32

9. Routine inspections

Before proceeding with any operation,

always make sure that the springs of the

operating mechanism are discharged and

that the apparatus is in the open position.

9.1 General information

During normal service, the circuit-breakersaremaintenance-

free. Any interventions required basically depend on the se-

verityoftheserviceconditions,i.e.tovariousdifferentfactors

suchasthefrequencyoftheoperations,theinterruptedcurrent

values,therelativepowerfactorandtheinstallationsite.

Forprecautionaryreasons,aninspectionscheduleisgivenin

thetableinthefollowingsection,alongwiththefrequencywith

which the equipment must be checked.

Asfarasthislatterisconcerned,itisadvisabletocomplywith

thespecificationsinthetable,atleastduringthefirstinspec-

tion.

Optimal time limits for carrying out successive operations can

be established on the basis of the results obtained during the

routine inspections.

9.2 Inspection schedule

Inspection Frequency Criteria

1

Perform five mechani-

cal closing and opening

operations.

Once a year The circuit-breaker must

functionnormally,without

stopping in intermediate

positions

2

Visualinspectionofthe

poles (resin parts)

Once a year

or after

every5,000

operations

The resin parts must be free

fromanybuilt-updust,dirt,

cracks,dischargesortraces

of surface discharges

3

Visualinspectionofthe

operating mechanism

and transmission

Once a year

or after

every5,000

operations

The elements must not be

deformed in any way.

Screws,nuts,bolts,etc.,

must be tight

4

Measurement of the

insulation resistance

Every 5

years or after

every5,000

operations

See sect. 8.1 point 1

5

Checking interlock

operation

Every 5

years or after

every5,000

operations

The interlocks provided must

function correctly

Warning!

Contact the ABB Assistance Service and have the circuit-

breakercompletelyoverhauledafter10,000operationsorafter

10 years.

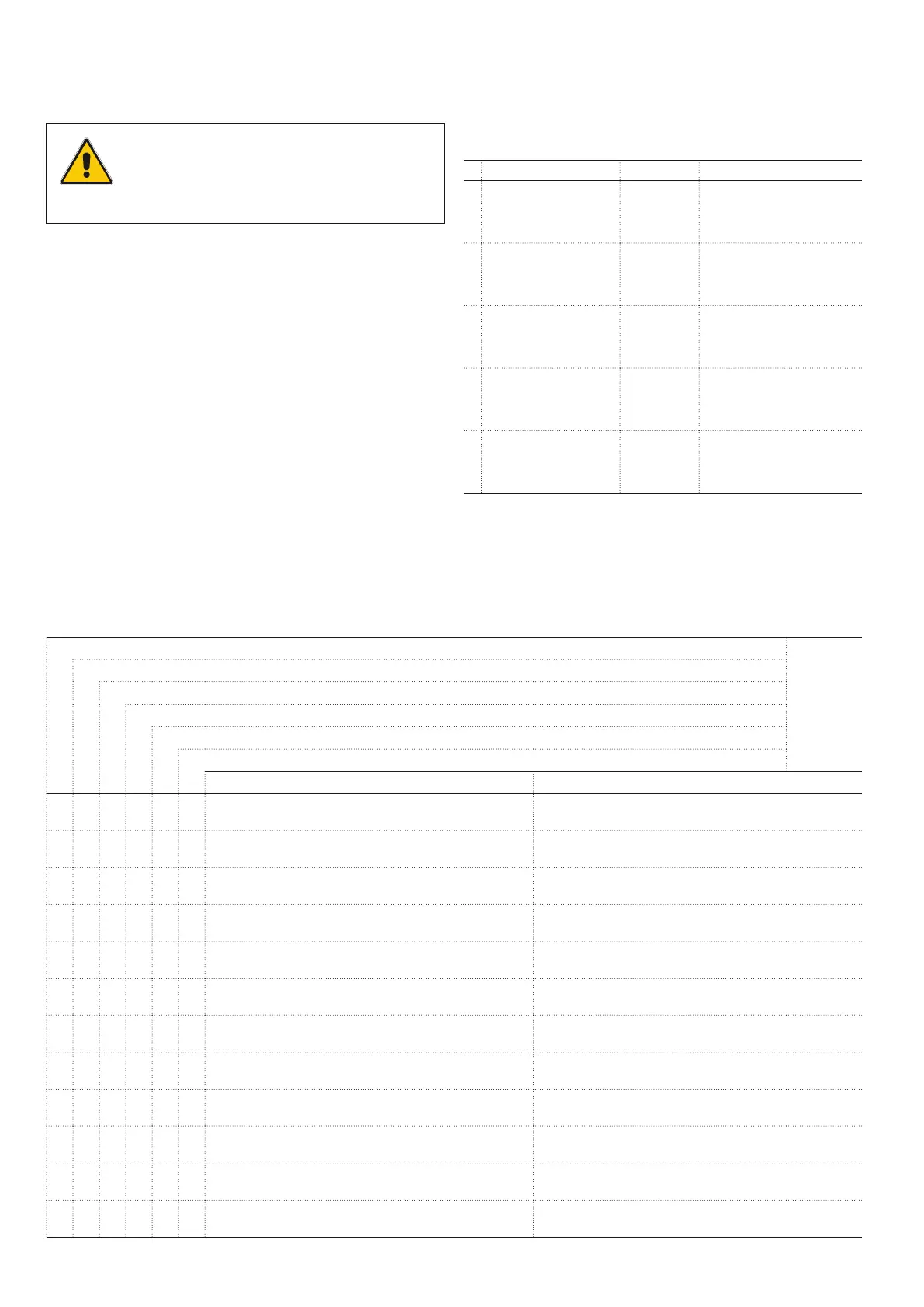

9.3 Troubleshooting

The shunt opening and/or shunt closing release remains energized

Faults

The shunt opening and/or shunt closing undervoltage releases are insufficiently energized

Releasecoilsinterruptedorburnt,gearmotorwindinginerrupted

The circuit-breaker fails to open

The circuit-breaker fails to close

Flashovers

Possible causes Inspections and remedies

•

Operating or accept contacts locked closed

Check the condition of the contacts in series with the

release

• • •

Supply votage of the auxiliary circuits too low

Measure the voltage: it must not be less than 85% of the

rated voltage

• •

Supply voltage different from the value indicated on the

nameplate for these releases

Check the voltage indicated on the nameplate of the

releases

• • • • •

Faulty switching circuit

Checktheconnections,fuses,interlocks,protection

switches and accept contacts

• • •

Loose wire clamping screws Make sure that the wire clamping screws are tight

• • • • •

Incorrect electrical connections in the power supply circuit Check the connections with the relative functional diagram

• • •

Release coils interrupted Replace the coils

•

Conductive dust on the insulating parts

Clean carefully. Check the insulation resistance with a 2500

VMegger(sect.8.1.)

• • •

Operating mechanism locked

Operate in the manual mode. Contact ABB if the fault

persists

•

Key not inserted in the key lock of the operating mechanism Insert and turn the key

•

Undervoltage release not energized Check the relative supply circuit

•

Shunt opening release remains energized

Check the supply circuit and the relative contact in series

with the release coil

Loading...

Loading...