with the mains with particular caution!

• Make sure that the available voltage is not higher than the device’s stated voltage.

• Make sure that the power-cord is never crimped or damaged by sharp edges. Check the device and the

power-cord from time to time.

• Always disconnect the power, when the device is not in use or before cleaning it.

• Keep away children!

INSTALLATION & PRECAUTIONS:

• THE MAXIMUM WEIGHT THAT THE MIRROR BALL MOTOR CAN HOLD MUST NOT EXCEED 22LBS.

• This product was designed for indoor use only.

• Make sure that the area located below the installation is clear when rigging, derigging or servicing the x-

ture.

• Please save and use the original packaging for transportation.

• If this mirror ball motor is operated in any way dierent to the way described in this manual, the product

may suer damages and the guarantee becomes void. Furthermore, any other operation may lead to dangers

like short-circuits, burns, electric shock, crash etc.

• Please consider the EN 60598 norms during the installation!

• The installation must only be carried out by a qualied electrician or an authorized dealer!

• The installation sturcture of the mirror ball has to be built and constructed in a way that it can hold 5 times

the weight for 1 hour without any causing any deformation of the installation structure.

• The installation must always be secured with a secondary safety attachment, e.g. an appropriate catch net.

This secondary safety attachment must be used in a way that no part of the installation can fall down if the

main attachment fails, e.g. a safety cable.

• Rigging/installing, derigging or servicing the xture over any high working places, general public, and other

dangerous areas is forbidden.

• The operator has to make sure that safety-relation and machine-technical installations are approved by an

expert before operating for the rst time and after any changes in installation.

• The operator should make sure that safety-relation and machine-technical installations are approved by an

expert after every four years.

• The operator should make sure that safety-relation and machine-technical installations are approved by a

skilled person once a year.

• The mirror ball should be installed outside areas where persons may walk by or be seated.

• The chosen installation spot must be in a way that the motor can be installed in an absolutely horizontal

position.

• The motor and the mirror ball must be installed out of the reach of people.

• If the motor shall be lowered from the ceiling or high joists, professional trussing systems have to be used.

The motor must never be installed in a way that it can swing freely in the room.

Caution: Mirror balls will cause severe injury if it happens to come crashing down! If you have any doubts

concerning the safety of a possible installation, do NOT install the motor!

