General

1. Please read

the

present

instructions carefully

and

observe

the

re-

commendations.

2.

The

following

text

applies

only

to

the

basic

operation

of

the

Adler

30.

If

operation

of

the

sub-classes differs

from

that

of

the

basic design, please see

the

attached

supplementary

instructions.

3.

The

different

languages have

been

marked

on

the

sheet

margin

by

the

respective letters:

D German

E English

F

French

S Spanish

Please

unfold

the

table

of

illustrations

at

the

end

to

the

right

so

that

you

can

see simultaneously

the

text

and

the

illustrations.

4.

In

order

to

extend

the

life

of

the

machine

the

maximum

sewing

speed

should

be

reduced in following cases:

During

the

running-in period

In

the

case

of

thick

material

When in

continuous

use

When using long stitches

When difficult

operations

are

involved

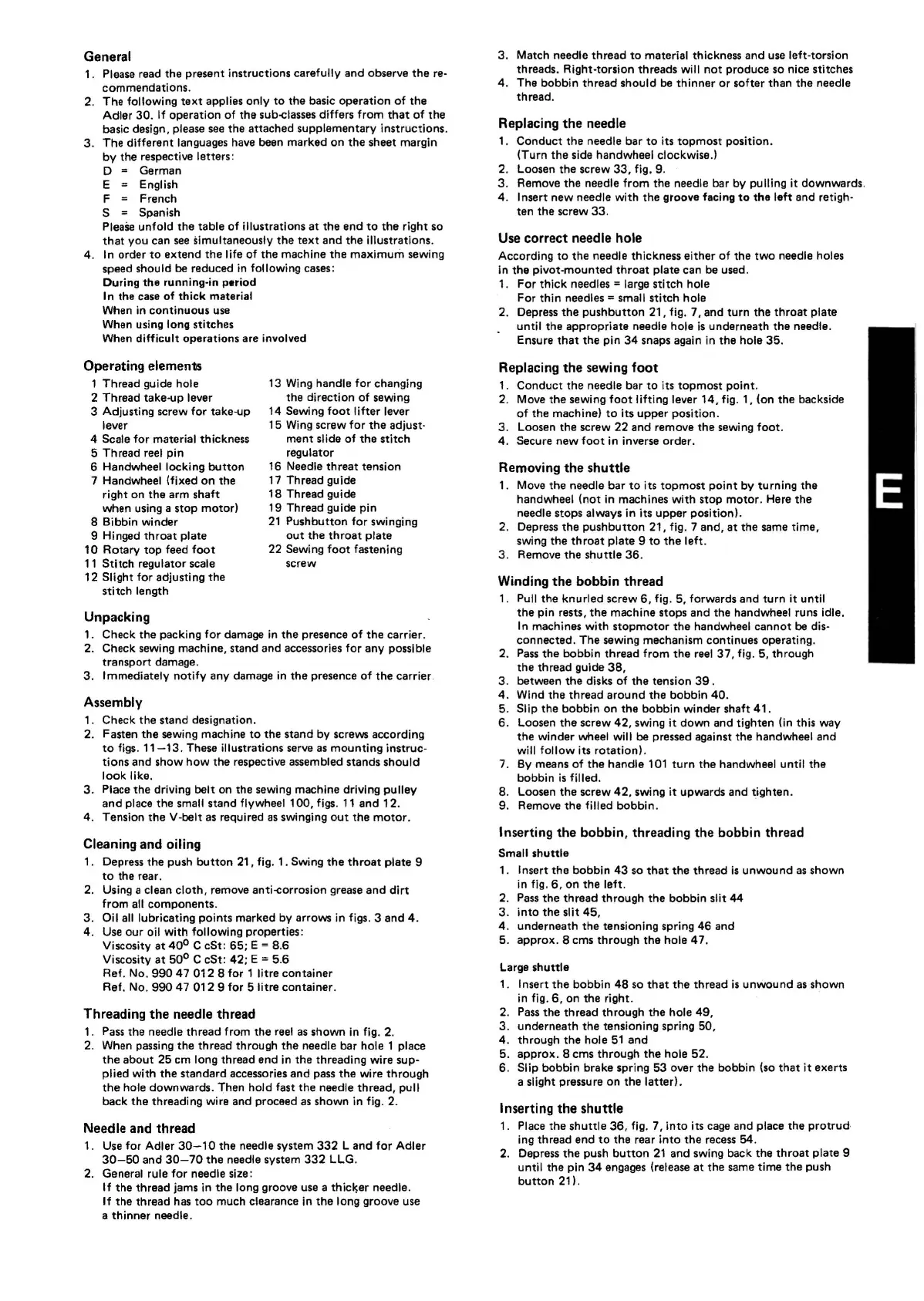

Operating elements

1

Thread

guide hole

2

Thread

take-up lever

3 Adjusting screw

for

take-up

lever

4 Scale

for

material thickness

5

Thread

reel pin

6 Handwheel locking

button

7 Handwheel (fixed

on

the

right

on

the

arm

shaft

when using a

stop

motor)

