14

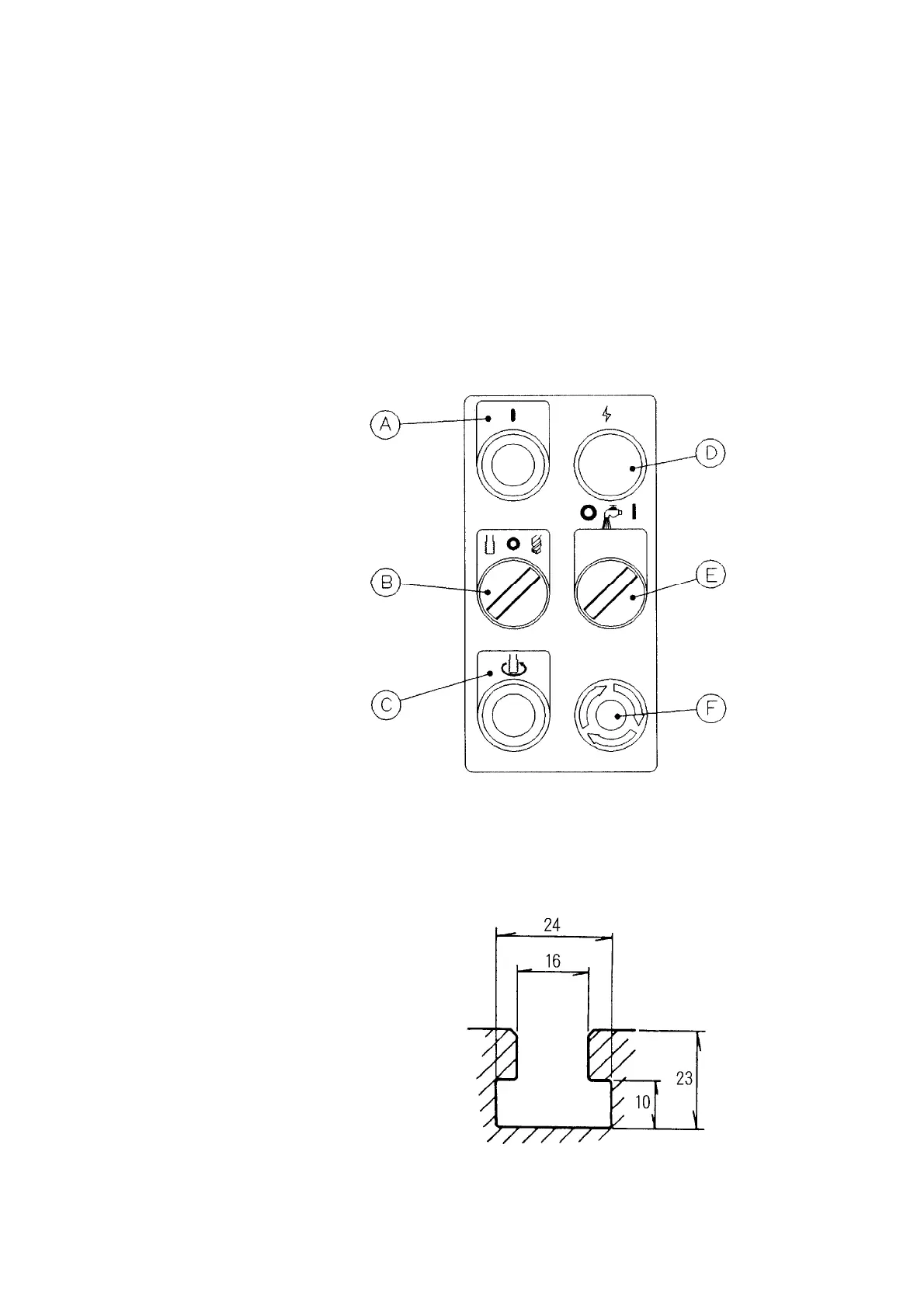

(4) Turn the handle downwards, when the spindle leaving 1

st

limit switch (hear the sound), push the

start button A, spindle will begin to run and prepare for tapping.

(5) When reaching the bottom of your tapping depth, the spindle will reverse automatically. Release

the handle, the spindle will return upwards to its original position, then stop running.

(6) CAUTION: When in emergency or tapping drill was stuck in the tapping hole. Punch the

EMERGENCY switch F to stop the spindle running. Use button C for instant reverse of the

spindle.