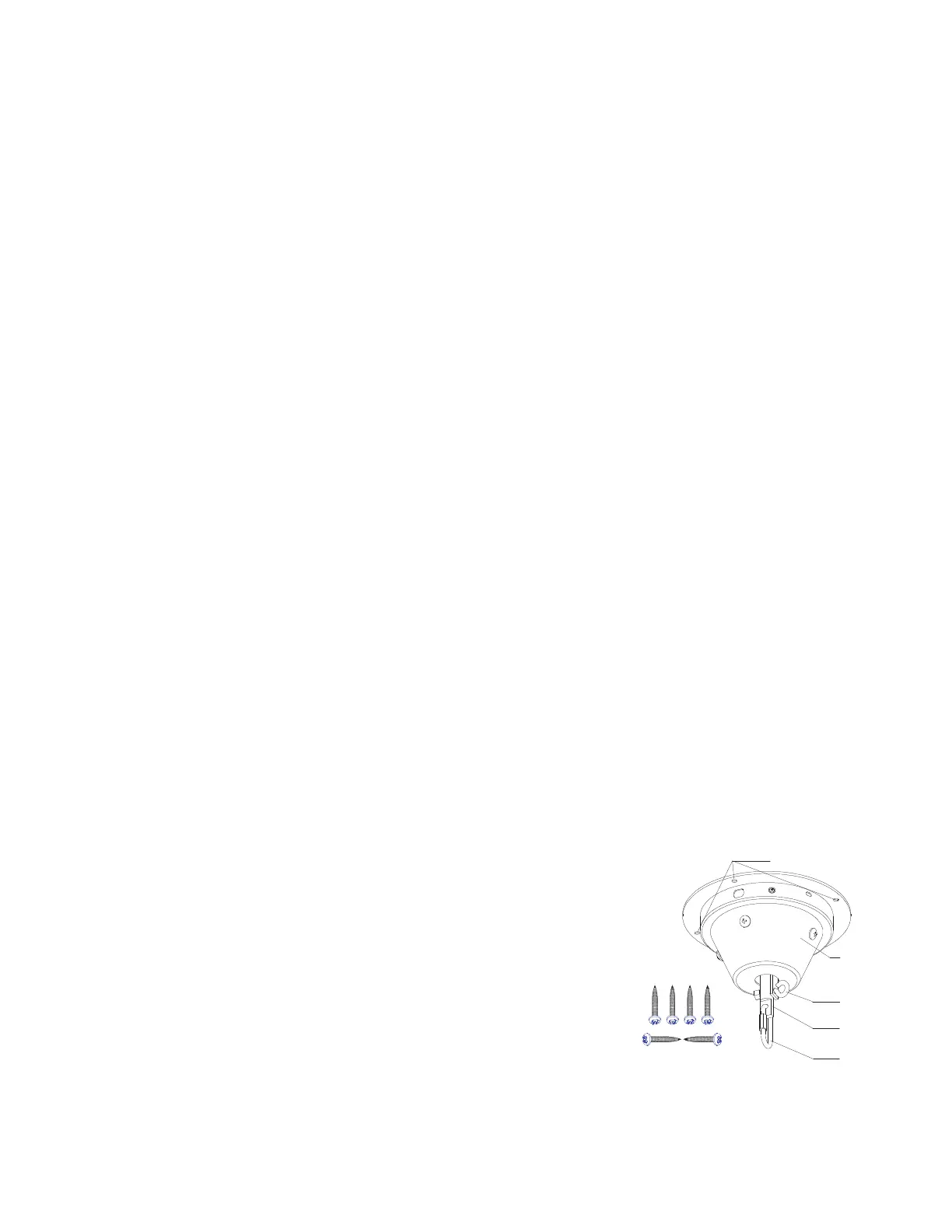

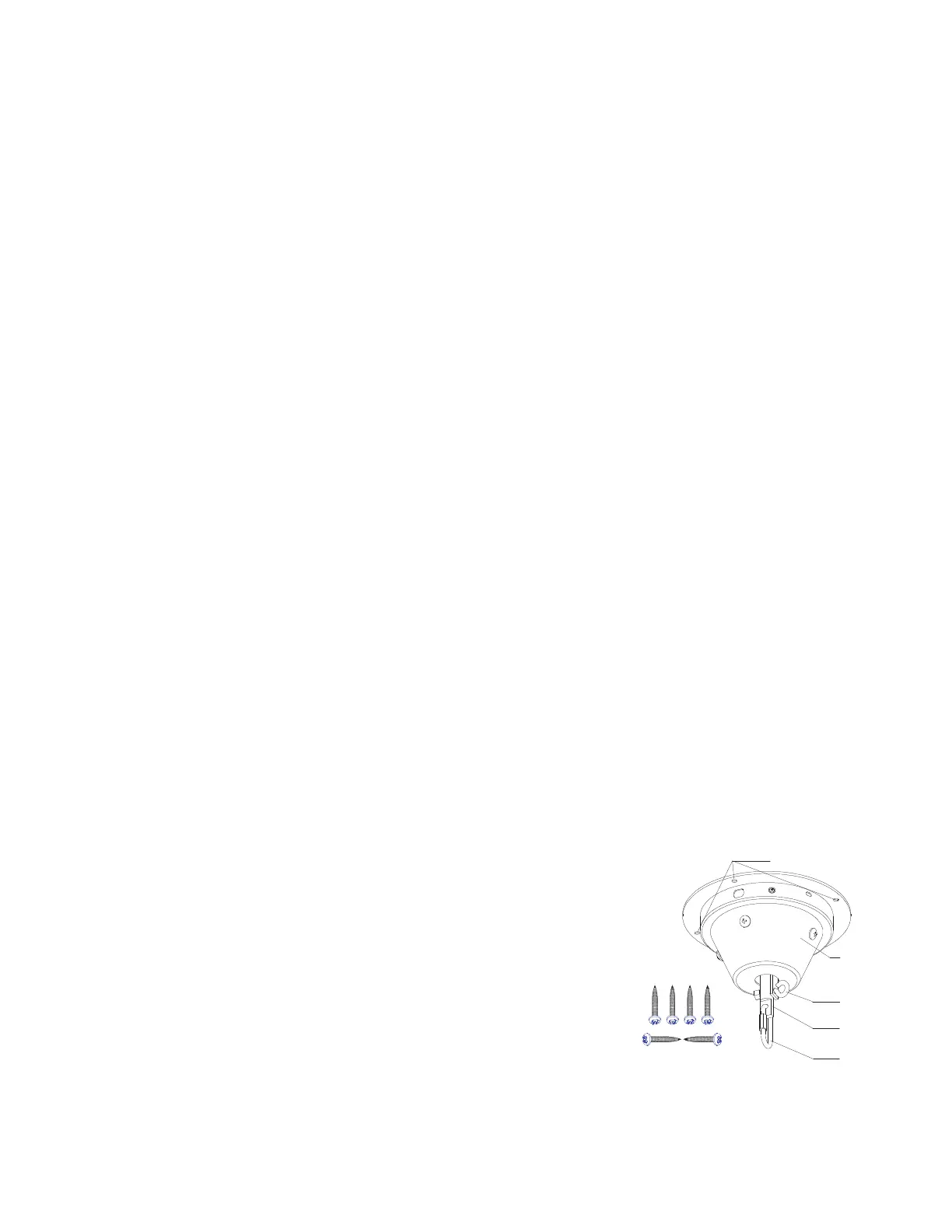

• BEFORE RIGGING MAKE SURE THAT THE INSTALLATION STRUC-

TRUE IS ABLE TO HOLD A MINIMUM OF 110LBS. POINT LOAD.

• Please install the mirror ball motor using all 4-xation holes.

• Only use the appropriate screws and make sure that the screws are prop-

erly connected with the ground.

• If the unit will be directly connected with the local power supply network,

a disconnection switch with a minimum opening of 3 mm at every pole has

to be included in the permanent electrical installation.

• The mirror ball has to be connected via an appropriate installation with

the motor. We recommend using Chain for Mirror balls up to 50 cm certi-

ed, or Chain for Mirror ball up to 100 cm certied.

Caution: The installation material must never include abrading material e.g. steel cables in order to

avoid material wearing.

• The length of the chain must never exceed 100 cm.

SCREW-ON

CHAIN LINK

MOTOR AXLE

ATTACHMENT

EYELET

HOUSING

Fixation Screw

Fixation holes

Loading...

Loading...