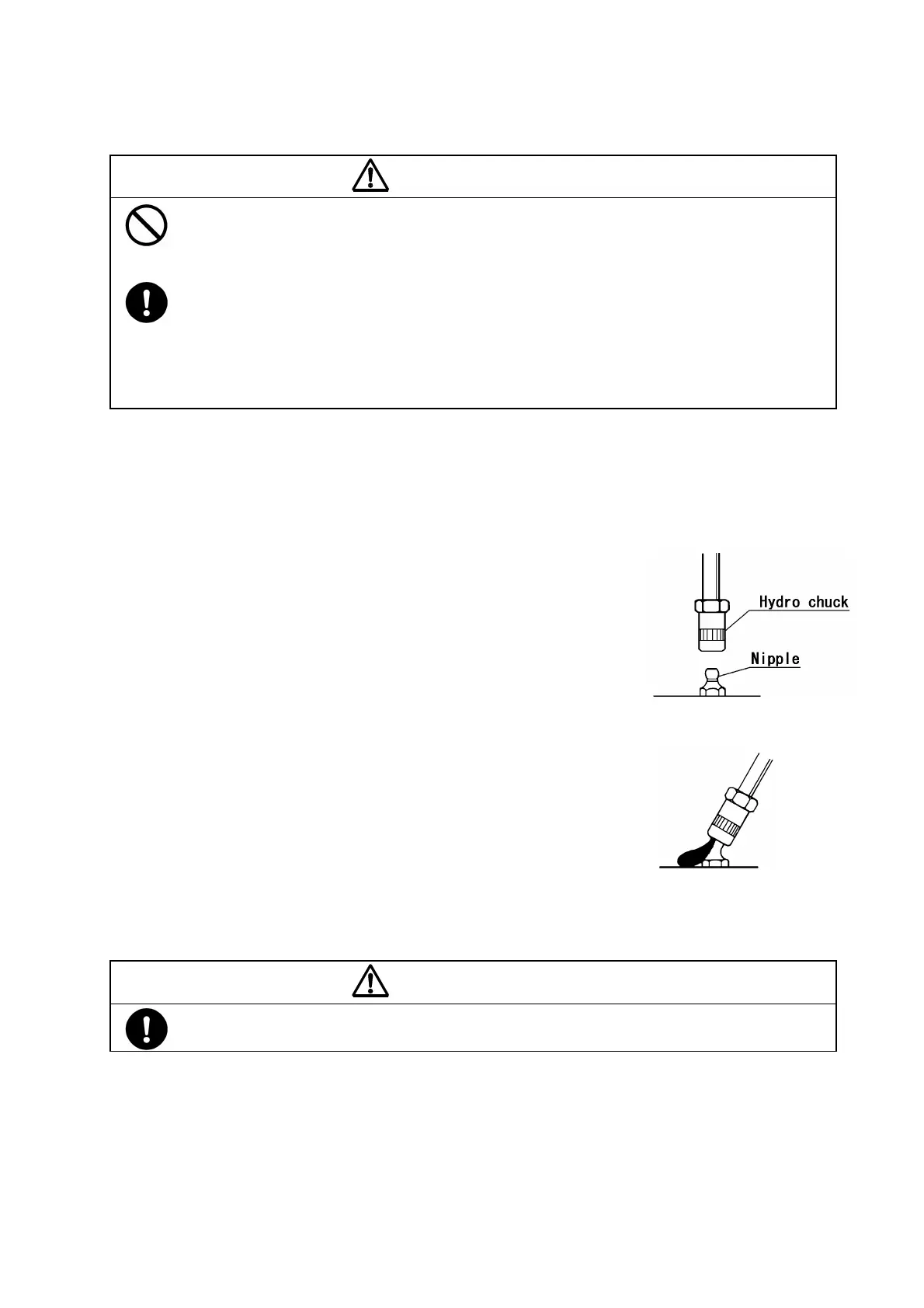

1) Wipe the grease nipple to be used for greasing completely. After that,

push the hydro chuck of the high-pressure grease gun against the nipple

to perform chucking as vertically as possible. (Fig. 4)

2) Pull the lever of the high-pressure grease gun to supply grease. The

pump is automatically operated to supply grease. When grease is

normally injected, old grease will be squeezed out from the groove or

clearance bear the nipple.

3) After completion of grease supply, release the gun lever. The grease

supply will be stopped and the pump will also be stopped automatically.

