GENERAL INFORMATION

23

@

b. Remove the housing from the oven or hot plate and

hold onto the housing with a kitchen potholder,

heavy gloves or heavy shop

cloths-it

is hot.

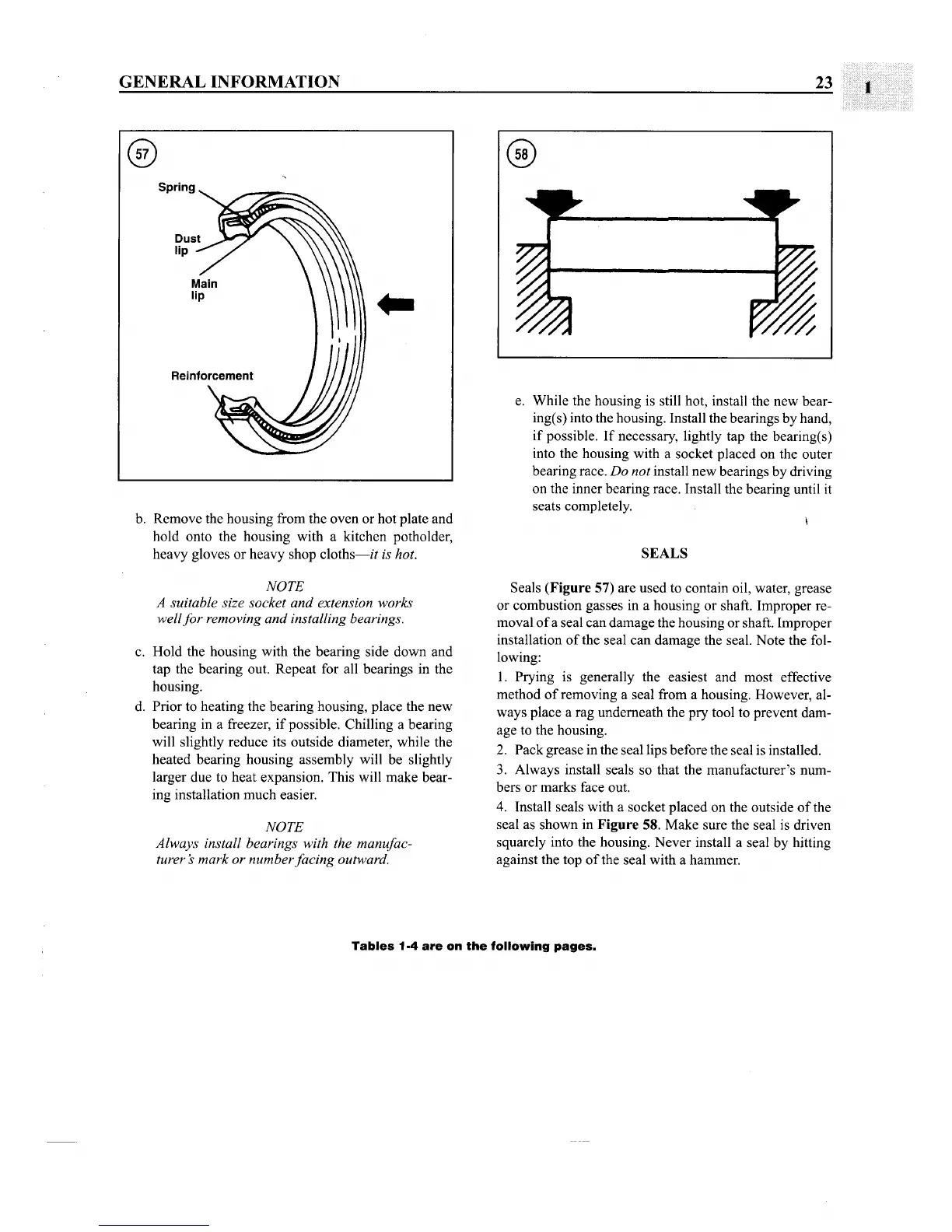

Spring

Dust

lip

..

e. While the housing is still hot, install the new bear-

ing(s) into the housing. Install the bearings by hand,

if possible. If necessary, lightly tap the bearing(s)

into the housing with a socket placed on the outer

bearing race.

Do not install new bearings by driving

on the inner bearing race. Install the bearing until it

seats completely.

SEALS

NOTE

A suitable size socket and extension works

well

for

removing

and

installing bearings.

c. Hold the housing with the bearing side down and

tap the bearing out. Repeat for all bearings in the

housing.

d. Prior to heating the bearing housing, place the new

bearing in a freezer,

if

possible. Chilling a bearing

will slightly reduce its outside diameter, while the

heated bearing housing assembly will be slightly

larger due to heat expansion. This will make bear-

ing installation much easier.

