Non-Sound Decoder MX600 - MX638 and Sound Decoder MX640 - MX659 Page 35

Automatic disengage-

ment after uncoupling

=

“Automatic uncoupling”

Tens digit (0 – 9): Length of time the loco should move

away (disengage) from the train; coding as in CV

#115.

Ones digit (0 – 9) x 4 = Internal speed step applied for

disengagement (Momentum per CV #3 etc.)

Hundredths digit = 0: No unloading.

= 1: Coupler unloading: engine

moves toward train in order to relieve coupler tension,

before uncoupling and disengaging from the train.

Example:

CV #115 = 61: Loco uncouples and drives away from

train for 2 seconds at speed step 4.

CV #116 = 155: Loco pushes against train first to un-

load couplers, uncouples and then drives away from

the train for 1 second at speed step 20.

Notes to automated uncoupling with coupler-unloading and train disengagement

- The automatic train disengagement is active if the tens digit in CV #116 is other than 0; if desired with prior coupler

unloading (when CV #116 > 100).

- The automatic train disengagement (or the preceding coupler unloading) is started at the same time the coupler is

activated, but only if the train is standing still (speed 0); if the train is still moving, the uncoupling, unloading and

disengagement procedure won’t start until the train comes to a full stop.

- The procedure terminates when the “temporary” function key is released (or pressed again if in latched mode), or

when the predetermined times (CV #115 for the coupler, CV #116 for the disengagement) have expired.

- The uncoupling and disengagement process is aborted immediately if the speed regulator is operated at the same

time.

- The driving direction for the train disengagement is always according to the cab setting; directional settings in the

“special effects” definition for uncoupling (Bits 0 and 1 of CV #127, CV #128 etc.) will not be applied.

3.25 SUSI-Interface and Logic-Level Outputs (NOT for MX621)

All decoders described in this manual (except MX621) have outputs that can either be used as a SU-

SI interface, as logic level outputs or for servo control. These outputs are available at solder pads or

on the decoder plug (MTC or PluX), see the various decoder pin-outs starting on page 5.

These outputs are active as SUSI interface by default. To switch them to logic level outputs, config-

ure CV #124 as follows:

CV #124 = 128 or +128 (= Bit 7 in addition to other possibly set bits).

These logic level outputs are then always regarded as the next "normal" outputs. For example: The

MX630 comes with a total of 6 function outputs (Lfor, Lrev, FO1 – FO4). The two logic level outputs

are controlled as FO5 and FO6.

If these outputs are needed for servo control, leave CV #124, Bit 7 = 0 and define CV’s #181 and 182

instead (see next chapter “Servo configuration).

