14

Table 1 – Inspection and Maintenance Log

Serial Number(s): Date Purchased:

Model Number: Date of First Use:

Inspection Date: Inspected By:

Component: Inspection: (See Section 2.2 for Inspection Frequency) User Competent

Person

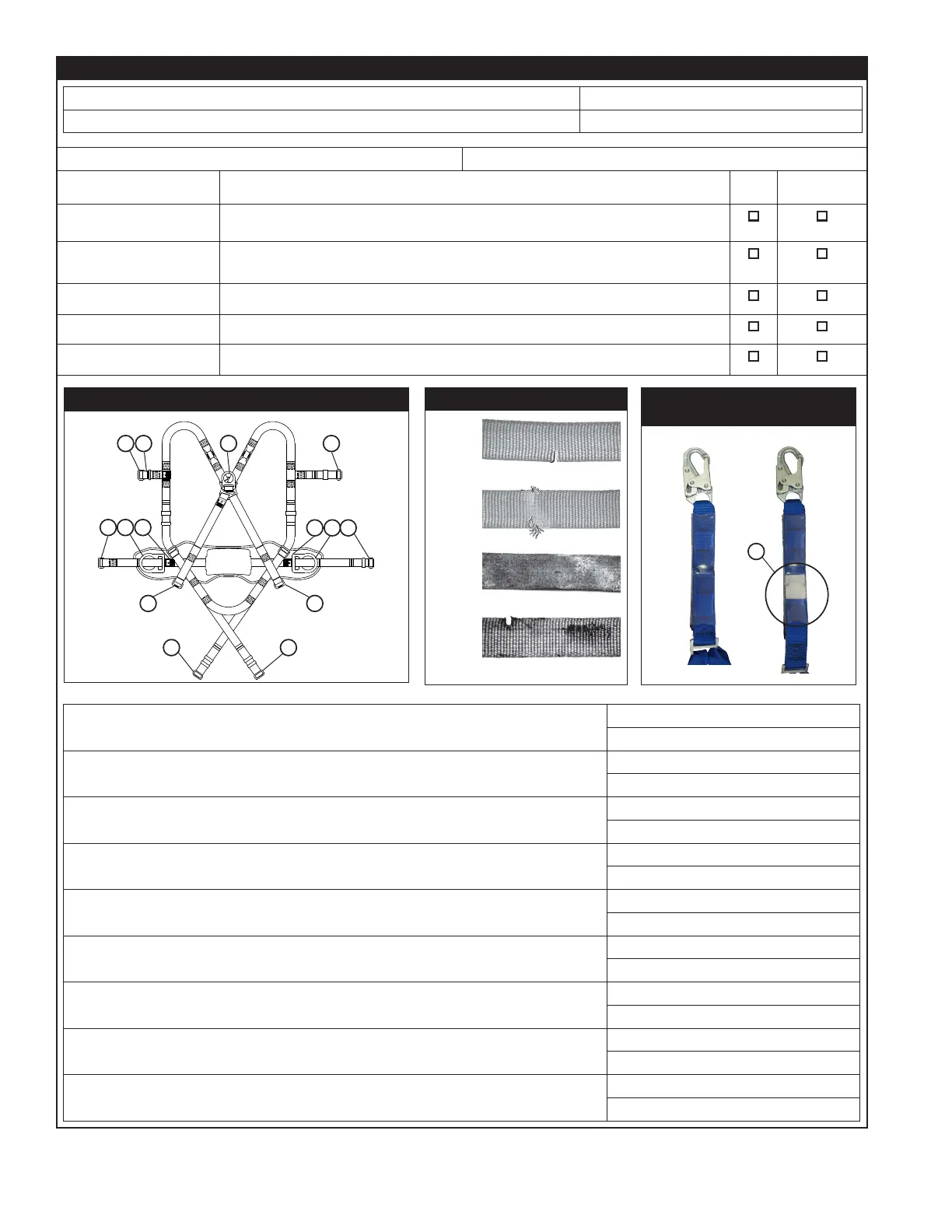

Harness Hardware

(Diagram 1)

Inspect harness hardware including buckles (1), adjusters (2), D-rings (3), etc. These items must not be

damaged, broken, or distorted, and must be free of sharp edges, burrs, cracks, worn parts, or corrosion.

Ensure buckles and adjusters work smoothly.

Webbing & Stitching

(Diagram 2)

Inspect webbing; material must be free of frayed, cut, or broken bers. Check for tears, abrasions, mold,

burns, or discoloration. Inspect stitching; Check for pulled or cut stitches. Broken stitches may be an

indication that the harness has been impact loaded and must be removed from service.

