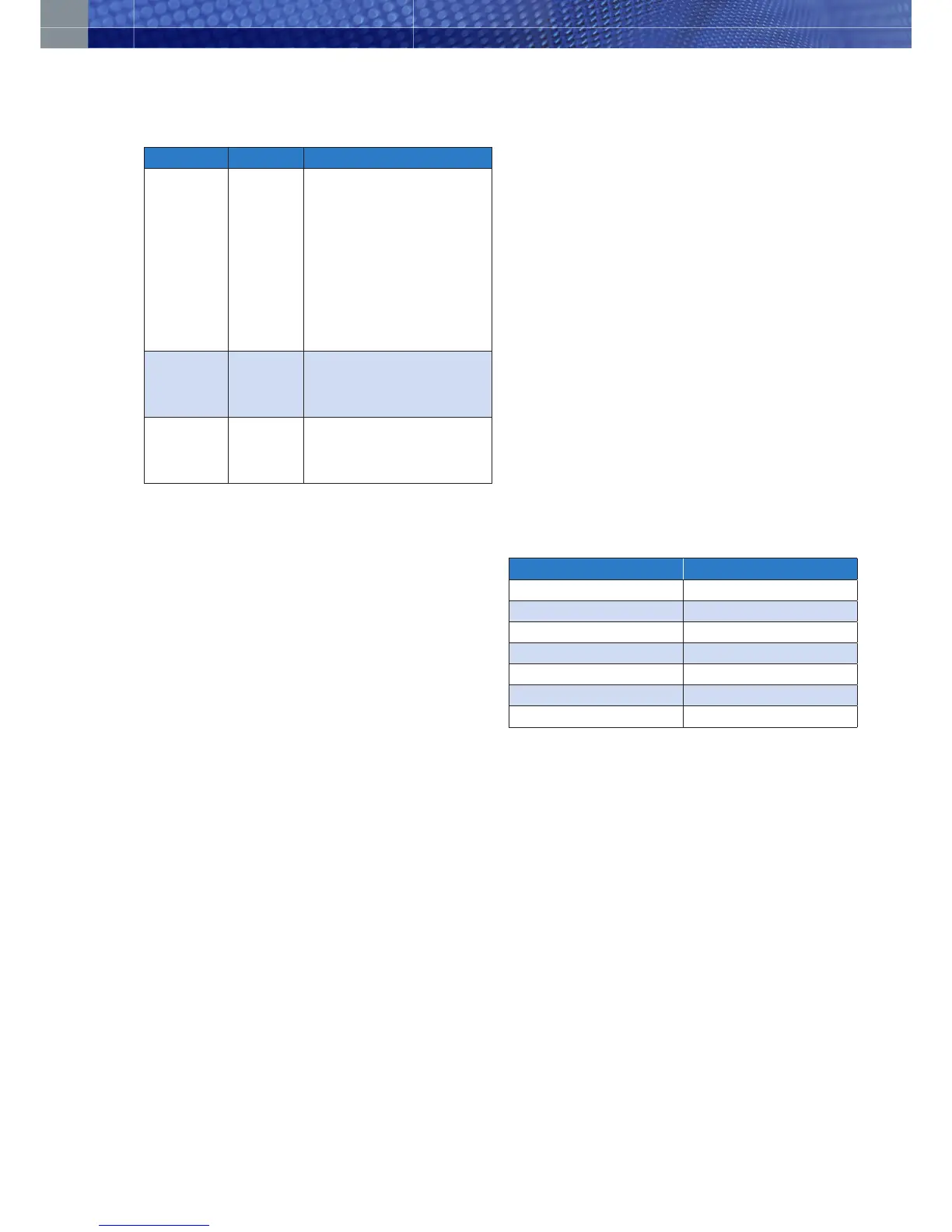

Filter Table

Filter Hazard Industry

4251

(FFA1P2 R D)

4255

(FFA2P3 R D)

Organic Vapours

and Particulates

• Anywhere conventional paints are used.

(non-Isocyanates, subject to usage

conditions)

• Vehicle manufacture

• Plant equipment manufacture

• Shoe treatment and tanneries

• Domestic appliance manufacture

• Aircraft manufacture and refurbishment

• Boat building

• Machinery manufacture

• Chemical manufacture and handling

• Ink and dye manufacture and usage

• Adhesive manufacture and laboratories

• Paint and varnish manufacture

• Manufacture and use of resins

4277

(FFABE1P3 R D)

Organic Vapours,

Inorganic Gases,

Acid Gases and

Particulates

As 4251 but also:

• Electrolytic processes

• Acid cleaning

• Metal pickling

• Metal etching

4279

(FFABEK1P3 R D)

Organic Vapours,

Inorganic and

Acid Gases, plus

Ammonia and

Particulates

As 4277 but also:

• Manufacture and maintenance of

refrigeration equipment

• Agrochemicals

Standards and Approval

The 3M™ 4000 Series Respirators meet the performance

requirementsoftheEuropeanStandardEN405:2001+A1:2009

for valved filtering half-mask respirators for gases, vapours and

particulate combinations.

The 3M™ 4000 Series Respirators have met the requirements

oftheEuropeanCommunityDirective89/686/EEC(Personal

ProtectiveEquipmentDirective)andarethusCEmarked.

