Commissioning

The procedure detailed under periodic maintenance

should be followed

Periodic maintenance

As detailed in BS 9999:2008

1. For dampers this is at least once per year for

units with spring operation.

2. Units operating in dust laden atmospheres,

should be checked more often to suit the severity

of the conditions

3. Units associated with systems may be required

to be checked, as part of the system, as often

as once per week or month to ensure ongoing

condence in the life safety system. This may

be seen as analogous to re alarm systems.

Procedure

1. The units should be carefully inspected and

cleaned of dust and debris

2. The units should then be lubricated with a light

oil, by wiping this over all the surfaces

3. The mode should be operated to ensure that it

is moving the blades from open to closed and the

reverse.

4. If the end switches (in the mode) are being used,

it should be checked that they are actually indicating

that the blades are open or closed. This is done

by running a cycle and checking both the blades

(open and closed) and the indication that the

micro switches are feeding back to.

Actuator tting (If required)

The control mode/actuator should be tted in

accordance with the documentation supplied with it.

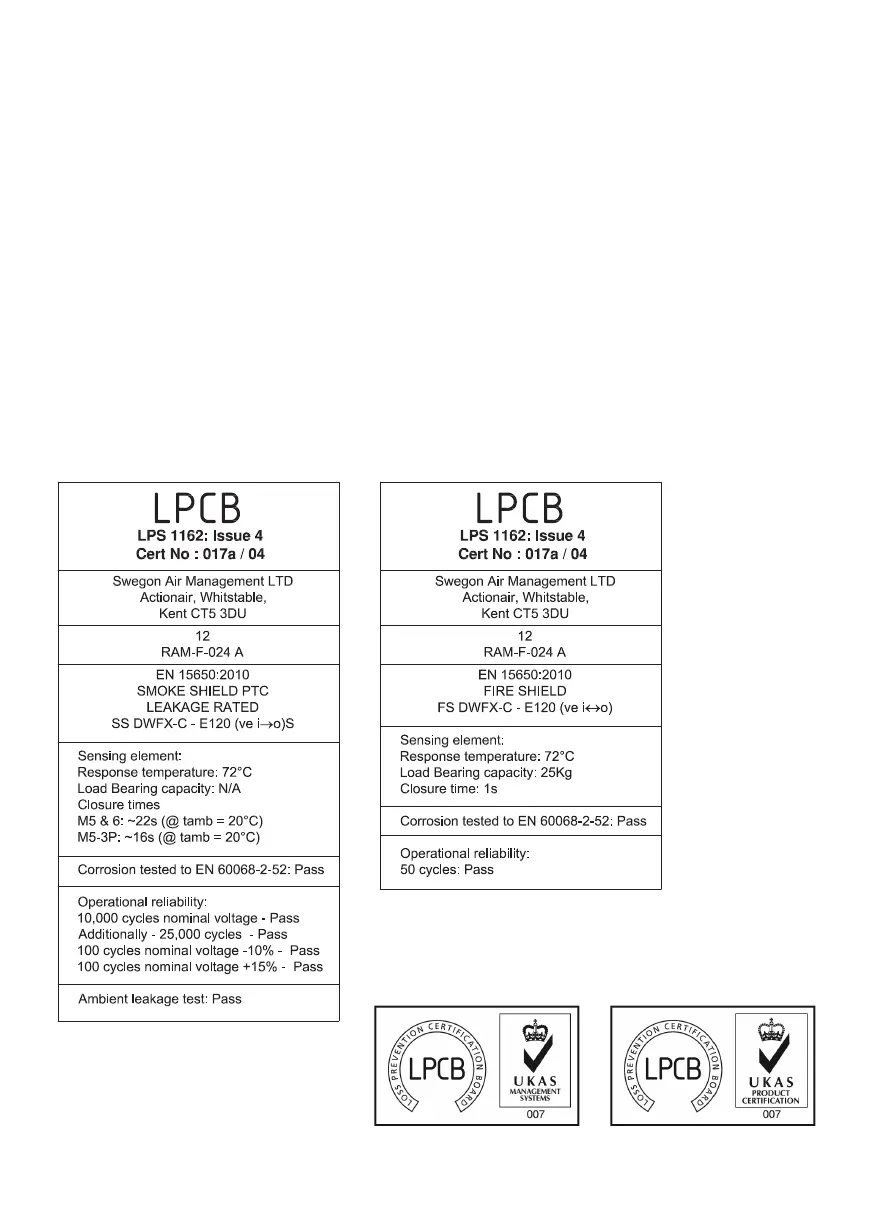

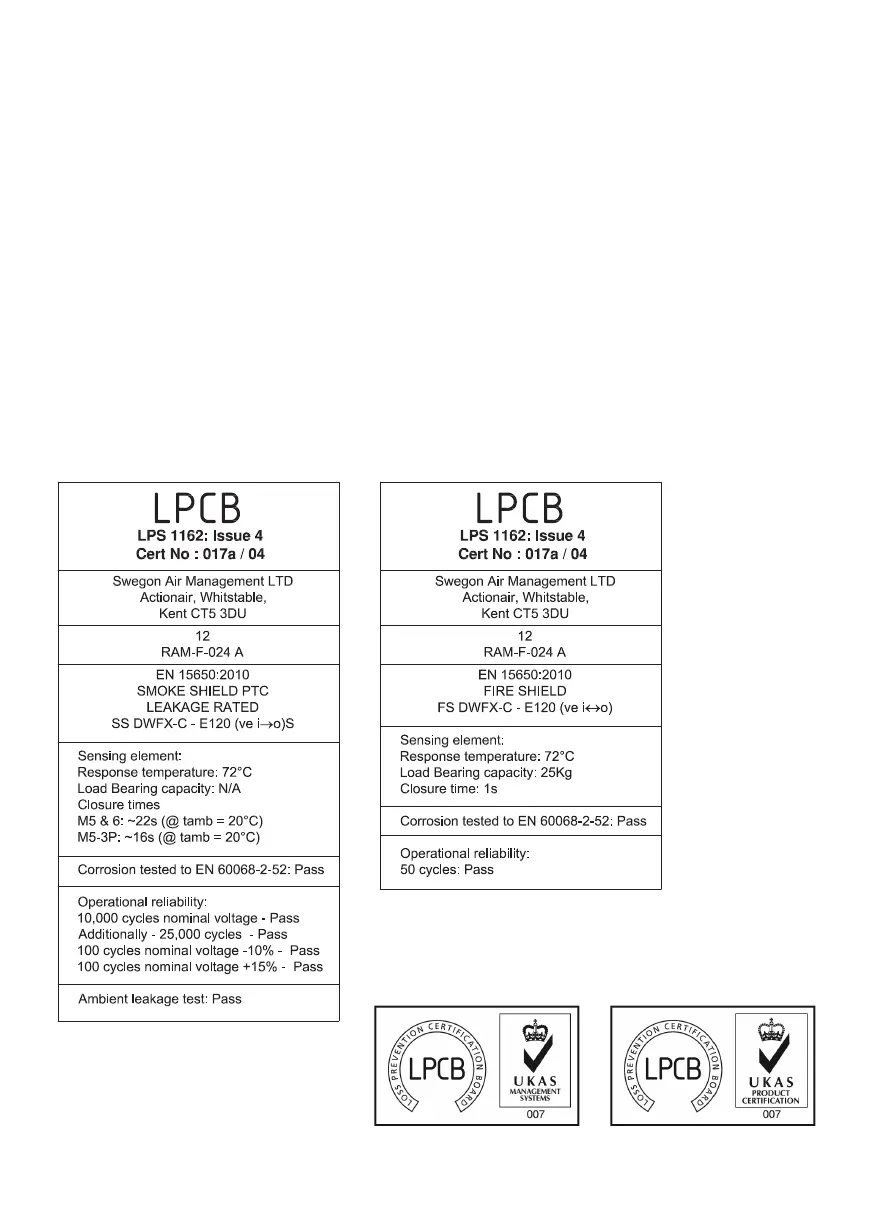

Assessed to ISO 9001:2008

LPCB Cert No. 17

LPS1162 Cert No. 017a

Loading...

Loading...