NOTE

Always install bearings with the manufac-

turer

s

mark

or numberfacing outward.

Seals (Figure 57) are used to contain oil, water, grease

or combustion gasses in a housing or shaft. Improper re-

moval

of

a seal can damage the housing or shaft. Improper

installation

of

the seal can damage the seal. Note the fol-

lowing:

1. Prying is generally the easiest and most effective

method

of

removing a seal from a housing. However, al-

ways place a rag underneath the pry tool to prevent dam-

age to the housing.

2. Pack grease in the seal lips before the seal is installed.

3. Always install seals so that the manufacturer's num-

bers or marks face out.

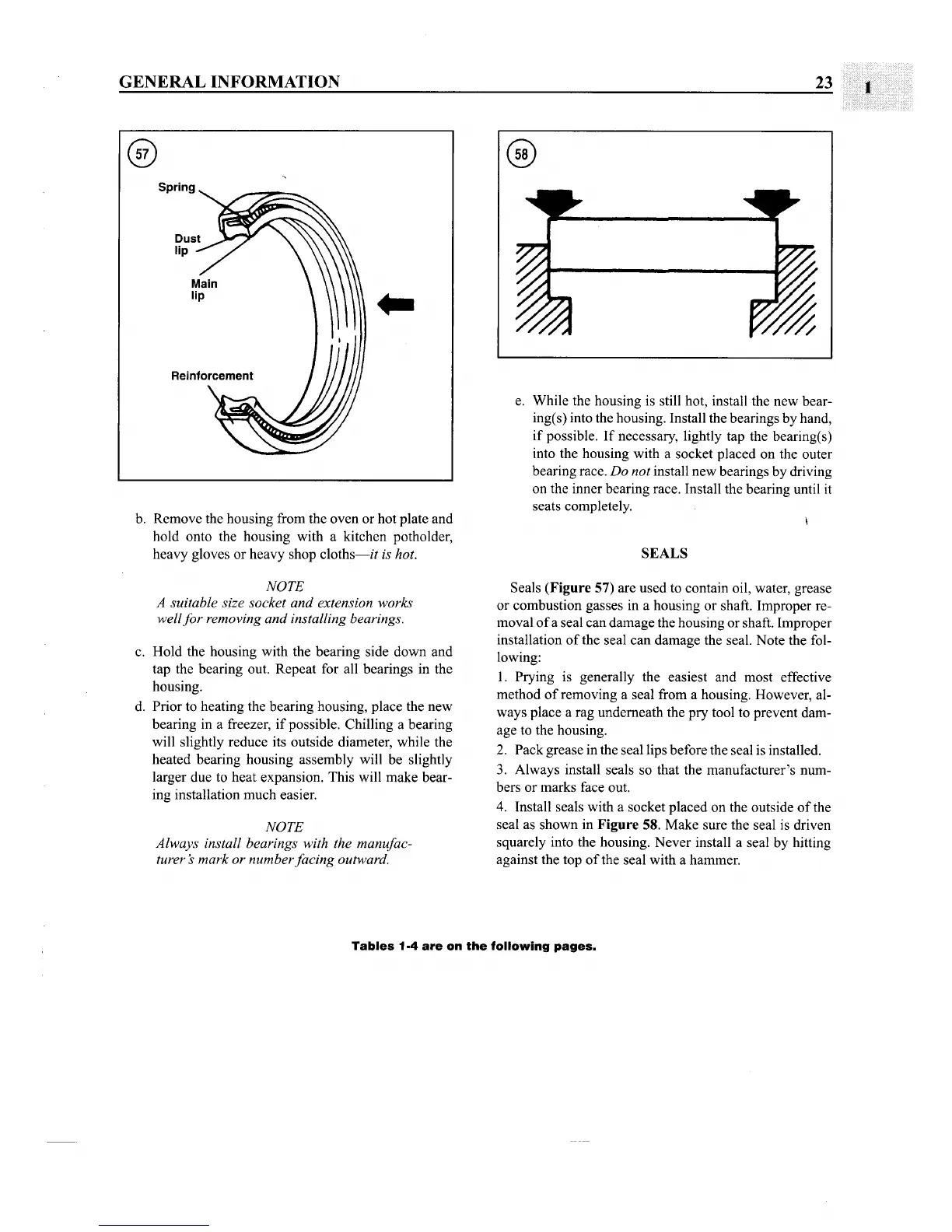

4. Install seals with a socket placed on the outside

of

the

seal as shown in

Figure 58. Make sure the seal is driven

squarely into the housing. Never install a seal by hitting

against the top

of

the seal with a hammer.

Tables

1·4

are

on

the

following

pages.

Loading...

Loading...