GENE

RAL

INFORMATION

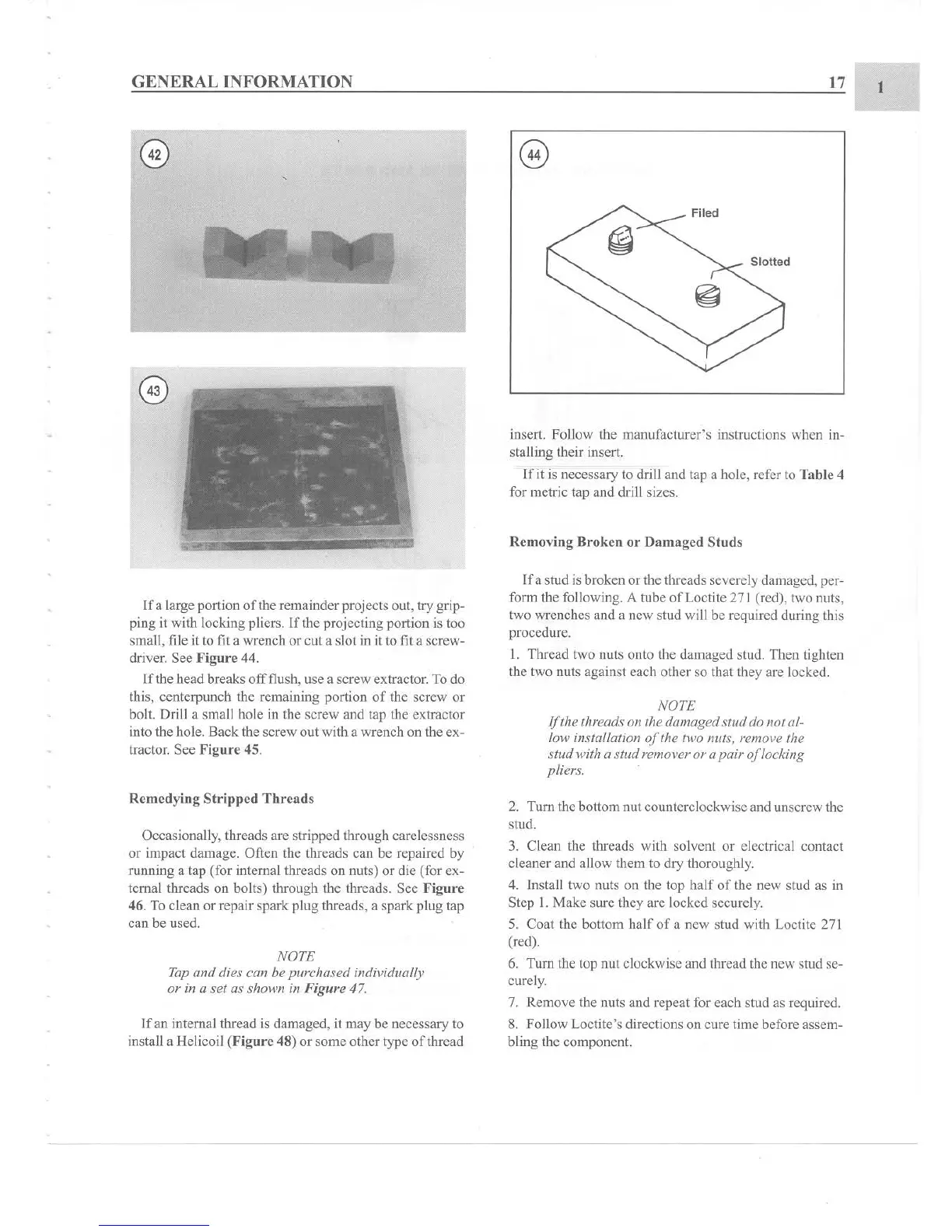

If

a large portion

of

the remainder projects out, try grip-

ping it

with locking pliers. If the projecting portion is too

small, file

it to fit a wrench or cut a slot in it to fit a screw-

driver. See Fi

gur

e 44.

If

the head breaks

off

flush, use a screw extractor. To do

this, centerpunch the remaining portion

of

the screw or

bolt. Drill a small hole in the screw and lap the extractor

into the hole. Back the screw out with a wrench on the ex-

tractor. See Figure 45.

Remedying Stripped Thre ads

Occasionally, threads arc stripped through carelessness

or impact damage. Often the threads can be repaired by

running a tap (for internal threads on nuts) or die (for ex-

ternal threads on bolts) through the threads. Sec

Figur

e

46. To clean or repair spark plug threads, a spark plug tap

can be used.

NOTE

Tap and dies can be purchased individually

or in a

set

as shown in Figure 47.

If an internal thread is damaged, it may be necessary to

install a Helicoil (Figure 48) or some other type

of

thread

17

'-

__

Filed

Slotted

insert. Follow the manufacturer's instructions when in-

stalling their insert.

I

fi

t is necessary to drill and tap a hole, refer to Table 4

for metric tap and drill sizes.

Removing Broken

or

Damaged Studs

If

a stud is broken or the threads severely damaged, per-

form the following.

A tube

ofLoctite

271 (red), two nuts,

two wrenches and a new stud will be required during this

procedure.

I . Thread IwOnuts onto the damaged stud. Then tighten

the two nuts against each other so that they are locked .

NOTE

Ifthe

threads on the damaged stud do flatal-

low installation

of

the two nuts, remove the

stud with a stud remover or a

pair

of

locking

pliers.

2.

Tum

the bottom nut counterclockwise and unscrew the

stud.

3. Clean the threads with solvent or electrical contact

cleaner and allow them 10dry thoroughly.

4. Install two nuts on the top

half

of

the new stud as in

Step 1. Make sure they arc locked securely.

5. Coat the bottom

half

of

a new stud with Loctite 271

(red).

6. Tum the top nut clockwise and thread the new stud se-

curely.

7. Remove the nuts and repeat for each stud as required.

8. Follow Loctitc's directions on cure time before assem-

bling the component.

1

Loading...

Loading...