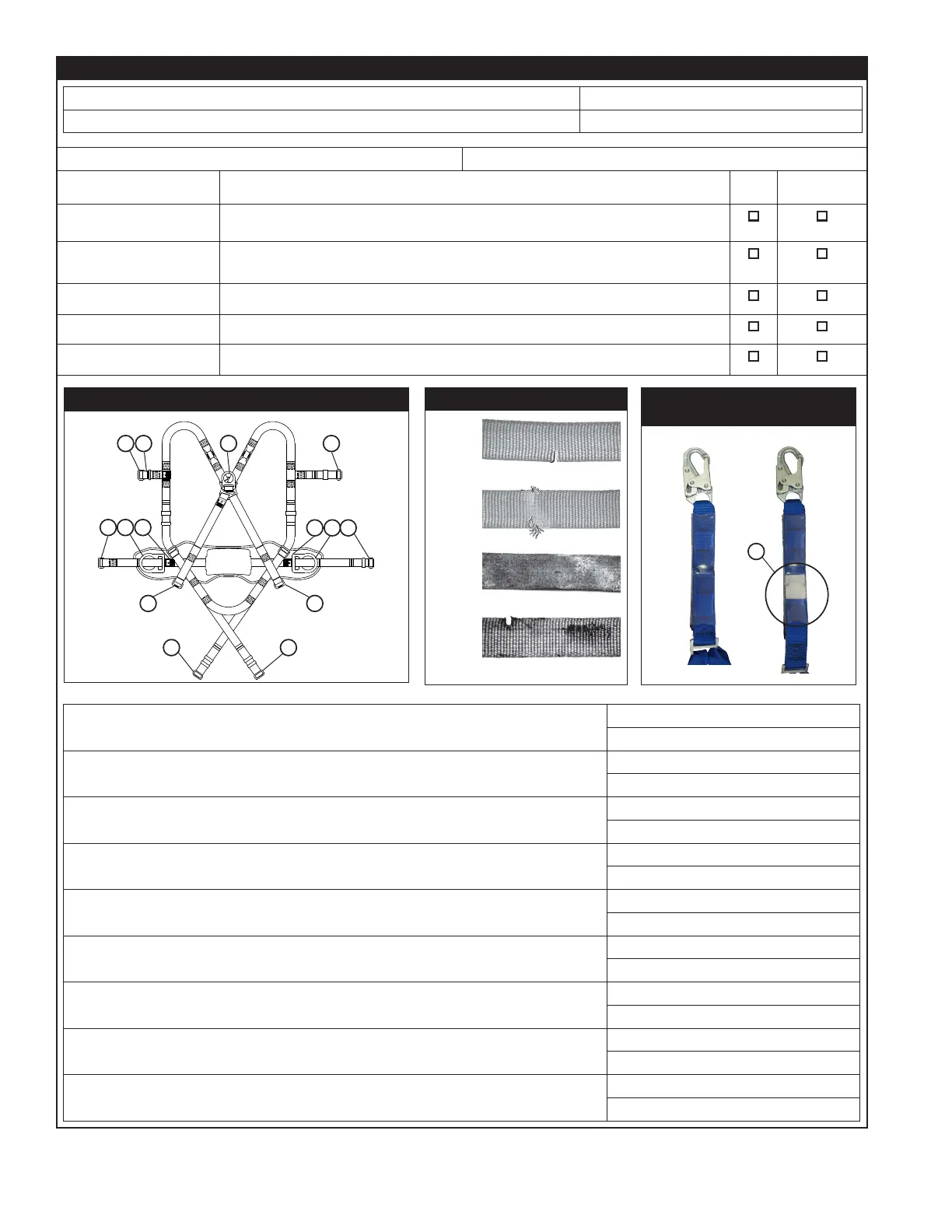

Integral Lanyard

(Diagram 3)

Inspect the Integral Lanyard (if applicable) has not been deployed. Deployed section (1).

Labels All labels should be present and fully legible. See Figure 11.

System & Subsystem

Components

Inspect each system component or subsystem according to the manufacturer’s instructions.

Diagram 1 – Hardware

Diagram 2 – Webbing

Cut

Frayed

Heavily

Soiled

Welding

Burns

Diagram 3 – Integral

Lanyard

Corrective Action/Maintenance: Approved By:

Date:

Corrective Action/Maintenance: Approved By:

Date:

Corrective Action/Maintenance: Approved By:

Date:

Corrective Action/Maintenance: Approved By:

Date:

Corrective Action/Maintenance: Approved By:

Date:

Corrective Action/Maintenance: Approved By:

Date:

Corrective Action/Maintenance: Approved By:

Date:

Corrective Action/Maintenance: Approved By:

Date:

Corrective Action/Maintenance: Approved By:

Date:

2

3

3

1 1

2

3

3

1

1

1 1

1 1

1

Loading...

Loading...