8 Bibbin winder

9 Hinged

throat

plate

10

Rotary

top

feed

foot

11

Stitch

regulator scale

12

Slight

for

adjusting

the

stitch

length

Unpacking

13 Wing handle

for

changing

the

direction

of

sewing

14 Sewing

foot

lifter

lever

15 Wing screw

for

the

adjust

·

ment

slide

of

the

stitch

regulator

16 Needle

threat

tension

17

Thread

guide

18

Thread

guide

19

Thread

guide

pin

21

Pushbutton

for

swinging

out

the

throat

plate

22

Sewing

foot

fastening

screw

1. Check

the

packing

for

damage in

the

presence

of

the

carrier

.

2. Check sewing

machine

,

stand

and

accessories

for

any

possible

transport

damage.

3.

Immed

i

ately

notify

any

damage in

the

presence

of

the

carrier

Assembly

1. Check

the

stand

designation.

2. Fasten

the

sew

ing machine

to

the

stand

by

screws

according

to

figs.

11-13

. These illustrations serve as

mounting

instruc

-

tions

and

show

how

the

respective assembled

stands

should

look like.

3. Place

the

driving

belt

on

the

sewing machine driving

pulley

and

place

the

small

stand

flywheel

100

, figs.

11

and

12

.

4.

Tension

the

V-belt as required as swinging

out

the

motor.

