12 RHD250 to 4000 (Contrac) ELECTRICAL ROTARY ACTUATOR | SEI/RHD250/4000-EN REV. A

… 4 Maintenance

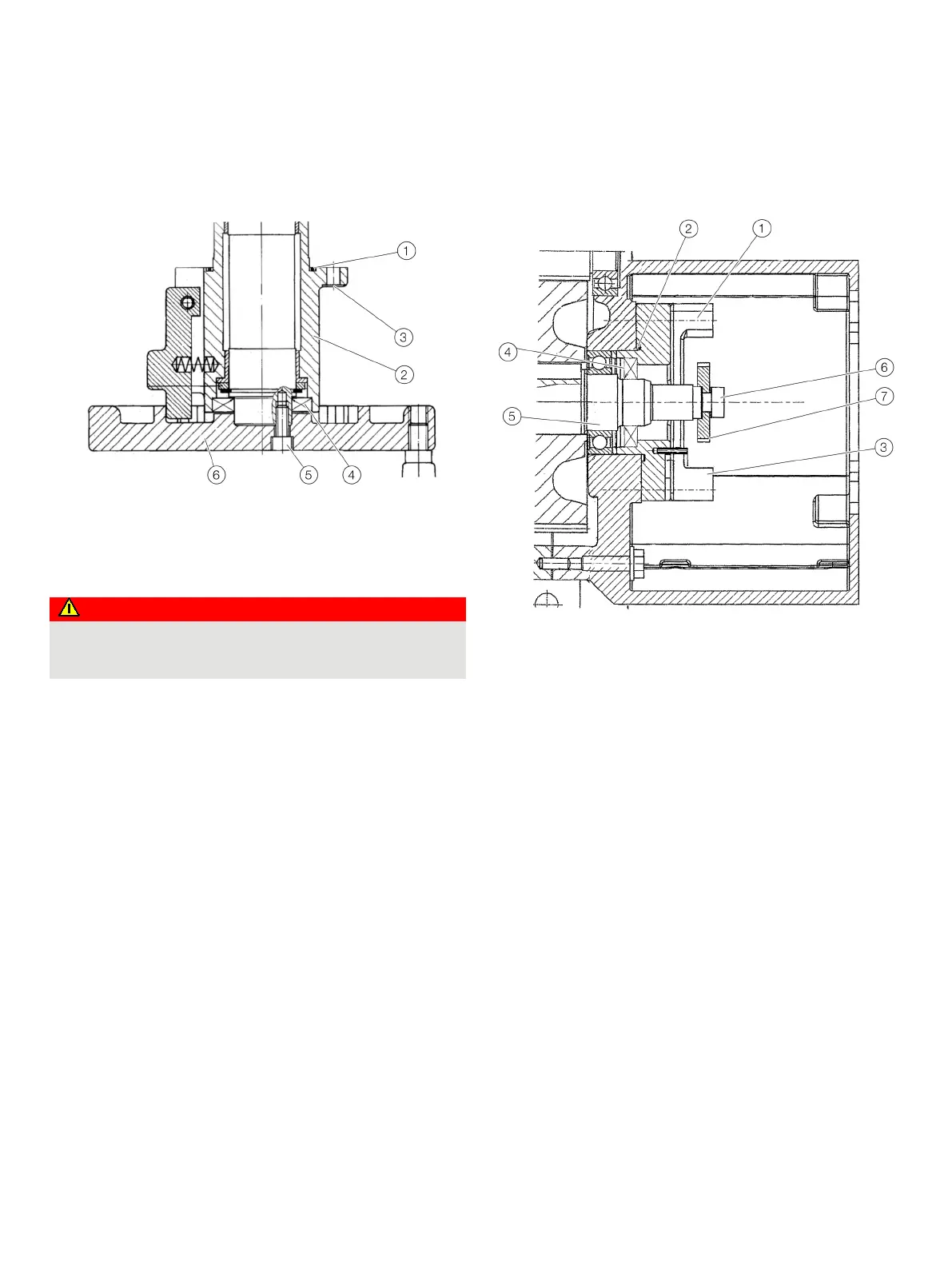

Sealing ring of hand wheel drive / hand

wheel shaft

O-ring

Housing flange

Flange screws

Sealing ring

Screws

Hand wheel

Figure 9: Handwheel

Danger to life due to unexpected movement of the actuator!

Restoring process forces may move the actuator when you

In order to change the handwheel O-ring

1 of the drive proceed

as follows:

1. Make sure that the oil level is below the O-ring

1.

2. Drain the oil if necessary (see Oil change on page 6 for

details).

3. Turn flange screws

3 out.

4. Pull entire hand wheel drive assembly out of the gearing

engagement.

5. Replace the O-ring

1.

6. If additionally the shaft sealing ring

4 needs to be replaced,

turn the wheel fastening screws

5 out and put the hand

wheel

6 aside.

7. Take the shaft sealing ring

4 out.

8. Grease the new the shaft sealing ring

4 slightly with oil and

put it into the groove; consider the exemplary hints and

illustration of Sealing ring of output drive shaft on page 11.

9. Fasten the hand wheel

6 and re-install the entire assembly;

tightening torque for the screws

3 = 20 Nm (15 ft-lbs).

