Commercial Electric Water Heater Use and Care Guide • 27

3

Remove the plasc element/

thermostat cover. Open the

lower access panel on the

water heater if replacing the lower

thermostat. Fold back the insulaon

and remove the plasc element/

thermostat cover.

4

Make sure the replacement

thermostat matches the

original thermostat.

5

Mark the wires with tape so

you’ll know how to put them

back on.

6

Disconnect the wires from the

bad thermostat and remove

the thermostat from the metal

mounng clip.

7

Install the new thermostat in

the metal mounng clip.

8

Make sure the new thermostat

ts snuggly against the tank.

You should NOT be able to slip

a business card between the

thermostat and the tank. If you can,

bend the thermostat mounng clip

unl the thermostat ts ghtly against

the tank.

9

Aach the wires following the

wiring diagram on the water

heater’s label. Make sure all

wire connecons are ght.

10

Replace the plasc element/

thermostat cover, insulaon,

and access panel.

11

Close the upper access panel

to the electrical juncon box.

12

Restore power to the water

heater. It may take two hours

for the tank to heat up.

Read and follow the operang and

annual maintenance instrucons

provided by the manufacturer of the

T&P Relief Valve (yellow label aached

to T&P Relief Valve). Minerals in the

water can form deposits that cause

the valve to sck or create blocked

passages, making the T&P Relief Valve

inoperave. Follow these guidelines:

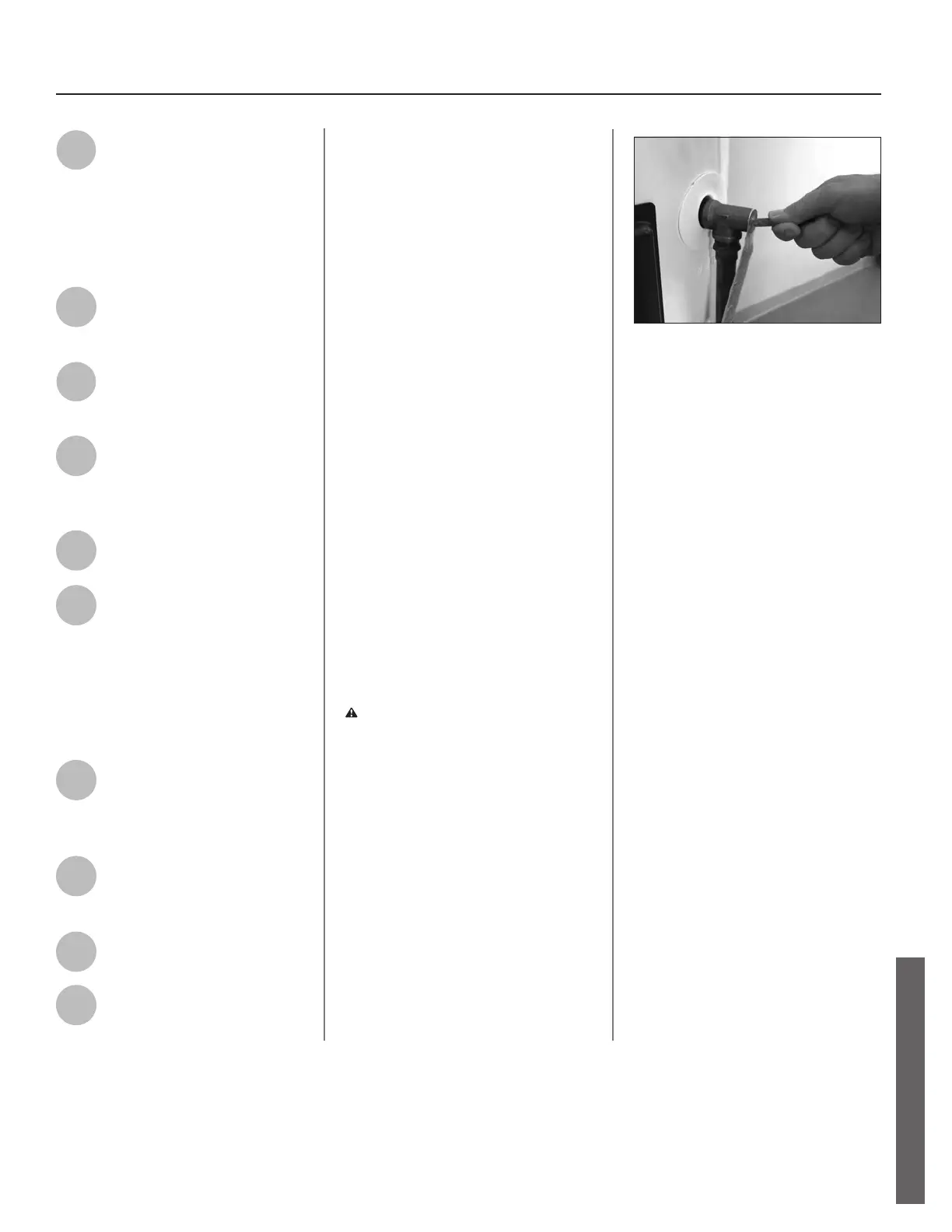

• At least annually, operate the

T&P Relief Valve manually to

ensure the waterways are clear

and the valve mechanism moves

freely (above). Before operang

the valve manually, check that

it will discharge in a place for

secure disposal. If water does not

ow freely from the end of the

discharge pipe, turn OFF the power

to the water heater. Call a qualied

person to determine the cause.

• Aer manually operang T&P

Relief Valve, remove any water in

the drain and wipe away any water

from the heater.

Figure 38 - T&P Relief Valve

• At least every ve years, have a

qualied person inspect the T&P

Relief Valve and discharge pipe.

Damage caused by corrosive water

condions, mineral deposits, or other

problems can only be determined

when a qualied person removes

and inspects the valve and its

components.

• Note that a dripping T&P Relief

Valve is usually caused by the water

pressure being too high or the lack of

a Thermal Expansion Tank. If your T&P

Relief Valve drips, see page 23.

MAINTENANCE

Loading...

Loading...