60

IVEDPY 1110 - 4879010_01

The unit must be connected directly to

an electrical outlet or to an indepen-

dent circuit.

WARNING: WARNING: it is com-

pulsory to connect the power cables

Phase (L) and Neutral (N) to the

respective terminals, do not to reverse

the connections, and observe the wir-

ing diagram.

Install a device, main switch, or elec-

tric plug so you can fully disconnect

the device from the power supply.

To protect the unit against short cir-

cuits, fit an omnipolar thermal-mag-

netic trip 2A 250V (IG) to the power

line with a minimum contact opening

distance of 3mm.

For installations with three-phase power

supply, the following precautions

should be considered:

1. In the presence of breakers or ther-

momagnetic switches 3P + N, the trig-

gering current must be at least 170%

of the total load absorbed by the fan

coils for each phase.

2. The section of the neutral wire must

be of a dimension taking into consid-

eration the operating current equal to

170% of the total load absorbed by

the fan coils for each phase.

CHARACTERISTICS OF THE

CONNECTION CABLES

Use H05V-K or N07V-K type cables

with 300/500 V with insulation, routed

through pipes or raceway.

Use a cable with a minimum section of

1mm

2

.

All the cables must be in pipes or race-

ways until they are inside the fan coil.

The cables leaving the pipe or raceway

must be positioned in such a way that

they are pulled or twisted and are any-

way protected from outside agents.

Stranded cables can only be used with

cable terminals. Make sure that the

strands of the wires are inserted properly.

The wiring diagrams are subject to con-

tinuous updates, so it is essential to

use those on the machine as your ref-

erence.

The control panel may not be fitted on a

metal wall unless this is connected to

a grounded outlet permanently.

Before installing the control panel, read

the instructions carefully and config-

ure the panel if necessary. Some con-

trol panels require the combination

with components supplied as acces-

sories, check availability.

WARNING: Make sure the control

panel supports the load of the electric

motor, otherwise placed an SIT3 inter-

face accessory between the fan and

the control panel.

WARNING: The units that are

equipped with VMF series thermostats

must be combined with an VMF-SIT

interface accessory.

When combining to control panels,

the relative wiring diagram must be

respected.

If present, connect the valve and sensor

to the control board, in the positions

indicated in the wiring diagram. In

installations with a 3-way valve, the

minimum water temperature sensor

must be relocated from its standard

mounting in the coil assembly to the

delivery hose upstream of the valve.

If the highest speeds of the motor are

required, change the connection

to the control board on the electric

motor. Follow the wiring diagram.

WARNING:check whether the

installation has been carried out cor-

rectly. FOLLOW THE CHECKING

PROCEDURES indicated in the con-

trol panel manuals.

ELECTRICAL CONNECTIONS

- Make the hydraulic connections.

