TROUBLESHOOTING 29

Loud

grinding noises when starter runs

Solenoid

(S) terminal

Ammeter

~

- +

Starter

motor

Voltmeter

~

+ -

+

12

volt

battery

This can be caused by improper meshing

of

the starter

pinion and flywheel ring gear or by a broken overrunning

clutch mechanism.

1. Remove the starter. See Chapter Nine.

2. Check the starter pinion gear. If the teeth are chipped

or worn, inspect the flywheel ring gear for the same prob-

lem. Replace the starter and/or ring gear as required.

3. If the pinion gear is in good condition, the overrunning

clutch mechanism in the starter may be defective. Replace

the starter with a new or rebuilt marine unit.

Starter

Solenoid Resistance Tests

Check the starter solenoid using the following resis-

tance tests:

open circuit or a loose connection. If the engine does not

start, replace the starter solenoid.

Starter spins

but

does

not

rotate flywheel

1. Remove the starter. See Chapter Nine.

2. Check the starter pinion gear. If the teeth are chipped

or worn, inspect the flywheel ring gear for the same prob-

lem. Replace the starter and/or ring gear as required.

3. If the pinion gear is in good condition, disassemble the

starter and check the armature shaft for corrosion. See

Brush Replacement, Chapter Nine, for the disassembly

procedure.

If

no corrosion is found, the starter drive mech-

anism is slipping. Replace the starter with a new or rebuilt

marine unit.

Starter will

not

disengage when start switch is released

This problem is usually causedby a sticking solenoid or

defective start switch, but the pinion may

jam

on the fly-

wheel ring gear on an engine with many hours

of

opera-

tion.

NOTE

A low battery or loose or corroded battery

connections can also cause the starter to re-

main engaged with the flywheel ring gear.

Low voltage at the starter can cause the

contacts inside the solenoid to chatter and

weld together, resulting in the solenoid

sticking in the ON position.

CAUTION

Disconnect the negative battery cable be-

fore

performing resistance tests.

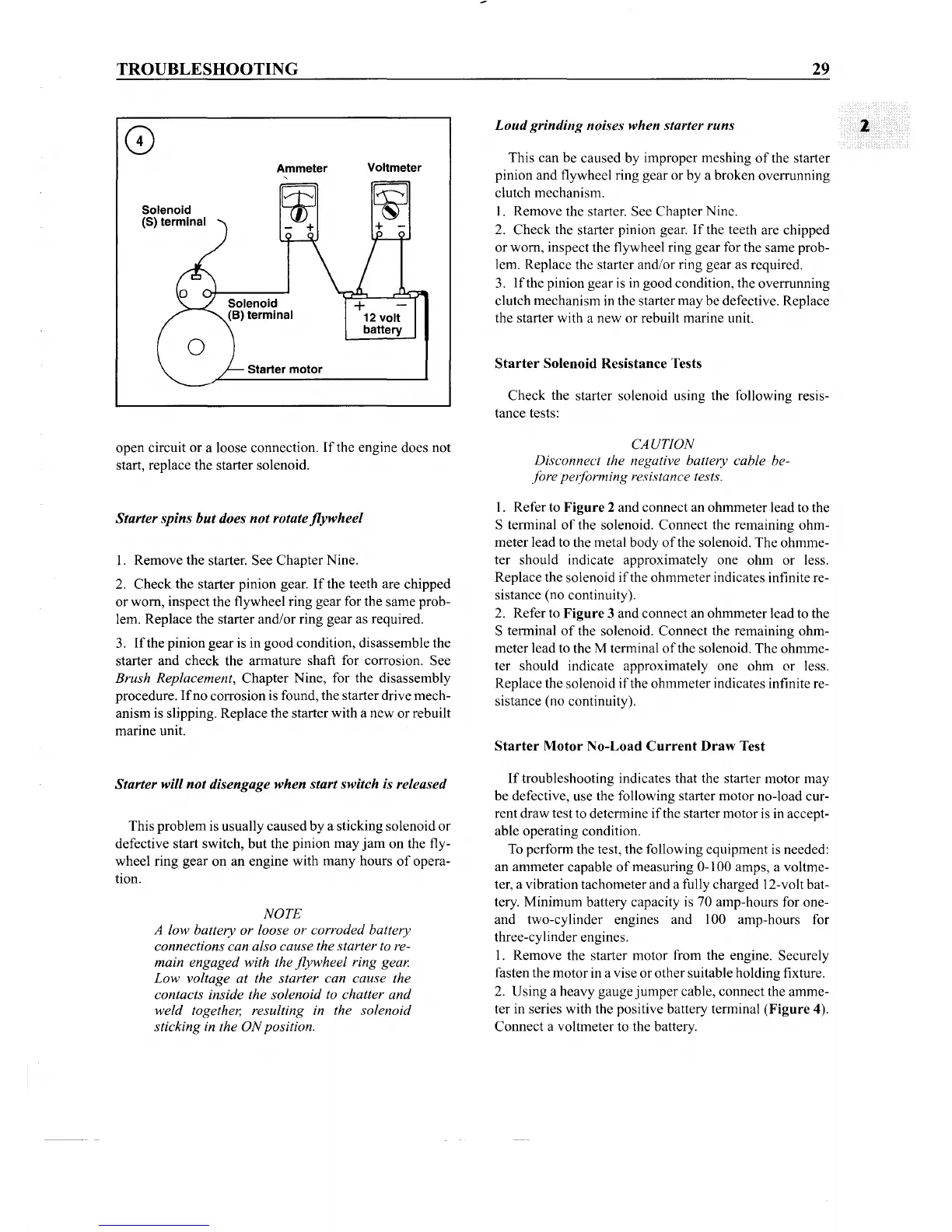

I. Refer to

Figure

2 and connect an ohmmeter lead to the

S terminal

of

the solenoid. Connect the remaining ohm-

meter lead to the metal body

of

the solenoid. The ohmme-

ter should indicate approximately one ohm or less.

Replace the solenoid

if

the ohmmeter indicates infinite re-

sistance (no continuity).

2. Refer to

Figure

3 and connect an ohmmeter lead to the

S terminal

of

the solenoid. Connect the remaining ohm-

meter lead to the M terminal

of

the solenoid. The ohmme-

ter should indicate approximately one ohm or less.

Replace the solenoid

ifthe

ohmmeter indicates infinite re-

sistance (no continuity).

Starter

Motor

No-Load

Current

Draw

Test

If troubleshooting indicates that the starter motor may

be defective, use the following starter motor no-load cur-

rent draw test to determine

if

the starter motor is in accept-

able operating condition.

To perform the test, the following equipment is needed:

an ammeter capable

of

measuring 0-100 amps, a voltme-

ter, a vibration tachometer and a fully charged 12-volt bat-

tery. Minimum battery capacity is 70 amp-hours for one-

and two-cylinder engines and 100 amp-hours for

three-cylinder engines.

1. Remove the starter motor from the engine. Securely

fasten the motor in a vise or other suitable holding fixture.

2. Using a heavy gauge jumper cable, connect the amme-

ter in series with the positive battery terminal (Figure 4).

Connect a voltmeter to the battery.

Loading...

Loading...