44

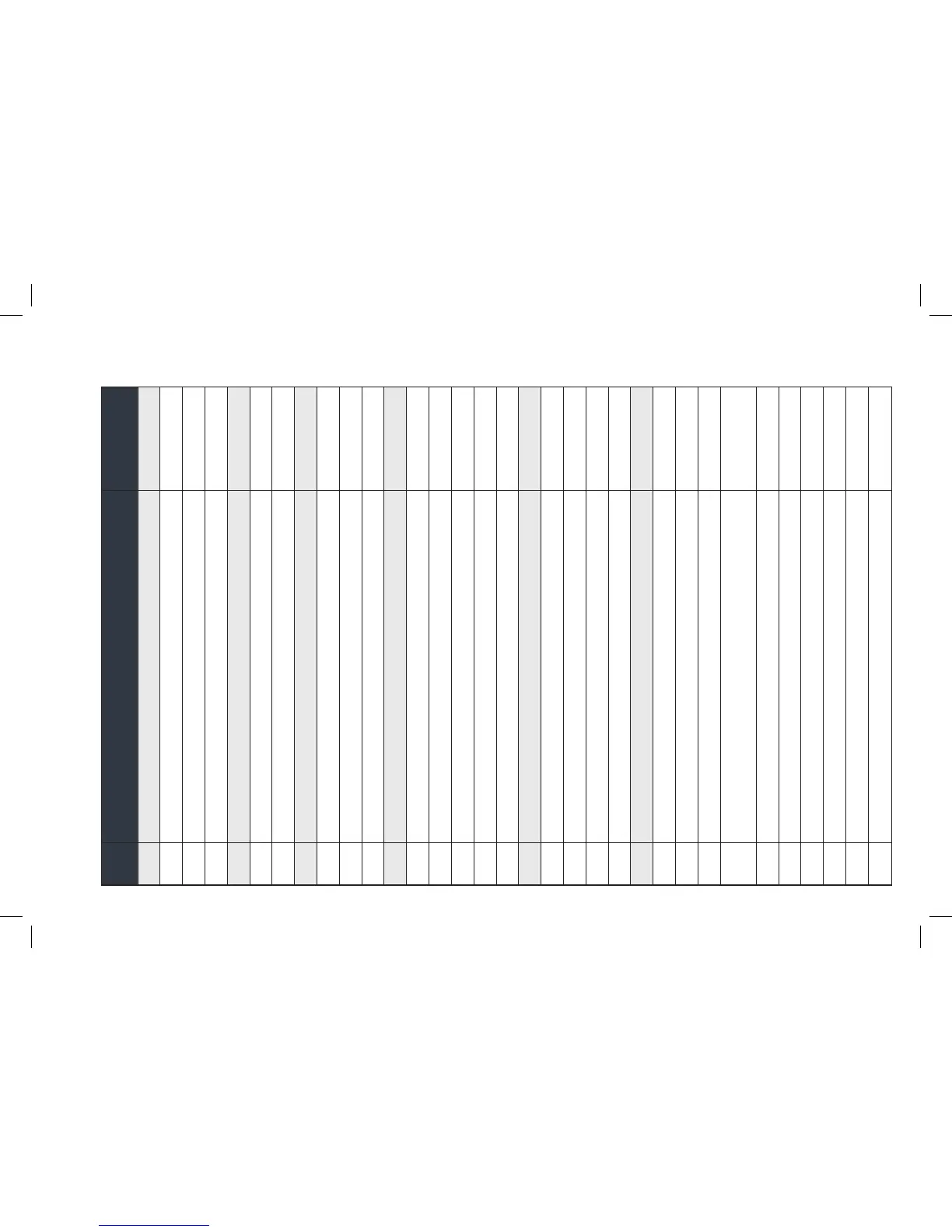

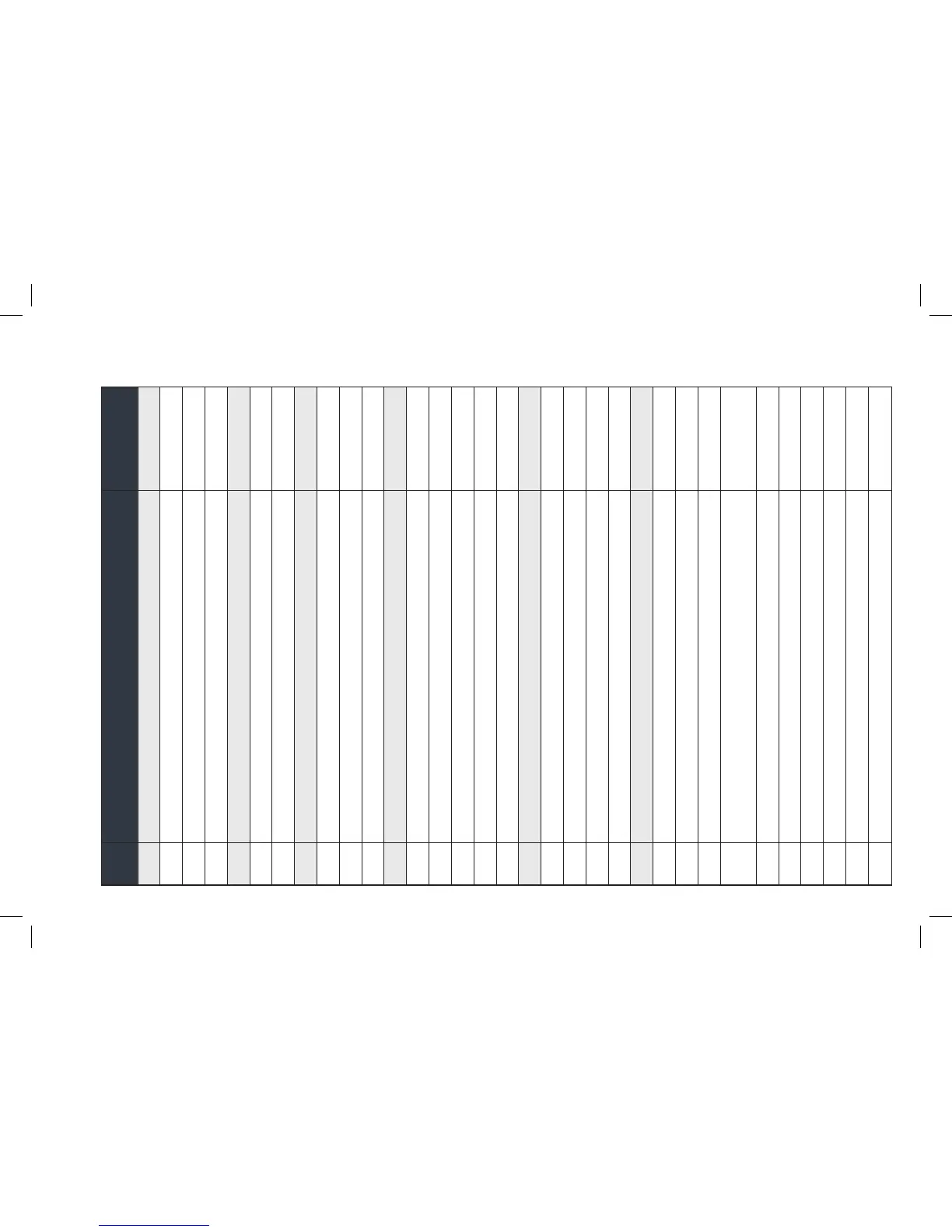

Maintenance schedule Assembly inspection every 2,500 km

No. Step

inspection

1 Assembly: Frame-Handlebars-Stem-Seat post-Saddle

Check the units for cracks and replace as necessary X

Screw inspection at handlebar/stem/saddle X

Clean & grease seat post down tube X

2 Front fork

Clean entire suspension fork, especially the sliding surfaces of the stanchions

X

Inspect the stanchions for damage and replace as necessary X

3 Rear wheel mount

Use air to clean TMM4 sensor without disassembly X

Check force fit & condition of the sensor plate

X

Check axle screw fitting for force fit X

4 Assembly: Crank - inside bearing pedal

Clean crank & pedal / grease pedal spindle X

Inspect the sprocket for damage and replace as necessary X

Check the crank and pedal attachment for force fit X

Check bottom bracket bearing for play and replace as necessary X

Detach bottom bracket bearing, clean & grease housing & screw thread X

5 Assembly: Chain-Cassette-Sprocket

Clean all parts. X

Check all screws for force fit X

Inspect units for wear and replace as necessary X

Clean & grease chain X

6 Assembly: Wheels-Rims-Tyres

Clean parts X

Check tyres for damage and profile depth X

Correct tyre inflation pressure X

Inspect front & rear wheel rim for lateral and radial run-out and correct as

necessary

X

Check spoke tension and correct as necessary X

Check the function & bearing play of the front wheel hub. X

Detach hub and clean and grease X

Loading...

Loading...