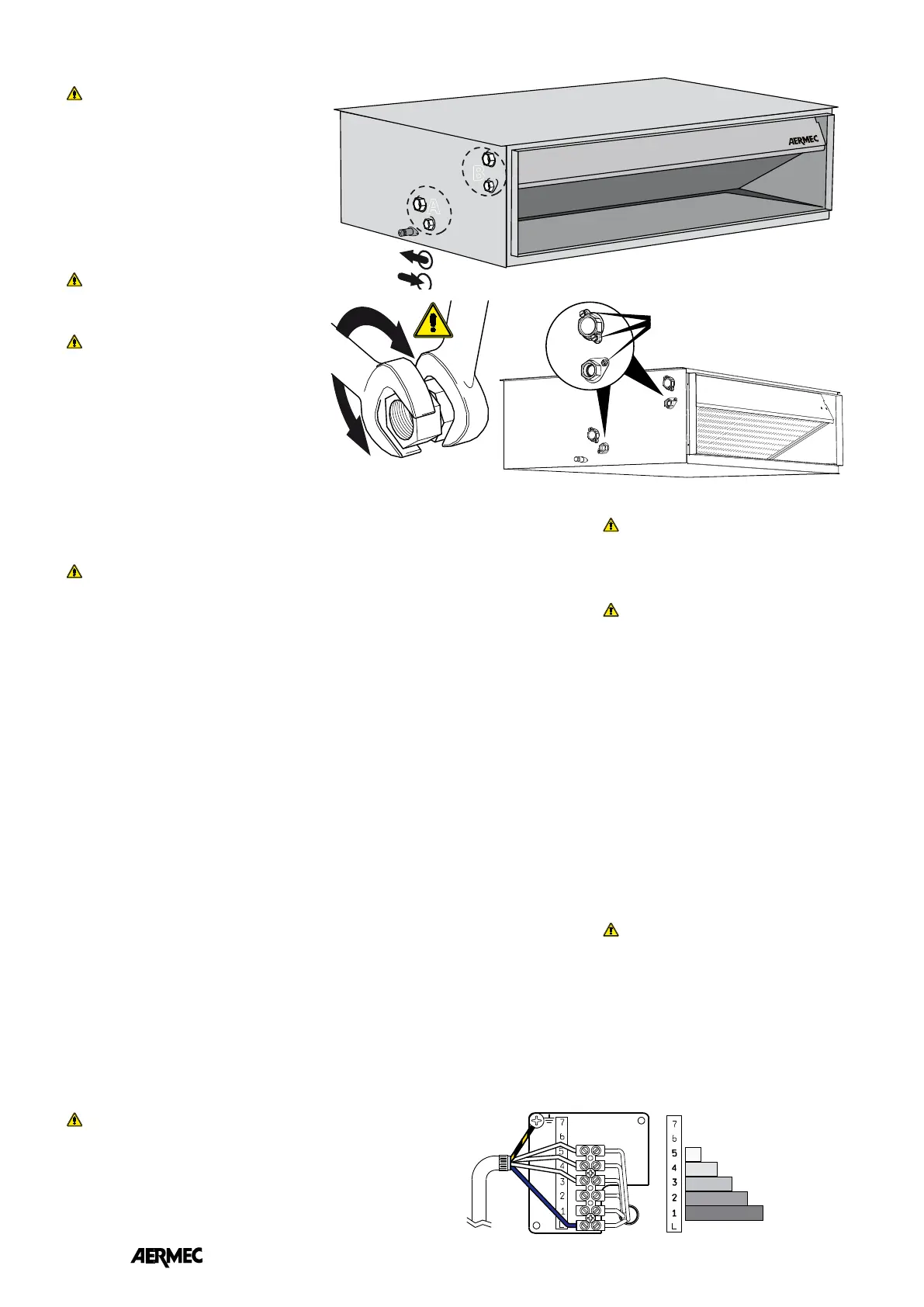

WARNING: Always use a wrench

and counter-wrench to fix the pipes.

Refer to the size data for the position,

type and diameter of the hydraulic

connections.

You are advised to adequately insulate

water lines and/or fit the auxiliary

condensate drain tray (available as an

accessory), to prevent dripping during

the cooling function.

After installing, check the seal on the

connections.

WARNING: Bleed the hydraulic

system. The relief valves are positioned

at the top of the coil near the hydraulic

fittings.

WARNING: To discharge the unit,

use the exhaust valves located in the

lower part of the coil near the hydraulic

fittings.