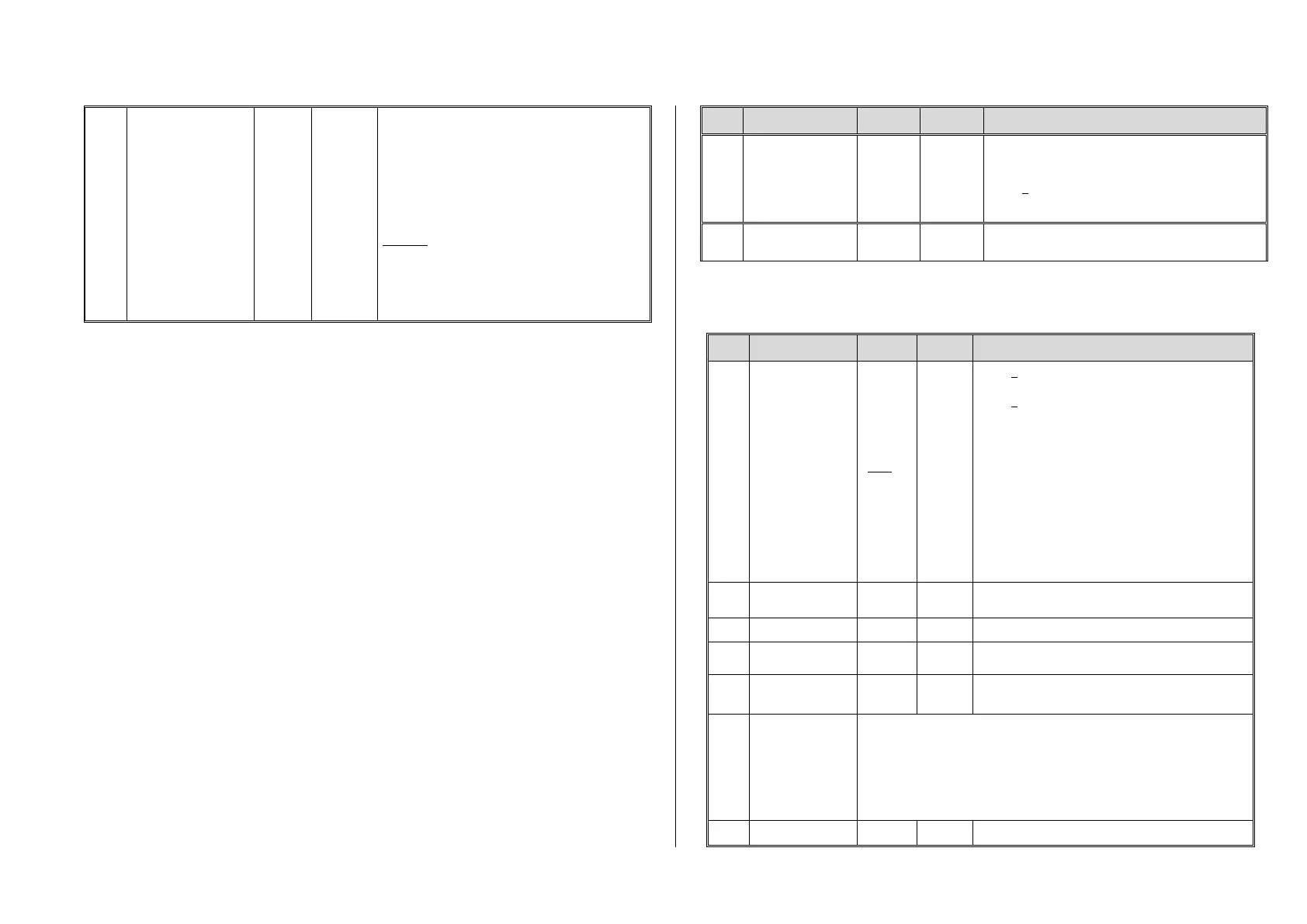

Shunting key

functions:

Changing SUSI

outputs

Bits 0 - 4, 6: Shunting key selection and

HALF-SPEED ACTIVATON

Bit 5 = 1: “ DC stopping”

Bit 7 = 0: SUSI is active (or as servo outputs if defined

as such in CV’s #181 and 182).

= 1: Logic level function outputs instead of SUSI

Bit 2 = 1: I²C an SUSI-Interface. This is an OEM feature.