CerticationunderArticle10,ECType-Examination,hasbeen

issuedfortheseproductsbyINSPECInternationalLimited,56

LeslieHoughWay,Salford,GreaterManchesterM66AJ,UK

(NotiedBodynumber0194).CerticationunderArticle11,EC

qualitycontrol,hasbeenissuedbyBSIProductServices(Notied

Bodynumber0086).

Cleaning and Storage

If the respirator is to be used for more than one shift it should

be cleaned at the end of each shift and stored between shifts

in the original packaging. To clean the respirator, the faceseal

should be wiped with a cloth moistened in warm soapy water

(thewatertemperatureshouldbebelow40°C)anddriedatroom

temperature.TheproductMUSTNOTbeimmersedinwater

duringcleaning.Alternatively,facesealmaybecleanedusingthe

3M™105FaceSealCleaner.Alwayscheckthattheproducthas

notexceededtheusebydatebeforeuse.

RespiratoryProtectionisonlyeectiveifitiscorrectlyselected,

ttedandwornthroughoutthetimewhenthewearerisexposed

to respiratory contaminants.

3M oers advice on the selection of products, and training in the

correct fitting and usage.

For more information on 3M products and services please call the

3M Health & Safety Helpline.

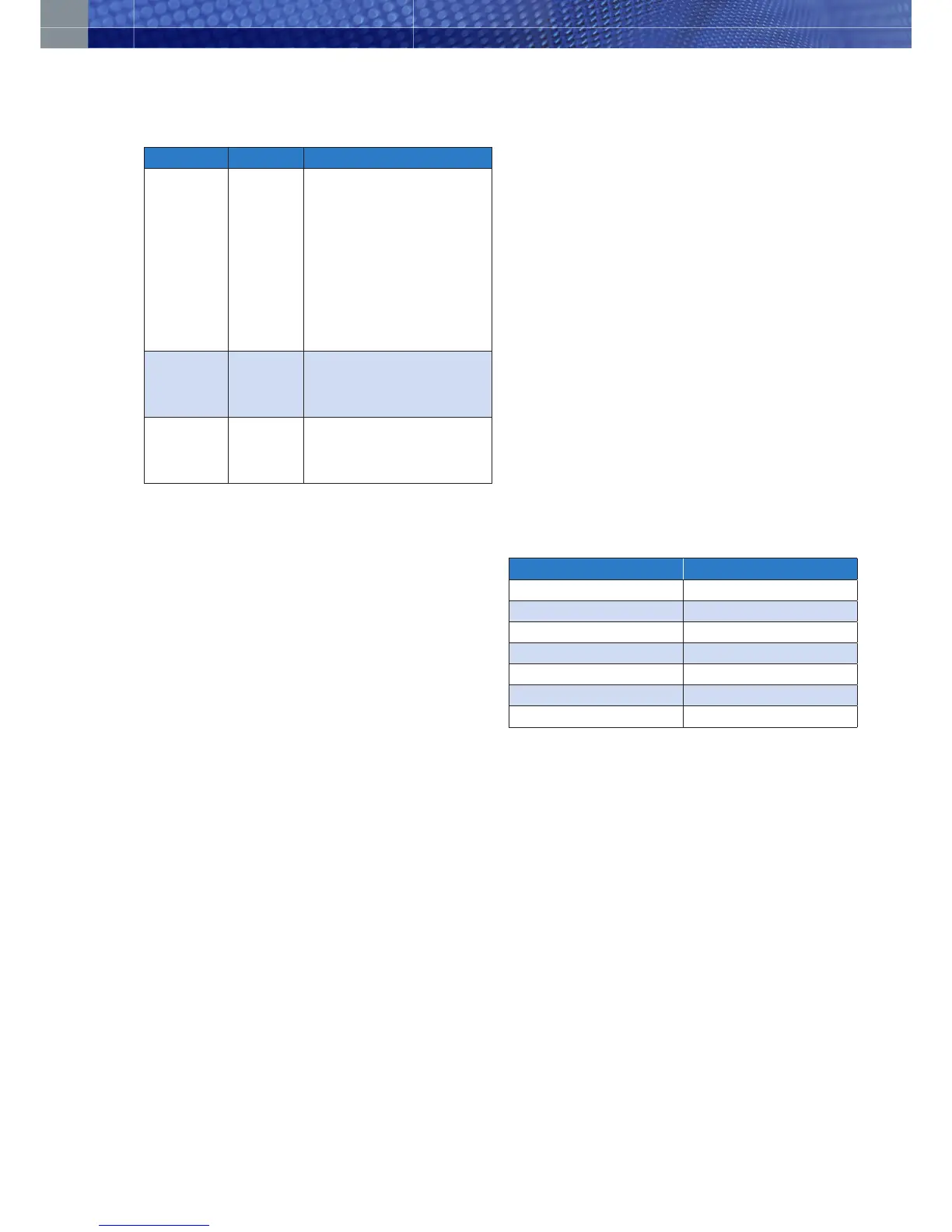

Materials

Component Material

Facemask Thermoplastic elastomer

Head Harness Polypropylene

Head Strap Polypropylene/cotton

Inhalation Valve Polyisoprene

Exhalation Valve Silicone Rubber

Gas and Vapour Filter Body Activated Carbon

Particulate Filter Element Polypropylene

Loading...

Loading...