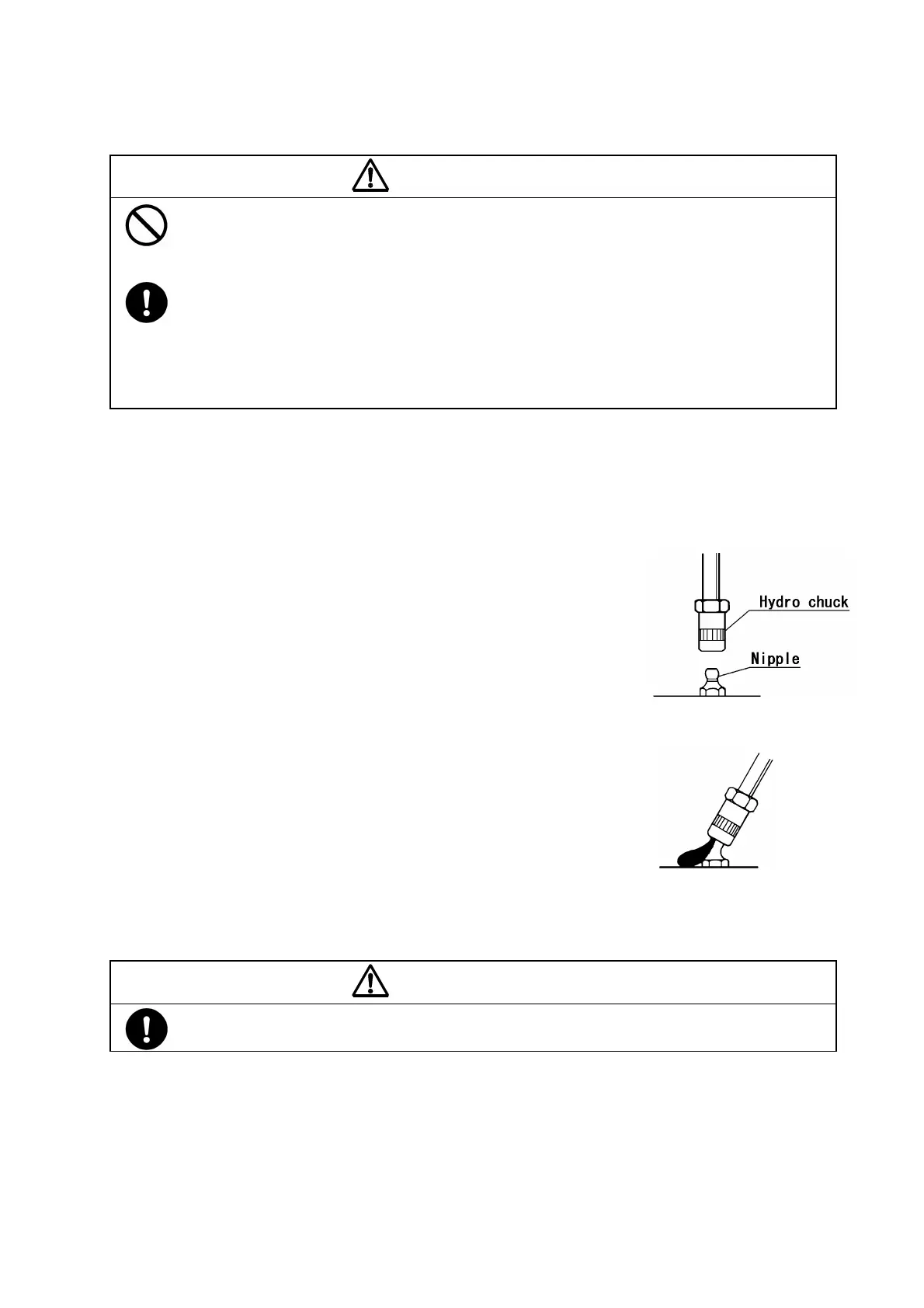

4) Remove the hydro chuck of the grease gun. Since pressure is applied to

the hydro chuck, the head of the nipple may be broken if it is suddenly

pulled. Incline the hydro chuck to bleed the internal pressure and loosen

the claw bite, and the chuck can be easily removed. (Fig. 5)

5) After completion of greasing work or when the pump is not used for a long

time, be sure to shut off the supply air and bleed the internal air of the

pump, grease gun, and hose by operating the gun lever.

6) If the pump is suddenly started, it may be due to non-existence of grease

in the grease can or a cavity produced. Stop the greasing work and make

a check. If the grease is used up, replace the grease can.

[Replacing the grease can]

CAUTION

- When replacing the grease can, be sure to shut off the supply air for safety and pull the gun lever to

bleed the internal pressure of the pump and hose beforehand.

7) Unscrew the 3 wing bolts of the lid, and remove the pump unit from used the grease can and take out the follower

plate.

8) Remove the lid of a new grease can and place the follower plate on the grease horizontally and push the follower

plate by rubbing it until grease comes out from the central hole.

9) Insert the pump in the packing in the middle of the follower plate and set the lid on the pail can. Screw the 3 wing

bolts equally so fix the lid securely.

Fig. 5

Fig. 4

Loading...

Loading...