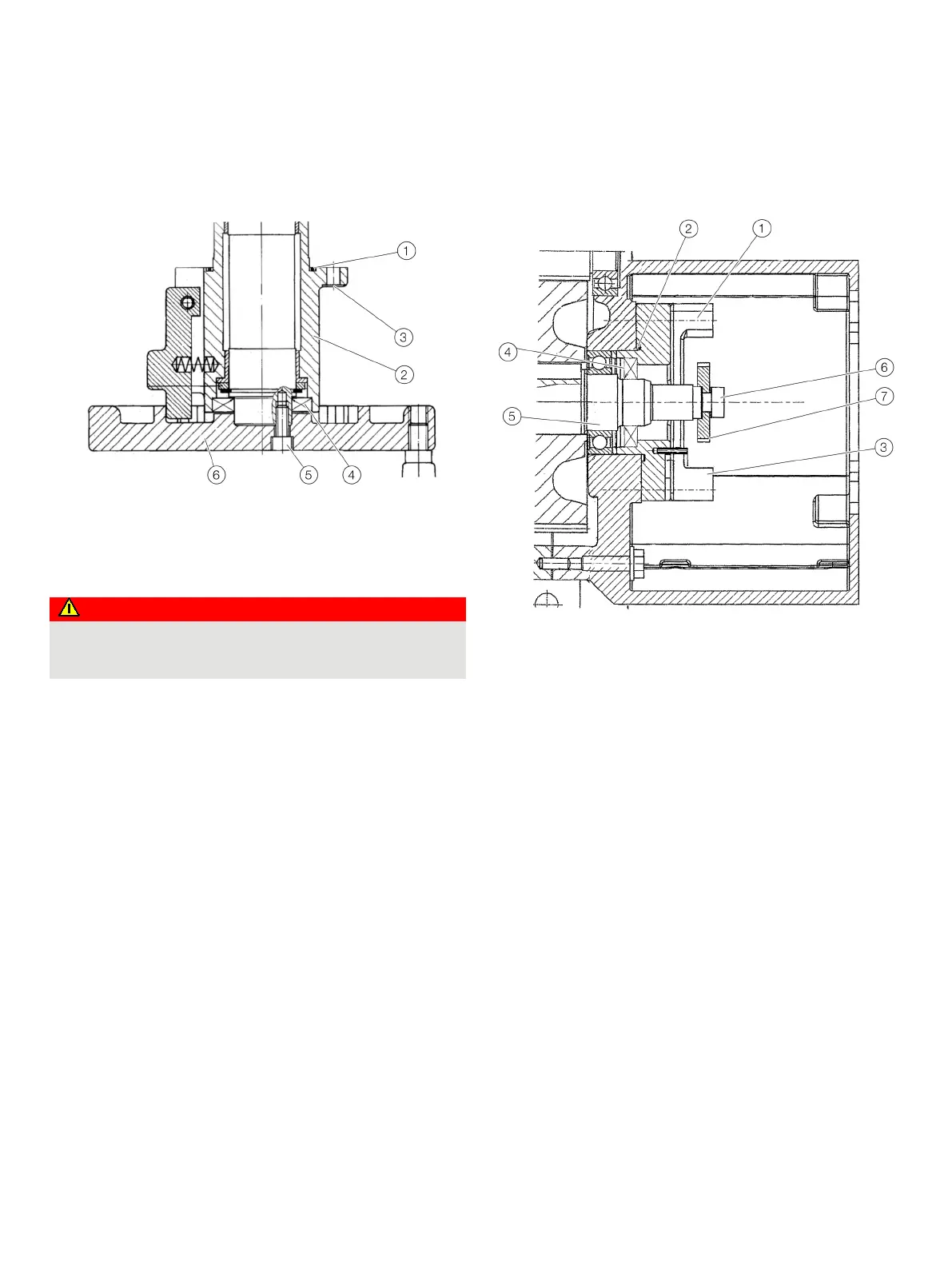

Sealing of the position sensor drive

RHD250...RHD800

Flange fastening screw

O-ring

Flange

Sealing ring

Shaft

Hexagon screw

Pinion

Figure 10: Position sensor drive

In order to change the O-ring

2 and the sealing ring 4, firstly

remove the position sensor Dismounting on page 27 and

proceed as follows:

1. Make sure that the oil level is below the O-ring

2.

2. Drain the oil if necessary (Mounting position on page 6 for

details).

3. Loosen the hexagon screw

6 and pull apart the pinion 7.

4. Undo flange fastening screws

1.

5. Pull the flange

3 with sealing ring 4 carefully from the

shaft

5 and put it aside.

6. Replace the O-ring

2.

7. Pull the old sealing ring

4 out of the groove.

8. Grease the new sealing ring slightly with oil and put it in.

9. Clean the shaft and the contact surfaces of the flange.

10. Carefully push the flange

3 with O-ring 2 and sealing

ring

4 on the shaft; take care that the shaft end does not

damage the sealing ring.

11. fasten the flange

3 and thighten the screws 1 crosswise

with 8.3 Nm (6.12 ft-lbs).

12. fasten the pinion

7 and tighten the hexagon screw 6 with

42 Nm (31 ft-lbs).

Loading...

Loading...