LAY

-UP

AND

FITTING

OUT

Heat

-

-'l-

-T

~

'

exc

hanger

2. On 3GM, 3GM30, 3HM and 3HM35 engines, open the

drain on the underside

of

the exhaust manifold (Fi

!!:

ure 1,

typical).

3. Open the drain on the cylinder block (Fig

ur

e 2, typi-

cal).

4. Remove the lower end

of

all cooling system hoses

from the engine, pump and exhaust manifold. Lower the

hoses and allow them to completely drain. Reconnect the

hoses and clamp securely.

,VOTE

On

IGM

and IGMIOengines. access is re-

stricted to the upper water pump cover

sere",·:

If a suitable tool is not available, it

may be necessary to remove the cranksha

ft

pulley

jor

access to afl

of

the water pl/mp

cover screws.

65

5. Loosen the cover screws on the seawater pump (Fig-

ure 3, typical) and drain any water in the pump. lf thc gas-

ket is damaged. remove the cover and install a new gasket

and the cover.

6. Allow the cooling system to drain completely, then

close all drains.

Adding

ant

if

reeze

The following procedure pertains to seawater cooling

systems and is designed to provide additional protection

against damage due to freezing temperatures

while the

boat

is in storage.

C.AUTION

Do not

nm

the engine after

perfo

rming the

storage service procedure tnat fotlows. Be-

fore returning the hoat

to

service, drain the

seawater

cooling system as described in this

chapter.

I. Refer to Chapter Eight to remove the thermostat and

gasket. Discard the gasket.

2. Make sure the scacock or water inlet to the seawater

pump is closed .

3. Pour a

50/50 solution

of

pure soft water and ethylene

glycol antifreeze through the thermostat hole into the en-

gine until the cylinder

head, block and manifold arc full,

4. Reinstall

the thermostat with a new gasket.

Fr

eshwater (Closed) Cooling Syste m

The freshwater section

ofa

cooling system need not be

drained during winter months, provided it is

filled with a

50/50solution

of

pure soft water and ethylene glycol anti-

freeze. However, if draining the freshwater cooling

sys·

tern is necessary, usc the following procedure.

Note that the following procedures address the freshwa-

ter and seawatersections

of

the cooling system separately.

If the freshwater portion is not being drained, follow the

draining procedure for the seawater section.

Freshwater (cl

oud)

cooli

ng

section

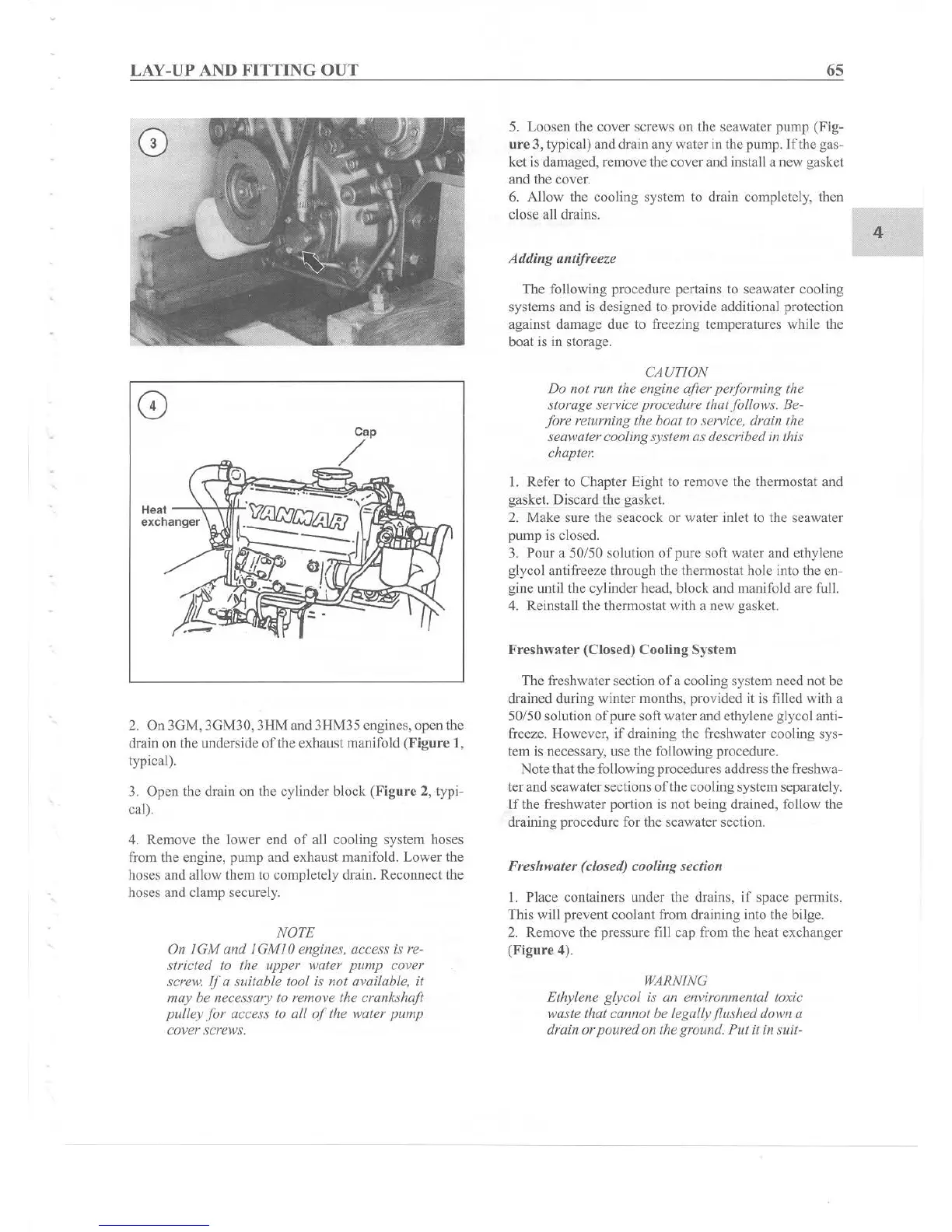

I. Place containers under the drains, if space permits.

This

will prevent coolant from draining into the bilge.

2. Remove the pressure fill cap from the heat exchanger

(Figure

4).

WARNING

Ethylene glycol

is

WI

environmental toxic

waste that cannot he legally

flushed

down a

drain

or

pouredon the ground. Put it in suit-

4

Loading...

Loading...