INSTALLATION

MECHANICAL INSTALLATION

The detector must be bolted securely in position, but do not twist or strain it in any way.

Nothing should rest on the search head or touch the sides of it.

If a conveyor is used, all feet must be firmly on the floor. The conveyor must not rock or move. Twisting of

the conveyor when product enters the search head may cause false triggers. An unbalanced conveyor motor

could also be a source for unwanted vibration.

All cover screws, bolts, etc., in the vicinity of the detector must be tight for correct operation. Two pieces of

metal making intermittent contact may cause false triggers.

Do not modify the metal detector or its wiring in any way.

Do not attach rollers, guide plates, markers, or electronic sensing devices to any part of the search head.

Product pipes with emulsions or gravity system product chutes should pass through the center of the detector

opening, without touching the walls of the aperture.

The product being inspected should pass through the center of the metal detector opening. The product must

not make contact with any part of the search head. Non-metallic guides should be used if necessary.

WARNING: Do Not Weld anywhere on the unit with the metal detector head attached.

Welding on the unit WILL DESTROY the electronics of the detector and void any and all

warranties.

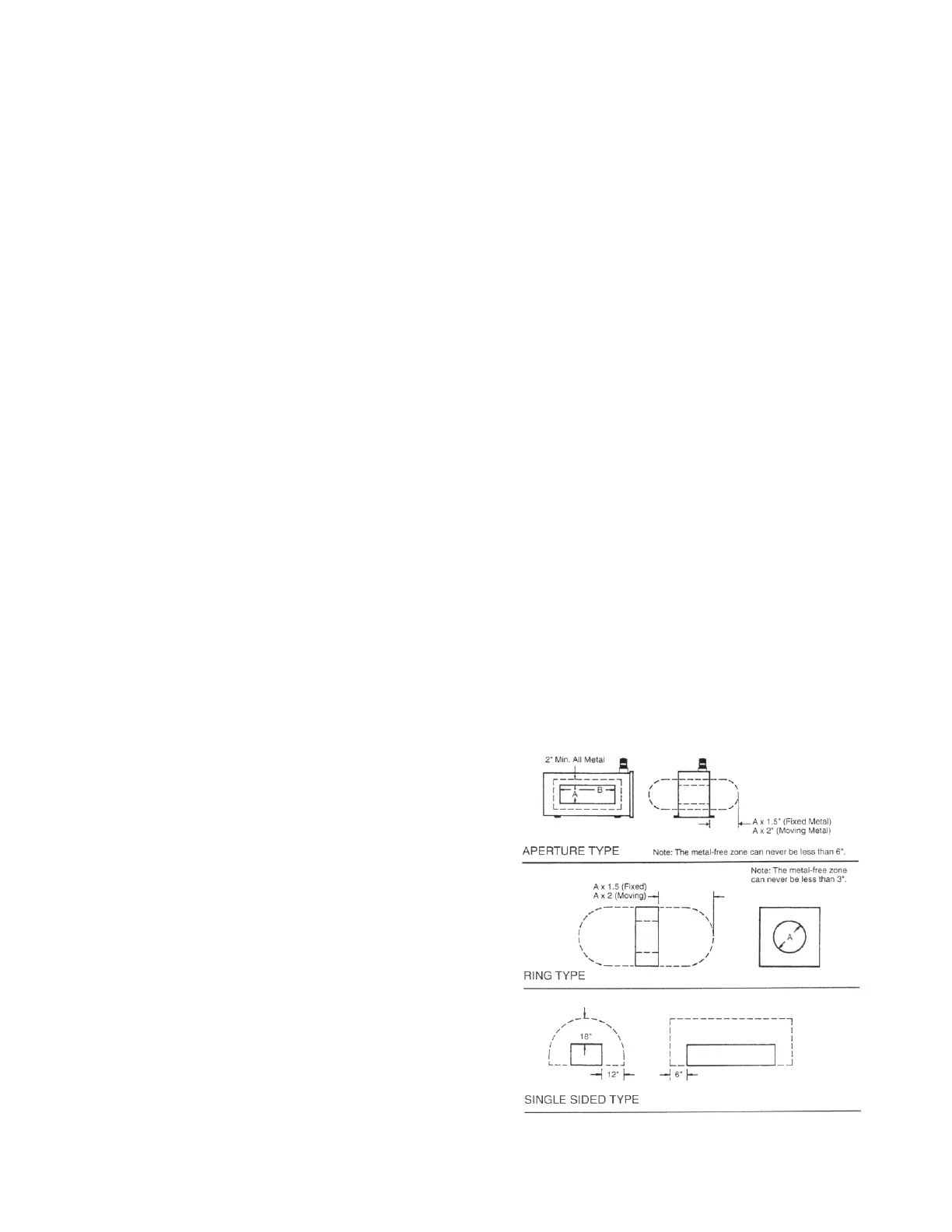

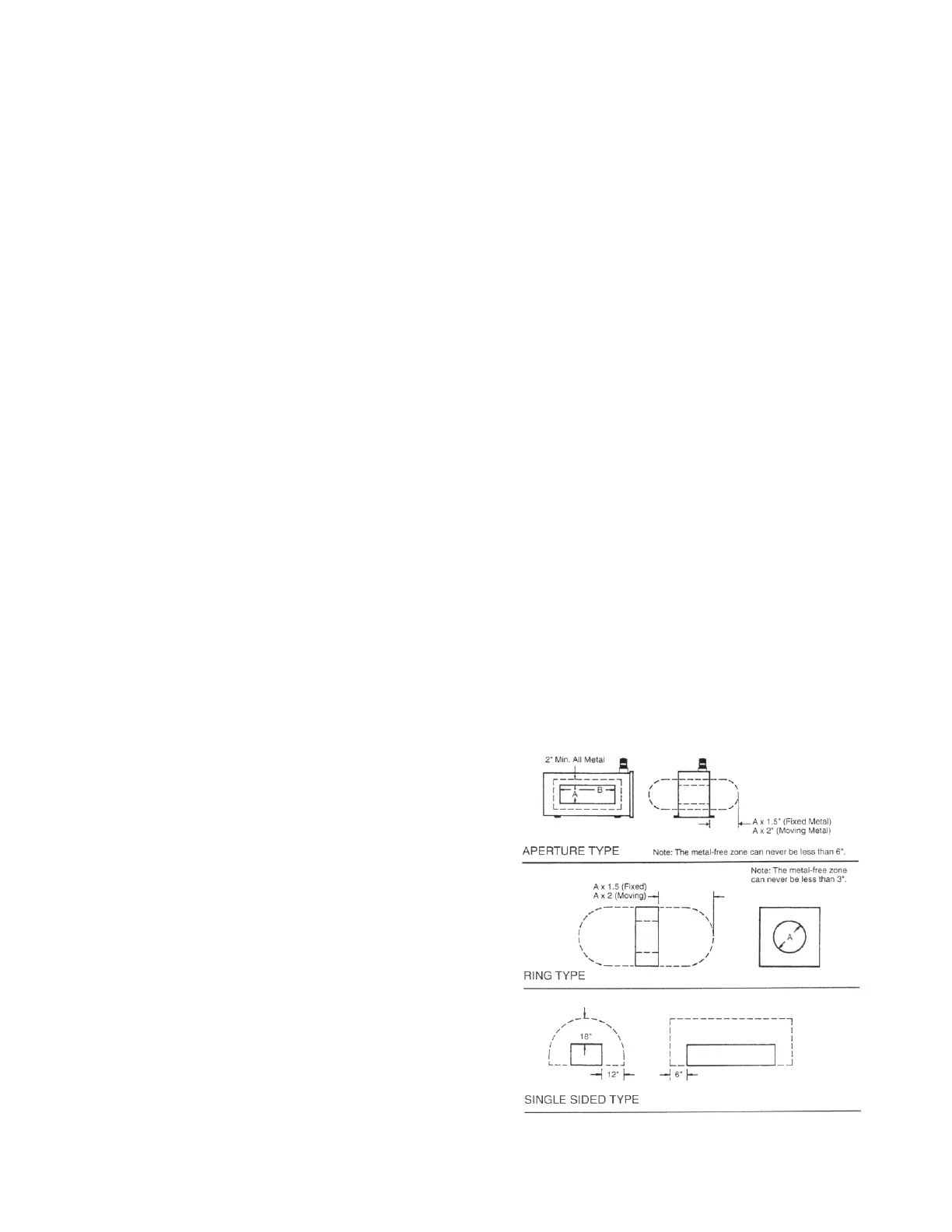

METAL FREE ZONE

The electro-magnetic field is created inside the

detector’s enclosure; however, some field emanates out

of the aperture on both sides and forms the metal free

zone (“MFZ”). Generally, the practical size of the

leakage is 1½ times the (smaller) aperture dimension,

and no metal should be allowed in this area. Large

moving metal should be kept 2 times away. Special

detectors are available for applications which demand a

substantially reduced MFZ.

Loading...

Loading...