2-14

Outboard Rigging Guide - 2001 Jet Drive Eng. Mtg., Maintenance,

Shift Cable Instruction, Service Info.

3. Make two diagonal braces from 1/2" electri-

cal conduit. Flatten each end in a vise, and

drill 1/4" holes in them. Determine the posi-

tion and angle of the forward bend. Attach

them to the boat in a solid location, such as to

the seats or gunwales. Avoid attachment to

flexible aluminum panels.

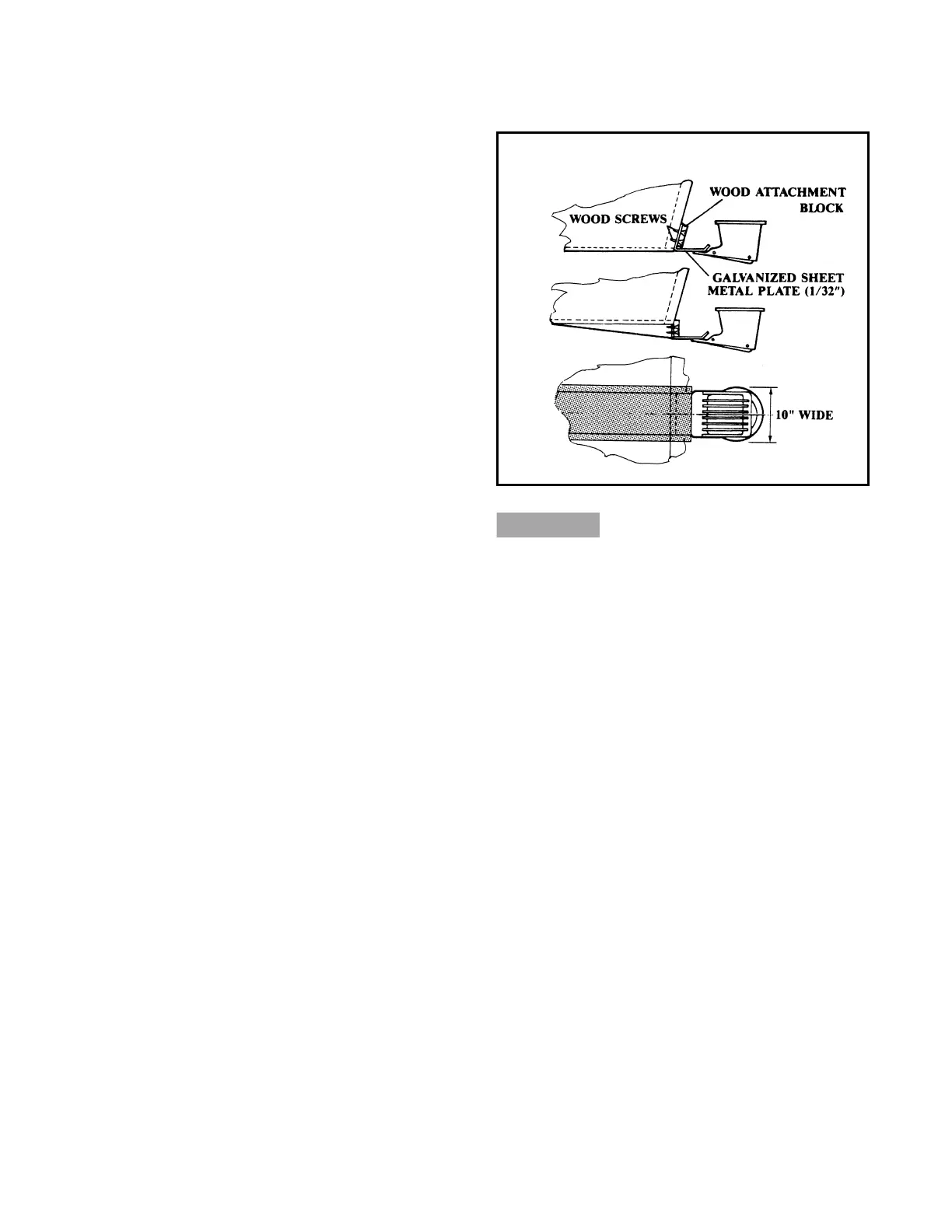

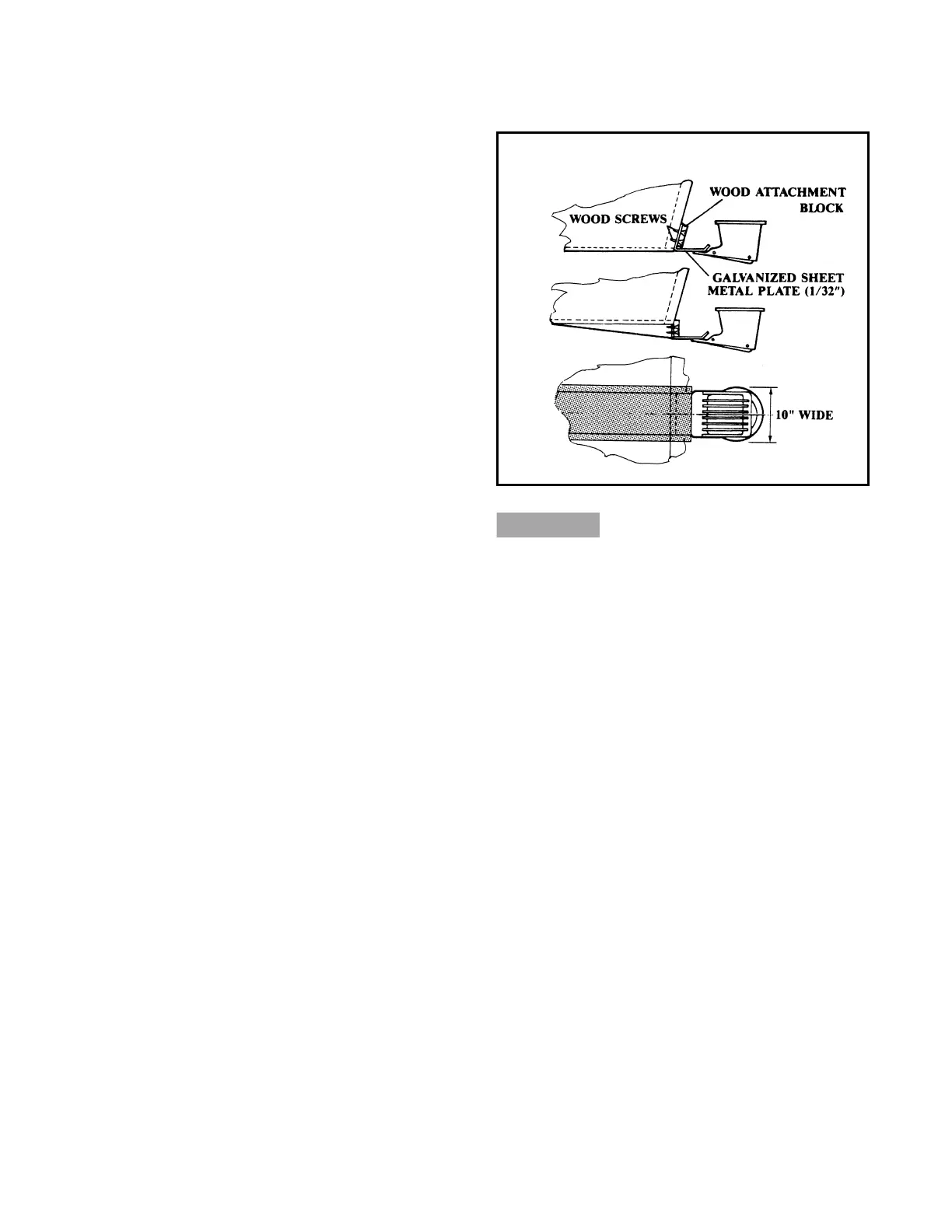

Anti-Cavitation Plates

To reduce spray or to further reduce cavitation in

rough water, a 1/32" - thick metal plate can be

installed to block the entrance of air into the water

in front of the jet drive intake scoop. Installation

of this plate will also allow a slightly higher motor

mounting point, which, of course, will reduce

drag.

The position for proper mounting is shown in the

first part of the accompanying illustration.

An alternate mounting position for the plate (with

the plate attached to a keel or wedge for use in

“white water”) is shown in the second and third

parts of the illustration. The third part shows the

width of the plate, as well as the width of the

drop-bottom wedge that positions the intake in

more solid water. This installation, however,

reduces shallow-water capabilities and should be

used only when necessary.

After any of these procedures are undertaken,

the motor height and tilt settings should be

checked and reset (as necessary) to avoid

excessive cavitation that could lead to impeller

damage.

NOTE: Either of the above modifications should

utilize only marine-grade woods; silicon-base,

waterproofing sealing compounds (between com-

ponents and around screws); and marine-grade

paints. Remember, once you adopt one of these

modifications, if removed or changed, damage

may result to your hull if precautions are not taken

to fill and/or waterproof any holes.

Loading...

Loading...