Do you have a question about the Yamato VE2700-8 class and is the answer not in the manual?

General safety guidelines and operator responsibilities.

Defines DANGER, WARNING, and CAUTION indicators for hazard assessment.

Explains common safety symbols and their meanings for hazard communication.

Clarifies symbols used throughout the manual for better comprehension.

Essential safety measures to be followed before and during machine operation.

Lists operations where the machine's power must be turned off for safety.

Safety advice for unpacking, transportation, installation, and pre-operation checks.

Guidelines for safe machine setup, wiring, grounding, and oil handling.

Critical checks before starting the machine to prevent accidents.

Safe practices to follow while the sewing machine is running.

Procedures and precautions for safe maintenance, inspection, and repair activities.

Key points for ensuring consistent machine performance through regular checks.

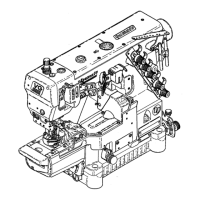

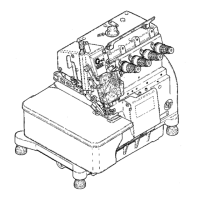

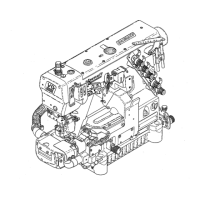

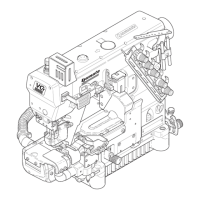

Locations and importance of safety guards, covers, and labels on the machine.

Specifies dimensions for cutting table tops for machine installation.

Step-by-step guide for mounting the sewing machine on a table top.

Instructions for fitting the sewing machine into a semi-submerged table setup.

Guidance on selecting and installing the correct pulley and belt for the machine.

Instructions for attaching the belt cover for safety and protection.

How to install safety guards for operator protection during operation.

Steps to correctly position the thread guide plate for smooth threading.

Specifies the type of oil (YAMATO SF OIL 28) and cautions against additives.

Instructions for applying oil to moving parts and checking the oil level.

Schedule and steps for draining and refilling the machine's oil.

Guidance on inspecting and replacing the oil filter for proper lubrication.

Guidance on choosing the correct needle size and type for materials.

Step-by-step instructions for inserting and tightening sewing machine needles.

Detailed procedures for threading all threads correctly for operation.

How to set and adjust the tension for all threads for optimal stitching.

Steps to set the correct pressure for the presser foot.

How to align the presser foot with needle holes for proper feeding.

Adjusting the differential feed for gathering or stretching fabric.

Methods for setting the stitch length using the adjusting knob or lever.

Procedures for adjusting fabric guides for covering seams.

Setting the pressure for the walking presser foot for smooth feeding.

Aligning the fabric edge guide for hem width control.

How to lift the upper feed roller to clear jammed material.

Adjusting the pressure of the upper feed roller for material feeding.

Usage and maintenance of the SP device for thread oiling.

Daily and weekly cleaning tasks to maintain the sewing machine.

Adjusting needle thread tension via take-up and eyelets.

Adjusting the tension and take-up amount for the top cover thread.

Setting looper thread tension and positioning the thread take-up.

Adjusting clearances between needles, spreader, and hook for proper stitch formation.

Setting the precise distance between the needle and looper tips.

How to use a timing gauge for accurate needle and looper alignment.

Correctly setting the vertical position of the needle relative to the looper.

Adjusting the horizontal position of the needle and looper for alignment.

Aligning needle guards with needles for protection and stitch formation.

Setting the correct height for differential and main feed dogs.

Adjusting the vertical travel of the presser foot.

Adjusting the tilt angle of the presser foot for specific sewing needs.

Balancing and setting the walking presser foot for proper operation.

Adjusting the feeding amount of the puller mechanism.

Setting the correct pressure for the clutch tension spring.

| Brand | Yamato |

|---|---|

| Model | VE2700-8 class |

| Category | Sewing Machine |

| Language | English |

Loading...

Loading...