(7) After finishing your tapping work, remember to turn the select switch B to “NEUTRAL”

position.

(8) E is coolant pump switch.

(9) D is power indicator.

Fig. 3

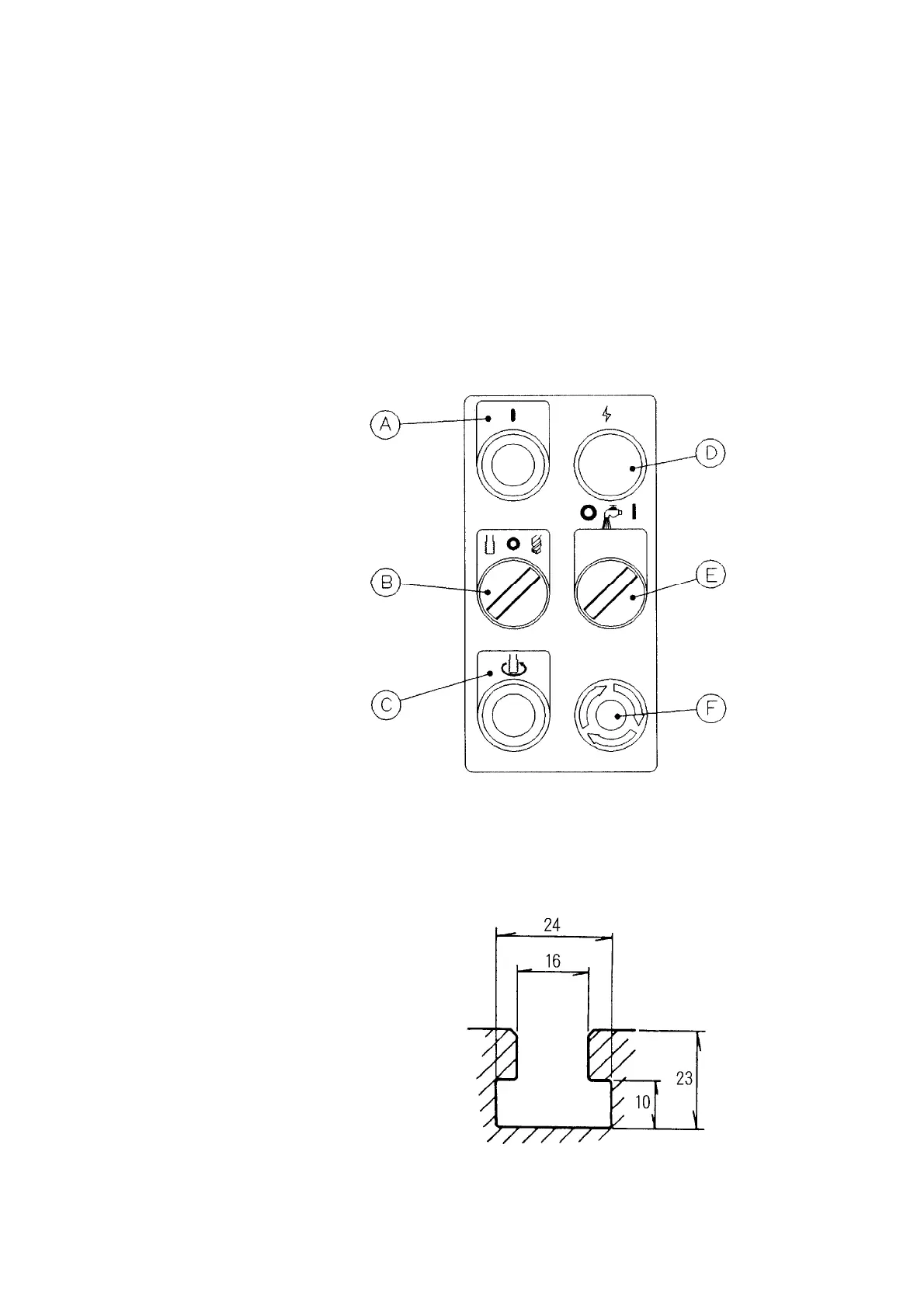

14. SPECIFICATION OF T-SOLT

The size of T-Solt on table as Fig 6:

RF-46BSF Fig. 6

Loading...

Loading...