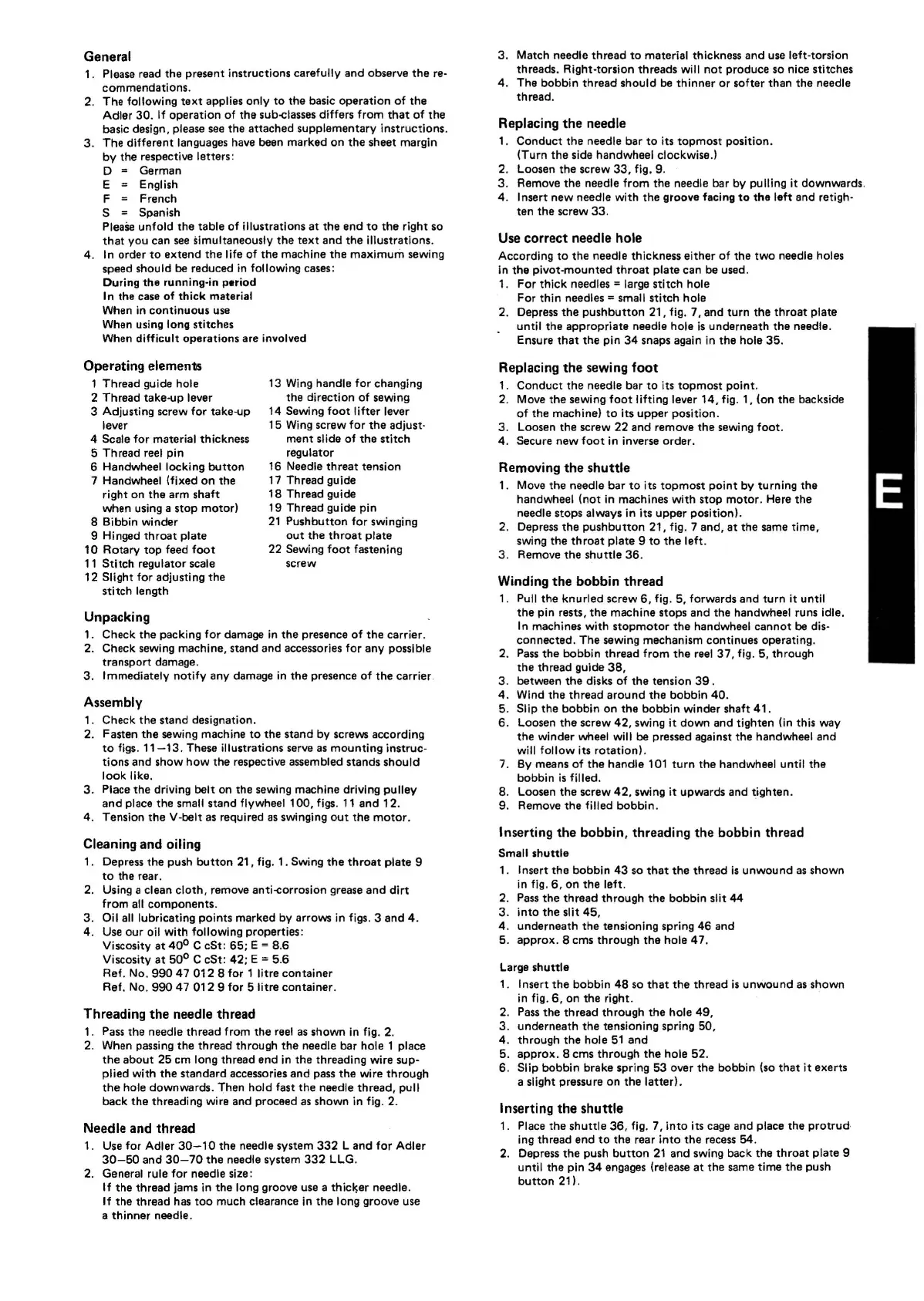

Cleaning and oiling

1. Depress

the

push

button

21,

fig. 1 . Swing

the

throat

plate

9

to

the rear.

2. Using a

clean

cloth

, remove anti-corrosion grease

and

dirt

from

all

components

.

3.

Oil all lubricating

points

marked

by

arrows in figs. 3

and

4 .

4.

Use

our

oil with following

propert

ies:

Viscosity

at

40°

C

cSt

:

65;

E = 8.6

Viscosity

at

50°

C

cSt:

42;

E = 5.6

Ref. No.

990

47

012

8

for

1 litre

container

Ref. No.

990

47

012

9

for

5 litre

container

.

Threading the needle thread

1. Pass

the

needle

thread

from

the

reel as

shown

in fig. 2.

2. When passing

the

thread

through

the

needle

bar

hole 1 place

the

about

25

cm

long

thread

end

in

the

threading wire sup-

plied

with

the

standard

accessories

and

pass

the

wire

through

the

hole

downwards.

Then

hold

fast

the

needle

thread

, pull

back

the

threading

wire

and

proceed

as shown in fig. 2.

Needle and thread

1. Use

tor

Adler

30

-

10

the

needle

system

332

Land

for

Adler

30-50

and

30-70

the

needle system

332

LLG.

2. General rule

for

needle size:

If

the

thread

jams in

the

Jong groove use a thic)ser needle.

If

the

thread

has

too

much clearance in

the

long groove use

a

thinner

needle.

3 . Match

needle

thread

to

mater

ial thickness

and

use left-torsion

threads. Right-torsion

threads

w

il

l

not

produce

so nice

stitches

4 .

The

bobbin

thread

should

be

thinner

or

softer

than

the

needle

thread.

Replacing the needle

1.

Conduct

the

needle

bar

to

its

topmost

position.

