Chapter 4 – Electrical Installation

Installation and Start-up Guide for NBRA-6xx 4-11

ACS 600 Connection Ensure that the UDC+ and UDC– busses of the chopper are properly

connected to the corresponding terminals of the ACS 600 (see Chapter

3 – Voltage Selection and Mechanical Installation).

Resistor Cable

Connection

Connections at the braking resistor:

(For terminal tightening torques, consult resistor documentation.)

• Twist the screen wires together and connect them to the earthing

terminal, along with conductor no. 3 (if present).

• Crimp cable lugs of appropriate size onto conductors 1 and 2.

• Connect conductor no. 1 to the R+ terminal.

• Connect conductor no. 2 to the R– terminal.

Connections at the braking chopper:

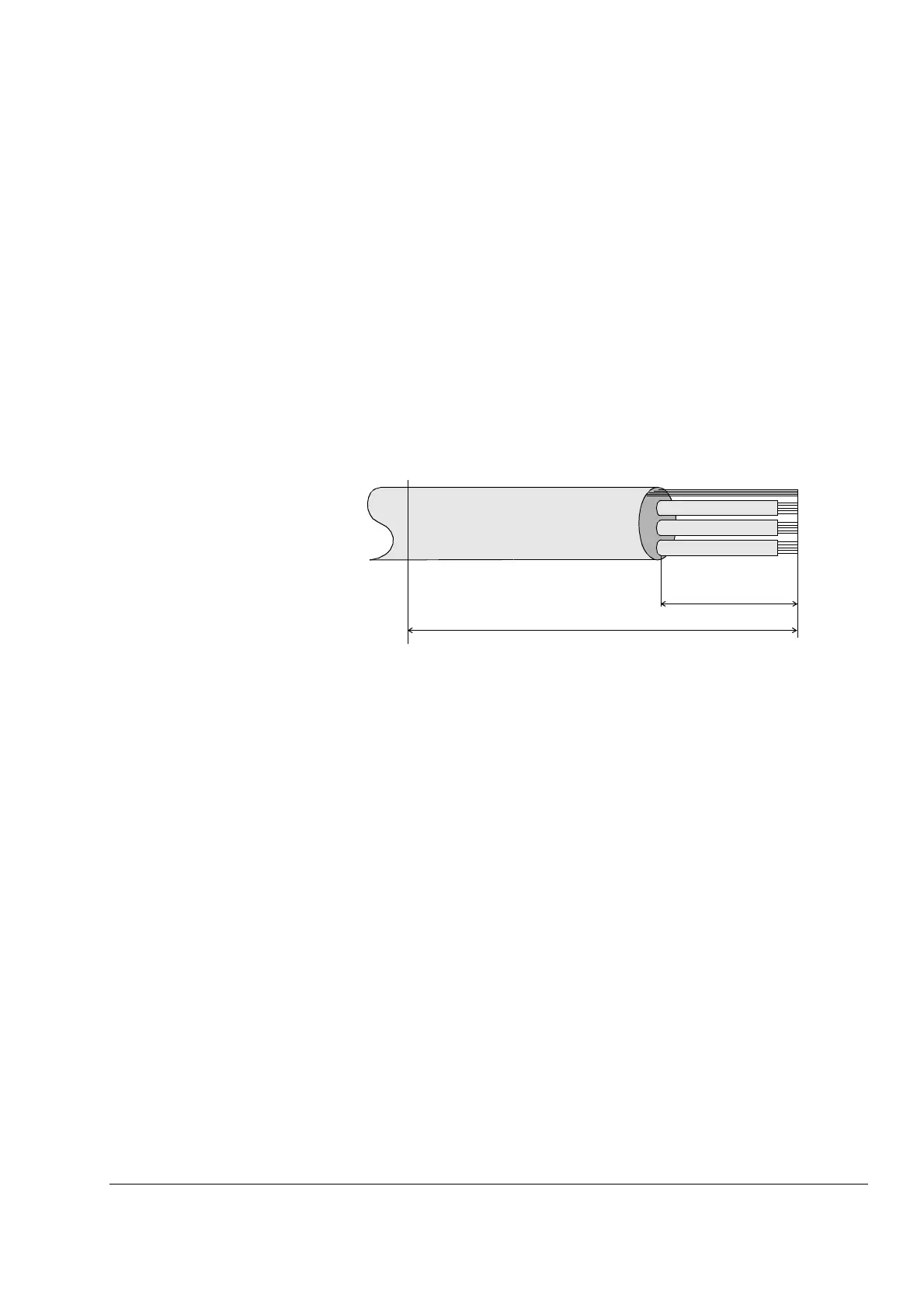

Figure 4-7 Resistor cable stripping diagram (braking chopper end).

All lengths are approximate and may vary according to the

cable lugs used.

• Cut and strip the cable as shown in Figure 4-7 above.

• Lead the cable through the cable entry into the converter unit.

• Slip the copper sleeve (inserted into the earthing clamp at the

factory) onto the outermost insulation of the cable so that insulation

and sleeve edges are aligned (see Figure 4-6).

• Bend the screen wires evenly backwards onto the copper sleeve.

• Unfasten the screen earthing clamp and slip it onto the screen wires

at the copper sleeve. Replace the clamp and tighten the fastening

screw to 3 Nm.

• Twist the screen wires together and connect to the earthing clamp

on the chopper as shown in Figure 4-6. Tighten the screws to 3 Nm.

• Connect conductor no. 3 (if present) to the earthing clamp on the

chopper (below the screen earthing clamp) as shown in Figure 4-6.

Tighten the screws to 3 Nm.

70 mm

190 mm

Gland Plate

Screen

1

3

2

Loading...

Loading...