11

When rigging for overhead lift, attach

shackle bolts to the lifting lugs. Bring the

four individual rigging cables together at a

point high enough that the angle between the

rigging line and the top of the unit is no less

than 60°, as shown in the Figure 4. This will

require cable lengths a minimum of 36” (1m)

for all sizes except the WFC-SC50 which will

require 48” (1.3m) cable length.

There are times when the unit simply

cannot be moved to the final installation site

while remaining in the vertical position. It is

be permissible to lay the unit on its side, so

long as proper precautions and guidelines

are followed.

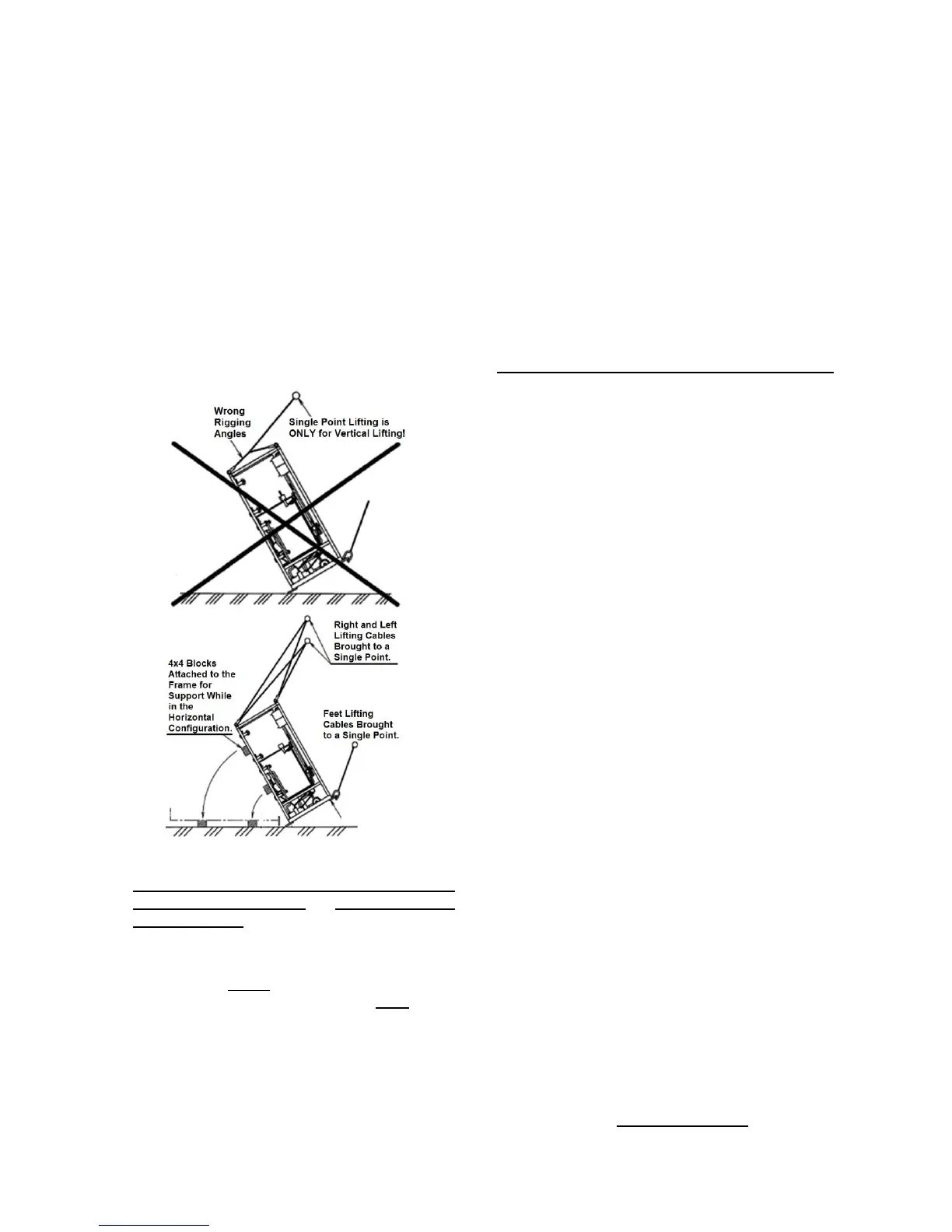

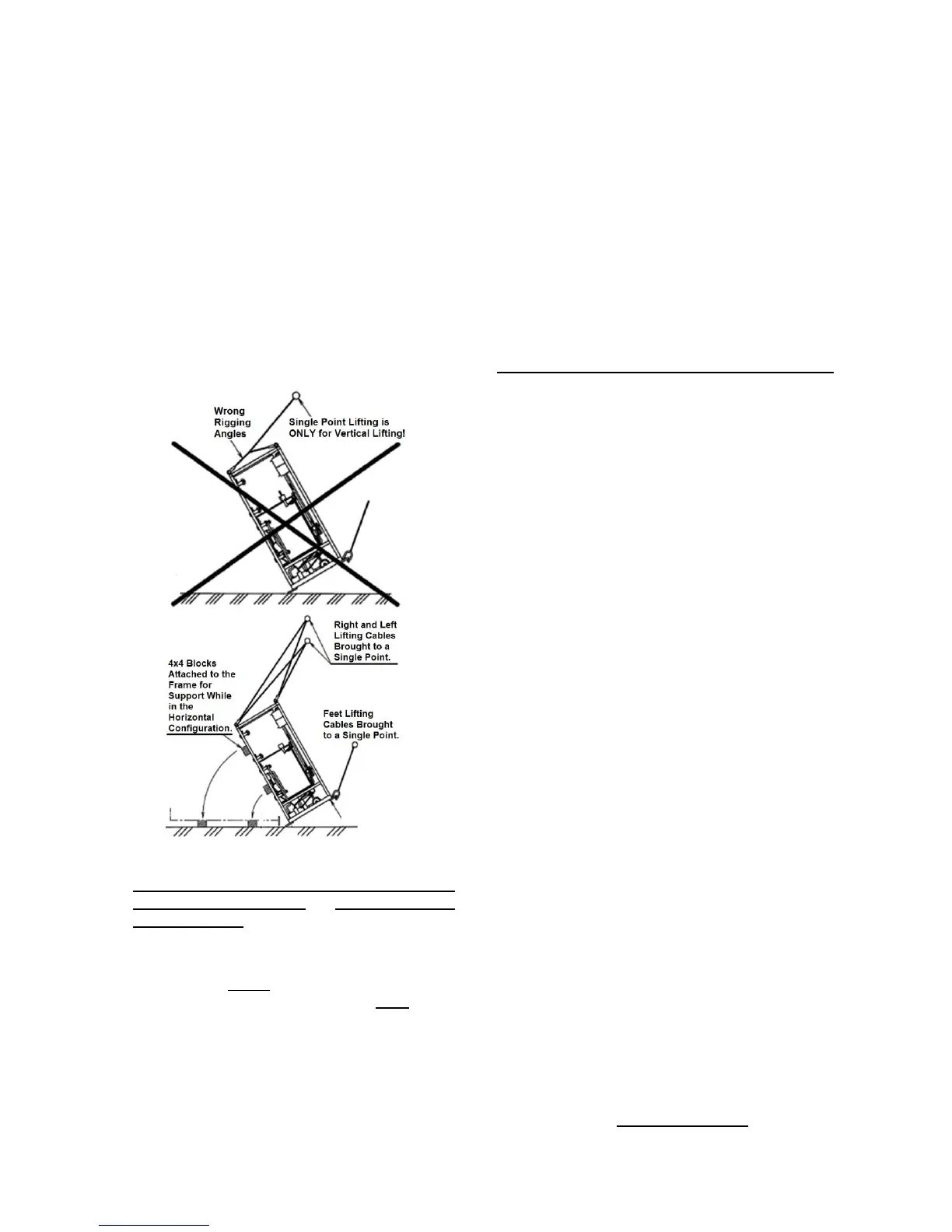

Figure 5 – Laying the Unit on its Side

1. Transport by vehicle ONLY with the unit in

vertical configuration. THERE IS NO

ALTERNATIVE. Transport by vehicle over

roadway while the unit is not in the vertical

configuration will void the warranty.

2. The unit may ONLY lay onto its back - the side

with the water connections. It may NOT lay on

any other side!

a. While on its back, the water piping acts as

legs to support the internal tubing bundles.

On any other side, the tubing bundles will

not be properly supported and may shift or

become severely damaged, rendering the

machine inoperable.

3. Do not simply tip the unit over onto its back. It

should be lifted and turned to the horizontal

configuration while fully supported and

suspended, though it only need be barely off

the ground while turning.

4. DO NOT lay the unit directly onto the ground

in a manner that will allow the water

connections support the weight of the unit.

Attach 4x4 blocks or timbers to the frame for