(Turn

the

side

handwheel

clockwise.)

2. Loosen

the

screw

33,

fig. 9.

3.

Remove

the

needle

from

the

needle bar

by

pulling it

downwards

.

4.

Insert

new

needle

with

the

groove facing

to

the left

and

retigh-

ten the

screw

33.

Use correct needle hole

According

to

the

needle

thickness ei

ther

of

the

two

needle holes

in

the

pivot-mounted

throat

plate

can

be

used.

1.

For

thick

needles = large

stitch

hole

For

thin

needles = small

stitch

hole

2.

Depress

the

pushbutton

21, fig.

7,

and

turn

the

throat

pl

ate

until

the

appropriate

needle

ho

le is

underneath

the

needle.

Ensure

that

the

pin

34

snaps again in

the

hole

35

.

Replacing the sewing

foot

1.

Conduct

the

needle

bar

to

its

topmost

point.

2. Move

the

sewing

foot

lifting lever

14,

fig.

1,

(on

the

backside

of

the

machine)

to

its

upper

position.

3.

Loosen

the

screw

22

and

remove

the

sew

ing

foot.

4.

Secure

new

foot

in inverse order.

Removing

the

shuttle

1.

Move

the

needle

bar

to

its

topmost

point

by

turning

the

handwheel

(not

in machines

with

stop

motor.

Here

the

needle

stops

always

in its

upper

position).

2. Depress

the

pushbutton

21, fig. 7

and,

at

the

same

time,

swing

the

throat

plate

9

to

the

l

eft.

3 . Remove

the

shuttle

36

.

Winding

the

bobbin thread

1. Pull

the

knurled

screw

6,

fig.

5,

forwards

and

turn

it

unt

il

the

pin rests,

the

machine

stops

and

the

handwhee

l runs idle.

In machines

with

stopmotor

the

handwheel

cannot

be

dis-

connected

.

The

sewing

mechan

i

sm

continues

operating.

2. Pass

the

bobbin

thread

from

the

reel

37,

fig.

5,

th

r

oug

h

the

thread

guide

38

,

3 . between

the

disks

of

the

tension

39

.

4 . Wind

the

thread

around

the

bobbin

40.

5 . Slip

the

bobbin

on

the

bobbin

winder

shaft

41.

6 . Loosen

the

screw

42,

swing

it

down

and

tighten

(in

th

is way

the

winder wheel will

be

pressed against

the

handwhee

l

and

will follow its

rotation).

7. By means

of

the

handle

101

turn

the

handwheel until t

he

bobbin

is

filled.

8 . Loosen

the

screw

42,

swing

it

upwards

and

tighten.

9 . Remove

the

filled

bobbin

.

Inserting

the

bobbin,

threading

the

bobbin thread

Small

shuttle

1.

Insert

the

bobbin

43

so

that

the

thread

is

unwound

as

shown

in fig. 6,

on

the

left.

2. Pass

the

thread

through

the

bobbin

slit

44

3.

into

the

slit

45,

4.

underneath

the

tensioning spring

46

and

5 .

approx

. 8

ems

through

the

hole

47

.

Large

shuttle

1. Insert

the

bobbin

48

so

that

the

thread

is

unwound

as

shown

in fig.

6,

on

the

right.

2. Pass

the

thread

through

the

hole

49

,

3.

underneath

the

tens

i

oning

spring 50,

4.

through

the

hole

51

and

5.

approx

. 8

ems

through

the

hole

52.

6.

Slip

bobbin

brake

sp

ring 53 over

the

bobbin (so

that

it

exerts

a slight pressure

on

the

latter).

Inserting the shuttle

1. Place

the

shuttle

36,

fig. 7,

into

its cage

and

place

the

protrud

,

ing

thread

end

to

the

rear

into

the

recess

54.

2. Depress

the

push

button

21

and

swing back

the

throat

plate

9

until

the

pin

34

engages (release

at

the

same

time

the

push

button

21

).

From the Library of Superior Sewing Machine & Supply LLC

Loading...

Loading...