ZEKS Eclipse ZPA 90-5000 Desiccant Dryers

www.zeks.com

10

9.0 MAINTENANCE AND SYSTEM CHECK

9.1 SCHEDULED MAINTENANCE

DAILY MAINTENANCE FUNCTIONS:

• Check and record inlet pressure, temperature and fl ow.

Verify that it is within specifi cations.

• Check tower pressure gauge readings within operating

tolerance.

• Check operation for proper dryer cycling, depressuriza-

tion and repressurization.

• Check that the prefi lter drain is operating properly and

that there is no condensate discharged from purge muf-

fl ers.

• Verify that pressure in purging tower is 10 PSIG or less. If

higher, muffl er replacement is recommended. See SEC-

TION 10.

• Verify that prefi lter and afterfi lter differential pressure is

within operating limits. Replace elements and/or cartridg-

es as required. See SECTION 9.1 Semi-Annual Mainte-

nance.

• Check the Blue Moisture Indicator. Make sure air is

bleeding through the indicator. The indicator will be blue

when air is dry.

SEMI-ANNUAL MAINTENANCE FUNCTIONS:

• Check outlet dew point.

• Check pilot air fi lter element and clean or replace as

required.

• Replace prefi lter and afterfi lter elements and/or

cartridges.

ANNUAL MAINTENANCE FUNCTIONS:

• Check desiccant and replace if necessary.

• Inspect and clean pilot air control solenoid valves, check

valves and diaphragm valves. Rebuild and / or replace

as required.

• Test lights and switches, replace as necessary.

• Test electrical components, replace as necessary.

EVERY TWO YEARS:

• Replace diaphragm and seal kits on purge and switching

diaphragm valves.

EVERY THREE-TO-FIVE YEARS:

• Rebuild purge and switching diaphragm valves (Preven-

tative).

• Replace Check Valves (Preventative).

9.2 PREFILTERS AND AFTERFILTERS

PREFILTERS - The cartridges of the prefi lter must be

changed as often as required to prevent contamination of

the regenerative dryer’s desiccant bed.

The prefi lter and automatic drain must be checked daily.

To prolong fi lter cartridge life, it is recommended that a

mechanical air / moisture separator be placed immediately

before the prefi lter.

AFTERFILTERS - The purpose of the afterfi lter is to re-

move residual desiccant dust. Depending upon equipment

application and usage, frequency of fi lter element change

will vary. It is recommended that, at the minimum, the fi lter

element be changed every six months.

9.3 PILOT AIR CONTROL SOLENOID VALVES

The length of time the pilot air valves can reliably oper-

ate without replacement is dependent upon the type of

dryer and the dryer’s operation. On ZEKS -40°F dewpoint

dryers, replacing the valves every 60 months is recom-

mended. Given the difference in cycle times for -80°F and

-100°F units, these dryers should have their pilot valves

replaced every 30 months.

