Do you have a question about the Yamato VG2700 class and is the answer not in the manual?

General guidelines and precautions for safely operating the sewing machine.

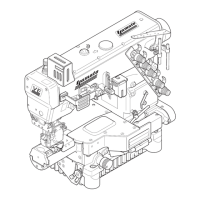

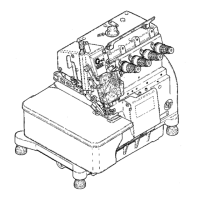

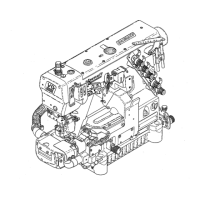

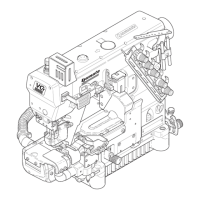

Steps and considerations for setting up the sewing machine and its components.

Procedures for keeping the machine in good working order and addressing potential issues.

Explanation of symbols and warnings used in the manual to prevent hazards.

Diagrams detailing the required cuts and dimensions for different table types.

Instructions for installing the sewing machine on a standard table top.

Guidance on selecting and installing the motor pulley and V-belt for proper operation.

Importance and installation of safety guards for operator protection.

Specifications and type of lubricating oil recommended for the machine.

Procedure for applying oil to machine parts for proper lubrication.

Instructions on how and when to change the machine's lubricating oil.

Selecting the correct needle type and size for fabric thickness and type.

Instructions for threading the needle, top cover, and looper threads for proper sewing.

Methods for adjusting thread tension based on fabric, thread, and stitch length.

Adjusting the presser foot pressure for stable fabric feeding and sewing performance.

Procedure for setting the desired stitch length, with conversion table.

Information on needle thread oiling (SP) and needle point cooling (HR) devices.

Adjusting the tension of the needle threads for optimal stitch formation and balance.

Adjustments related to the needle and spreader for correct thread path and timing.

Setting the correct distance between needles and looper for accurate stitch formation.

Adjusting the vertical position of the needles relative to the looper tip.

Procedure to adjust the differential feed range for fabric stretching or gathering.

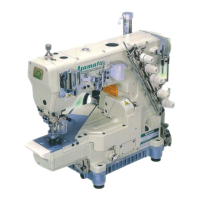

| Brand | Yamato |

|---|---|

| Model | VG2700 class |

| Category | Sewing Machine |

| Language | English |