support in the horizontal configuration.

5. DO NOT USE A SINGLE POINT LIFTING

when laying the unit onto its side. At least

THREE lifting points will be necessary.

To properly lay the unit onto its side:

1. Remove all cabinet panels in order to prevent

damage to them.

2. Attach 4x4 blocks or timbers to the rear frame

to act as support feet while the unit is in the

horizontal configuration.

3. Attach two rigging cables to the unit feet

across the front of the unit. Bring these cables

to a single point, maintaining a minimum of

60° between unit and cable.

4. Attach two rigging cables to the left side lifting

lugs. Bring these cables to a single point.

5. Attach two rigging cables to the right side

lifting lugs. Bring these cables to a single

point.

6. Using these three points, lift the unit slightly off

the ground, using the lifting cables on the feet

to rotate the unit onto its back. Use the right

and left side lifting cables to control the

sideways rotation.

7. Once the unit is in the horizontal configuration,

let it gently rest on the blocks that were

attached during step 2.

8. Once the unit is to be turned back to the

vertical configuration, it is preferable that the

unit again be lifted and rotated in the same

manner as described above. However, in

cases where mechanical lifting is not available

at the installation site, the unit CAN tilted over

onto its feet.

Do not let the unit fall hard onto its feet.

Do not allow the feet to become deformed.

Be mindful of the considerable mass of

the unit (refer to the Specifications page).

Using human power alone to tip the unit is

not advised as it could become a very

dangerous and potentially deadly procedure.

Loading...

Loading...