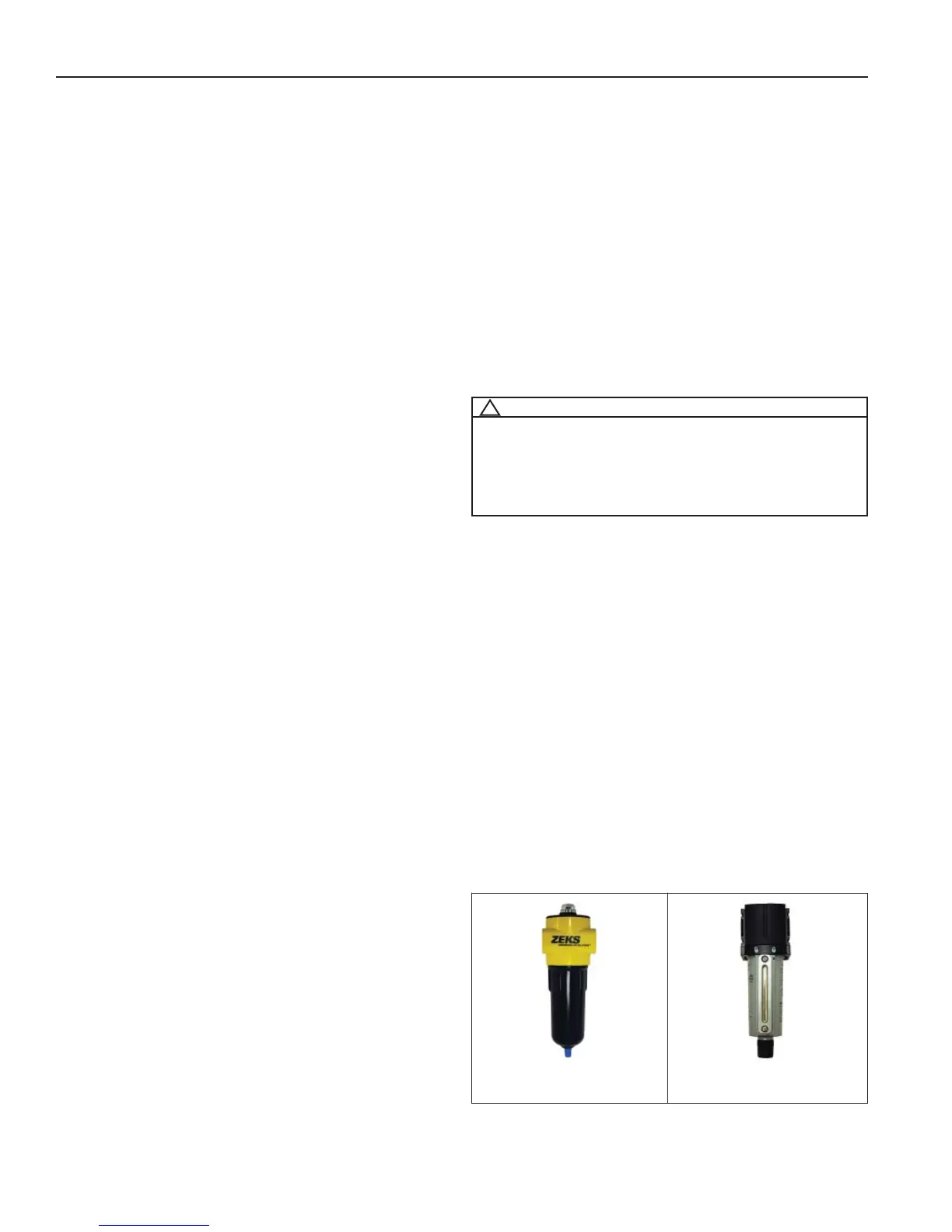

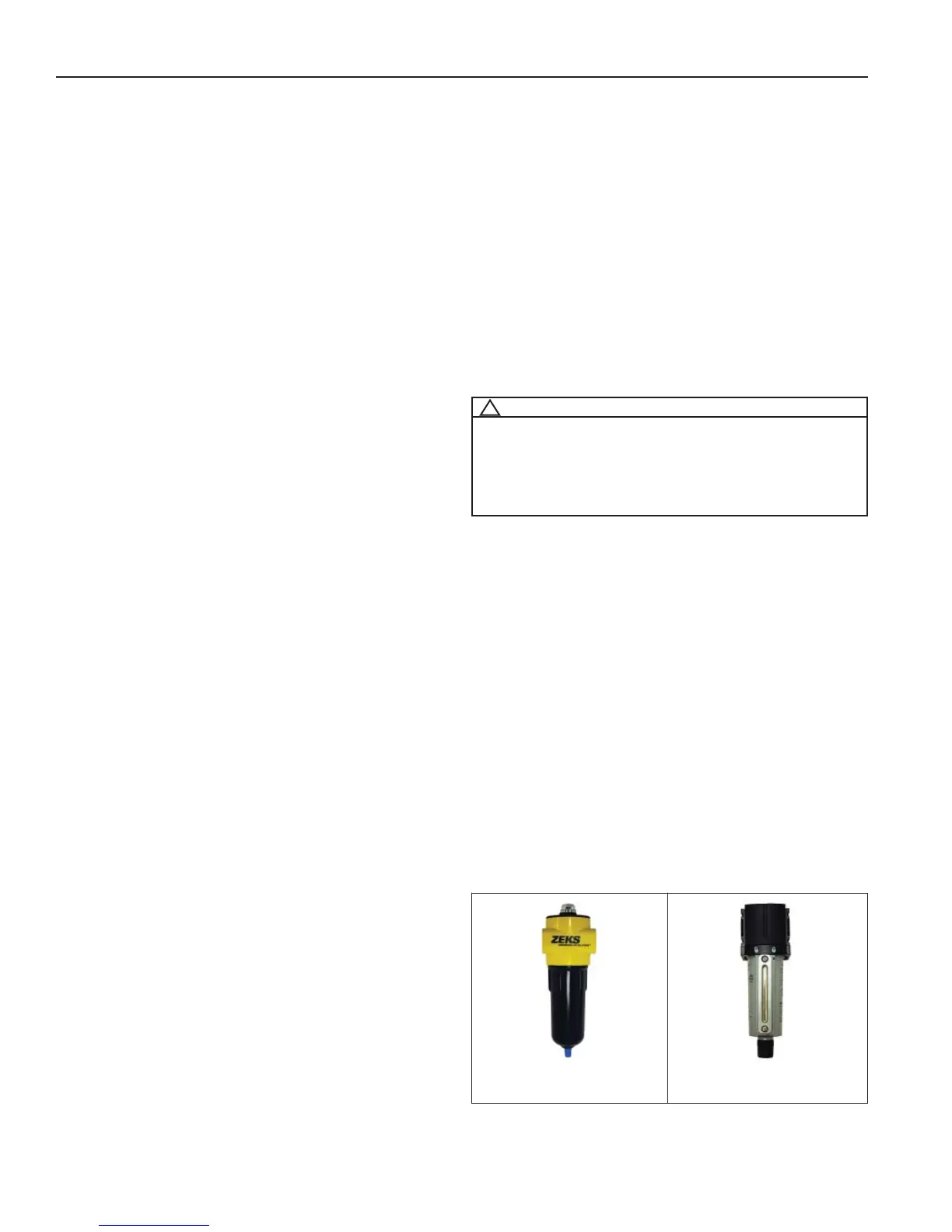

PILOT AIR FILTER ELEMENT IDENTIFICATION AND

REPLACEMENT

To determine the correct replacement element for the

Pilot Air Filter on the dryer, visually identify the fi lter that

is mounted on the right side of the Electrical Enclosure

and compare it to the options shown below. Select the

replacement element that matches the Pilot Air Filter and

use the corresponding Part Number when ordering.

!

NOTICE

Should the drying system be overloaded and/or

malfunctioning, causing high pressure drop, afterfi lters

may prematurely plug. This problem can be avoided

by frequent inspection and proactive replacement of

cartridges.

Use Replacement Element

Part No.: E15H

Use Replacement Element

Part No.: 104424

Loading...

Loading...