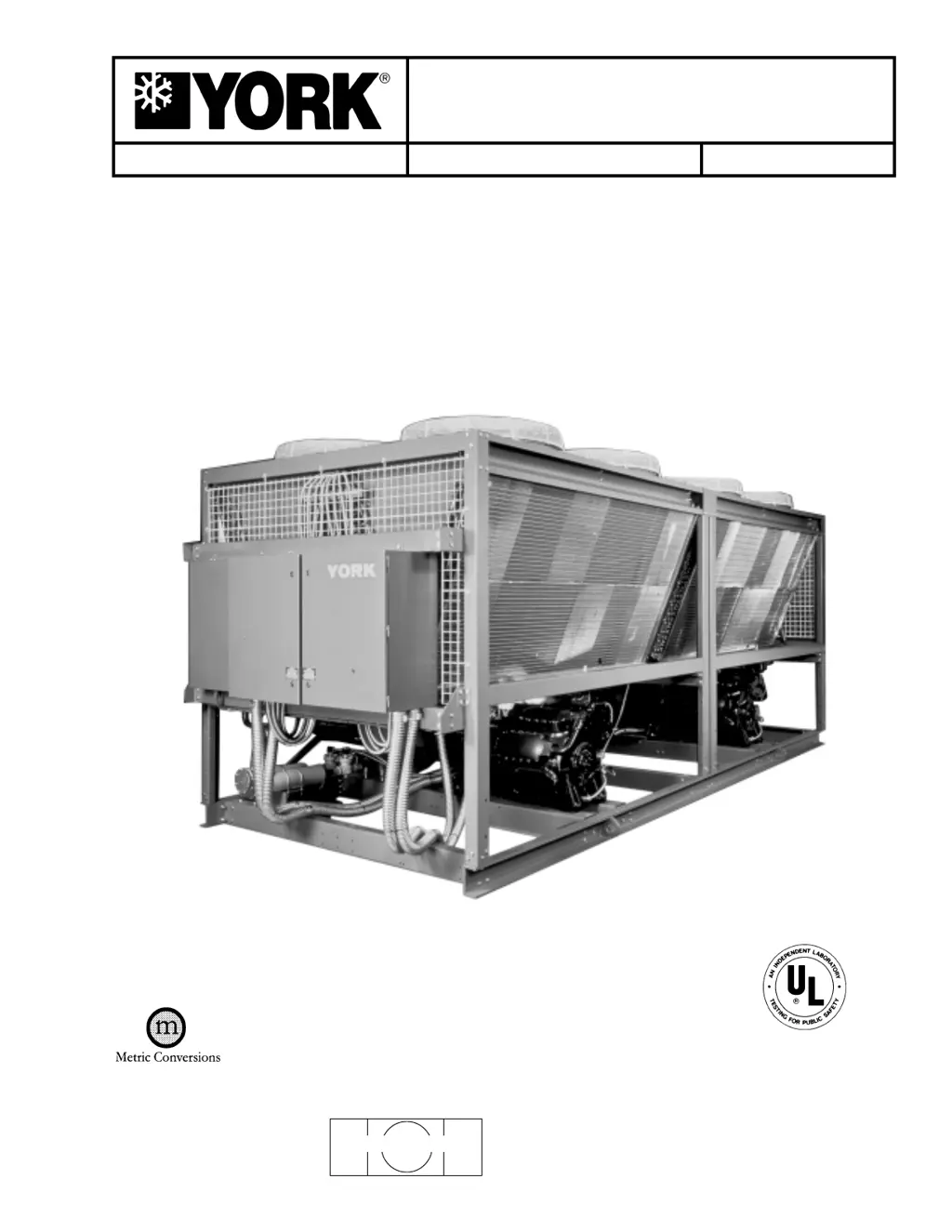

Why does my York Millennium YCAJ150 show a 'MOTOR CURRENT' fault?

- MMichael RogersAug 4, 2025

A 'MOTOR CURRENT' fault on your York Chiller can stem from several causes. The external high-pressure switch might have tripped, so check the switch, fan operation, and discharge pressure. An external motor protector might have tripped; inspect the protector, wiring, and motor. Also, a defective relay output board, improper system high voltage, defective contactor contacts, faulty high voltage wiring, or high motor current stored in memory could be the cause. Check the system's high voltage supply, contactors and wiring. Loose calibration resistors in J9 (SYS 1) or J10 (SYS 2) of the power supply board or a defective current transformer (CT) can also trigger this fault.