For more details contact www.zimo.at

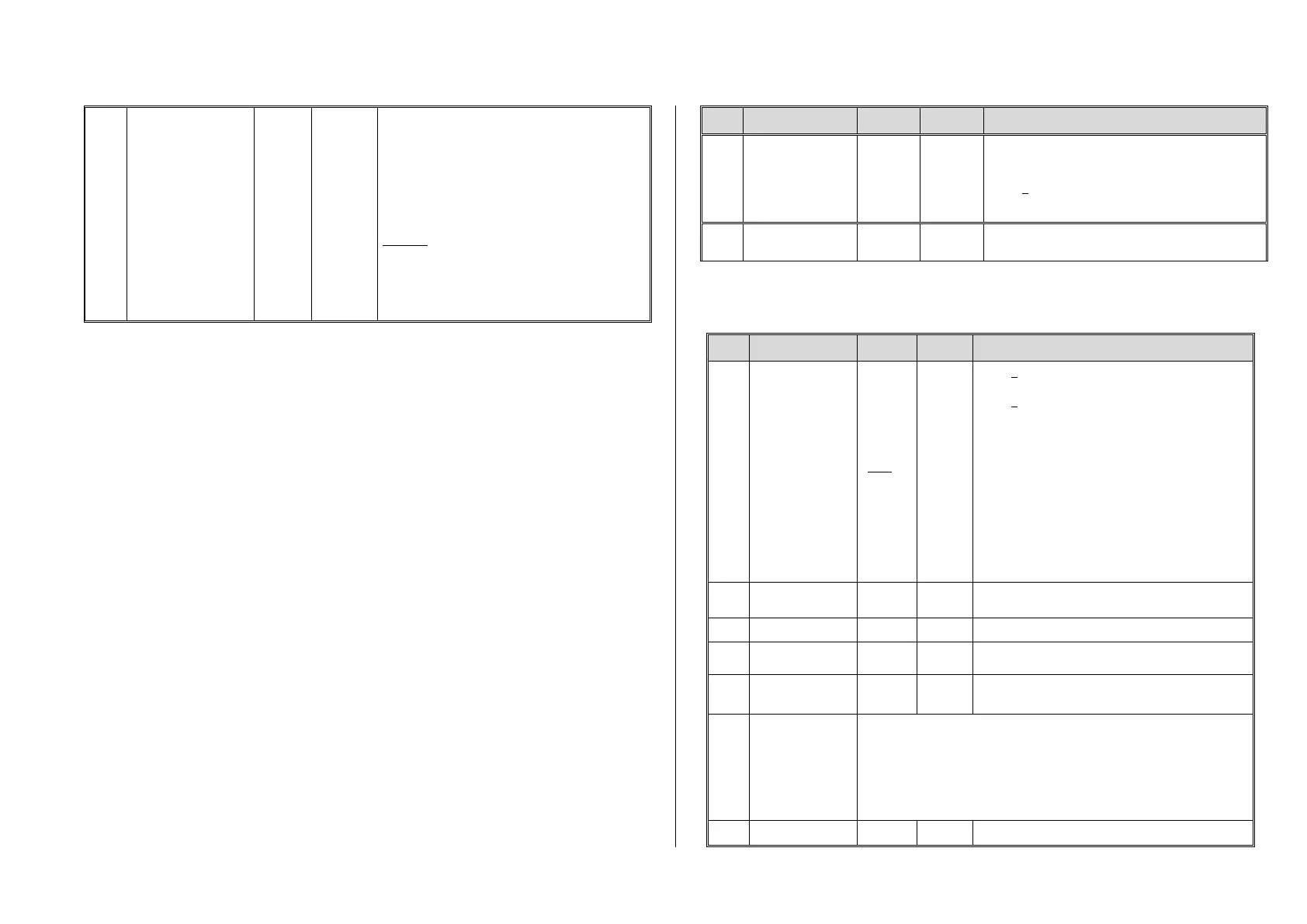

3.26 Servo Configuration (NOT for MX621)

Servo outputs:

Protocol

and alternative

use of

servo outputs 3 & 4

as SUSI

NOT for MX621

0 - 3

0

Note:

CV #161

must be

set to “2”

for

Smart

Servo

RC-1!

Bit 0 = 0: Servo protocol with positive pulses.

= 1: Servo protocol with negative pulses.

Bit 1 = 0: Control wire only active during movement

= 1: … always active (consumes power, vibrates

at times but holds position even under

mechanical load) – this setting is also required

for SmartServo RC-1 (with memory wire)!

Bit 2 = 0: For two-key operation, with center position (as

per CV #181/182) when both function keys

are OFF.

= 1: For two-key operation (as per CV #181/182),

where the servo runs only as long as function

keys are active.

Bit 3 = 1: Servo outputs 3 and 4 are used for SUSI Data

and SUSI clock (only for decoders that actually

have 4 servo outputs).

Defines the servo’s left stop position. “Left” may become

the right stop, depending on values used.

Defines the servo’s right stop position.

Defines a center position, if three positions are used.

Rotating speed; Time between defined end stops in

tenths of a second (total range of 25 sec, default 3 sec.).

#166

- 169

#170

- 173

#174

- 177

As above but for

Servo 2

Servo 3

Servo 4

#166 left stop, #167 right stop, #168 center position, #169 rotating speed.

#170 left stop, #171 right stop, #172 center position, #173 rotating speed.

#174 left stop, #175 right stop, #176 center position, #177 rotating speed.

= 0: Servo not in operation

Loading...

Loading...