4

4. Maintenance and Inspection

4.1 Troubleshooting and Corrective Measures

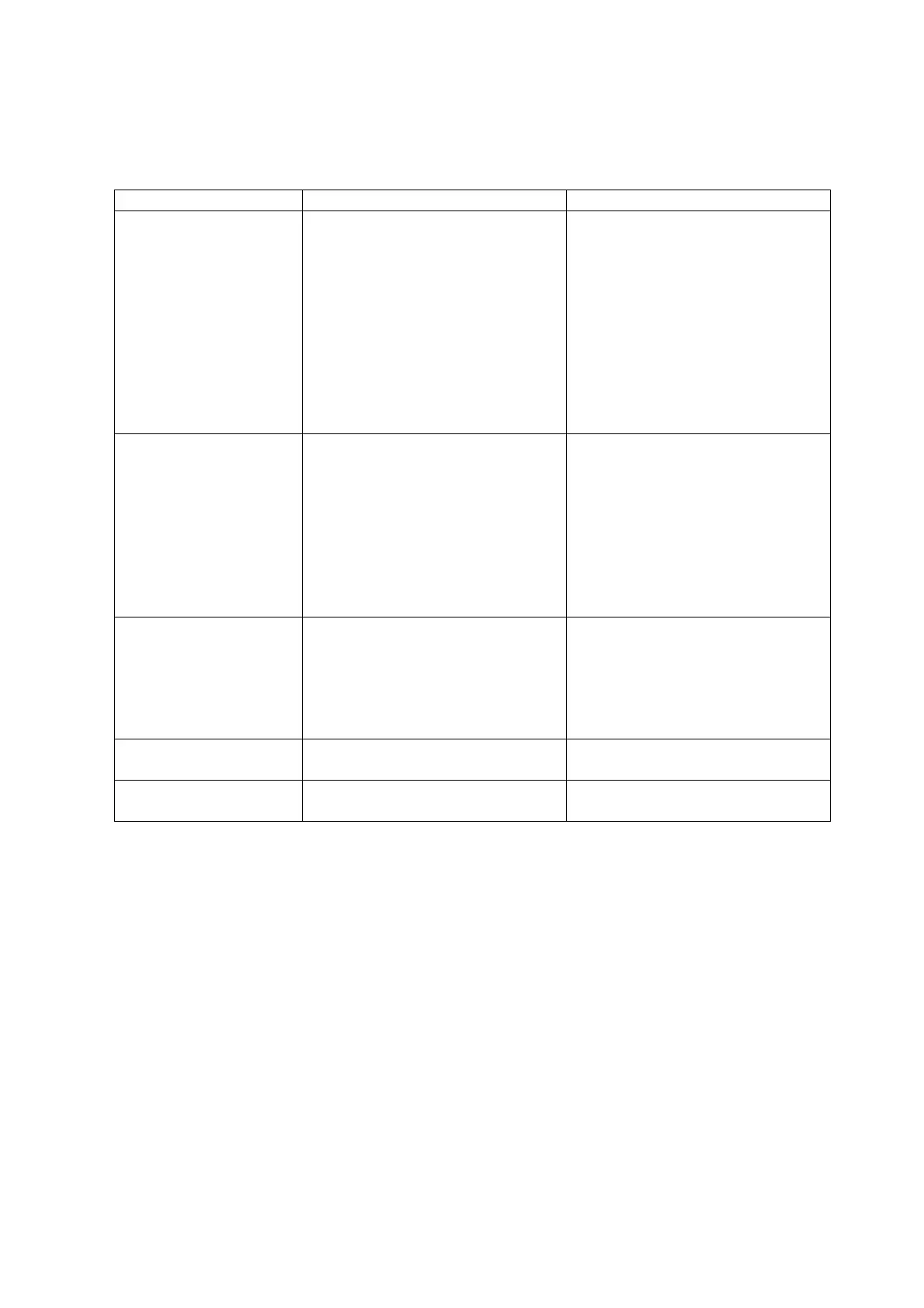

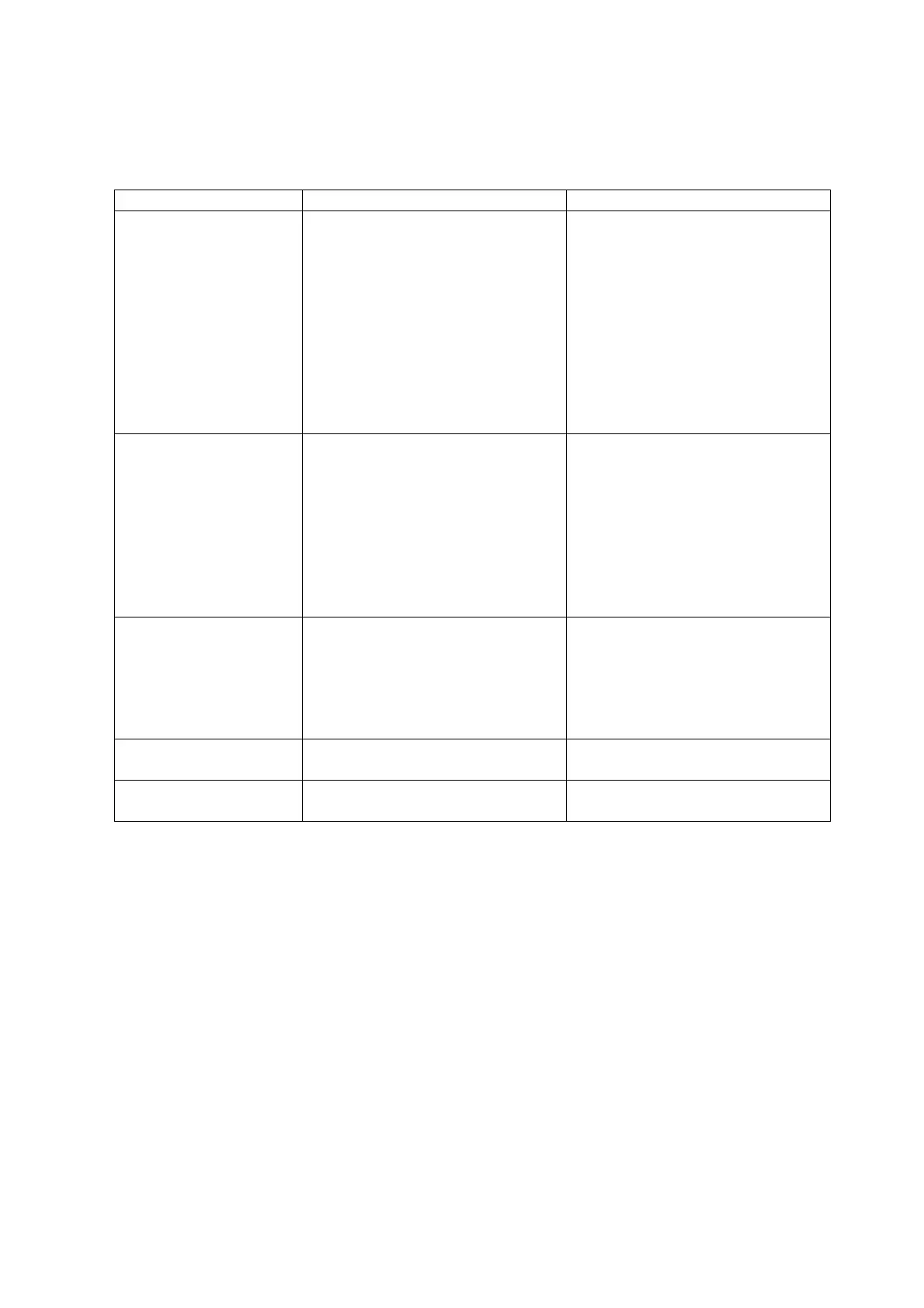

Symptom Contents of inspection Corrective measure

♦ The pump fails to start. - Check if the power cable is cut.

- Check if the fuse is blown.

- Uninstall the lower pump and operate

only by the motor.

↓

(Separate the lower pump and operate

the pump with only the motor.)

→ If the pump is operated, the lower

pump is defective.

→ If the pump is not operated, the

motor is defective.

- Change to the new cable.

- Change to new fuse (7A).

- Repair service for the lower pump.

- Repair service.

♦ The pump is operated

but does not feed the

material by pressure.

- Check if the delivery hose and grease

gun is clogged up.

- Check if the grease is ran out.

- Check if the grease does not touch to

the pump suction because of cavity or

diagonal installation of the follower

plate.

- Uninstall the lower pump and operate

only by the motor.

- Remove the cause of clogging.

- Replace to the new pail.

- Install the follower plate horizontally

and push down till the grease comes

out from the packing. Then operate

the pump again.

- Check the lower pump.

♦ The pump is operated

but the pressure and

flow rate are insufficient.

- Check if leakage is found on the

connection of valve kit, hose and gun.

- Check if the relief valve is loosens.

- Check if the valve seat at lower pump

is worn out.

- Tighten the connections

- Adjust the relief valve at proper

position.

- Change to new valve seat.

♦ Grease leaks from the

motor.

- Check if the seal packing between

motor and material pump is worn out.

- Change to new seal packing.

♦ The pump makes noise. - Check if foot valve is stuck by foreign

substance.

- Remove the foreign substance.

4.2 Maintenance and Inspection

The hose is a consumable part. Check it periodically. If any blemish or leakage is found, replace the hose little

earlier. The packing and slide portion parts of the pump are worn away. Check and replace them once a year.

Loading...

Loading...