PLUMBING CONNECTIONS

B

A

IN

OUT

B

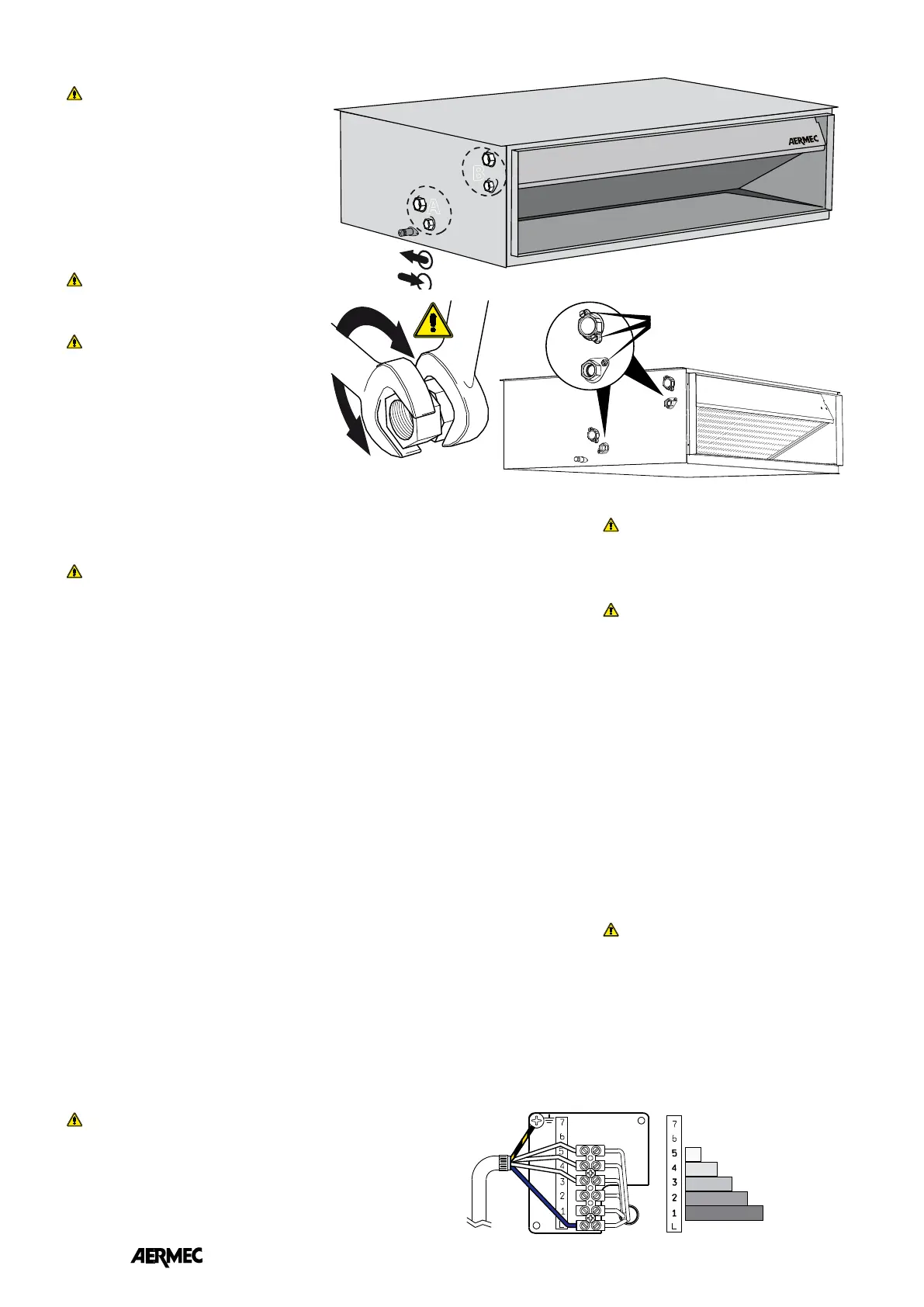

Motor control board The 5 speeds of the motor

(5) minimum

(1) maximum

(4 - 3 - 2 )

intermediate

WARNING: VED is supplied with connections to terminals

5 - 4 -3.

To make use of the higher speeds (terminals 2 and 1),

disconnect the wires from the terminals of the default speeds

and connect them to the terminals of the desired speed.

The three speeds must always be adjacent.

Relief valves and discharge

water from the coil

Loading...

Loading...