Introduction

01-20 79026547 Rev. A

TIGHTENING STRAIGHT THREAD

FITTINGS

Straight thread hydraulic fittings require precise

tightening. Overtightening ruins sealing surfaces and

require replacement of damaged parts.

Proper initial tightening depends on mating parts to be

connected. Proceed as follows:

An adapter fitting (37° flare) connected to a double flare

tube assembly, fitting must be tightened finger tight and

wrenched 1/2 turn (for single flare, 1/4 turn).

An adapter fitting (37° flare) connected to a hose, fitting

must be tightened finger tight and wrenched 1/4 turn.

An o-ring adapter fitting connected to a solid port, fitting

must be tightened so backup washer contacts face of

boss after fitting has been properly positioned.

To retighten after initial tightening, as in service work, both

tube and hose connnections should be tightened finger

tight and wrenched 1/4 turn. O-ring fittings should be

tightened as for initial assembly.

JIC SWIVEL NUTS (37° SEAT). Following values are

maximum recommended torque values for JIC (37° seat)

swivel nuts either swaged or brazed type. Swivel nuts

normally withstand torque for a minimum of 15 repeated

assemblies.

Torque required to seal swivel female fittings or hose

couplings to a male connector depends on many

variables such as medium, pressure, surface finish, etc.

Following values are intended only as a guide for

maximum values fittings may be subjected to.

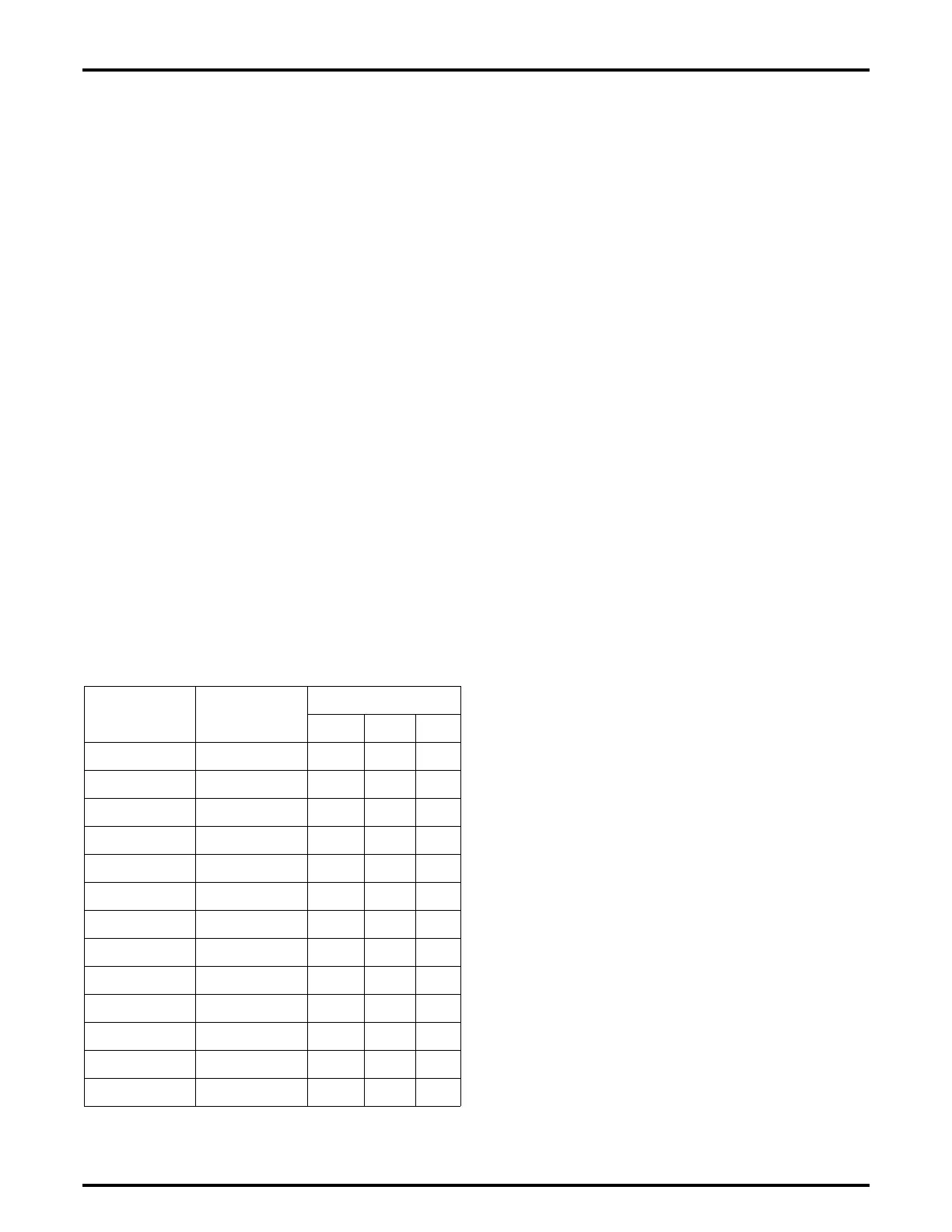

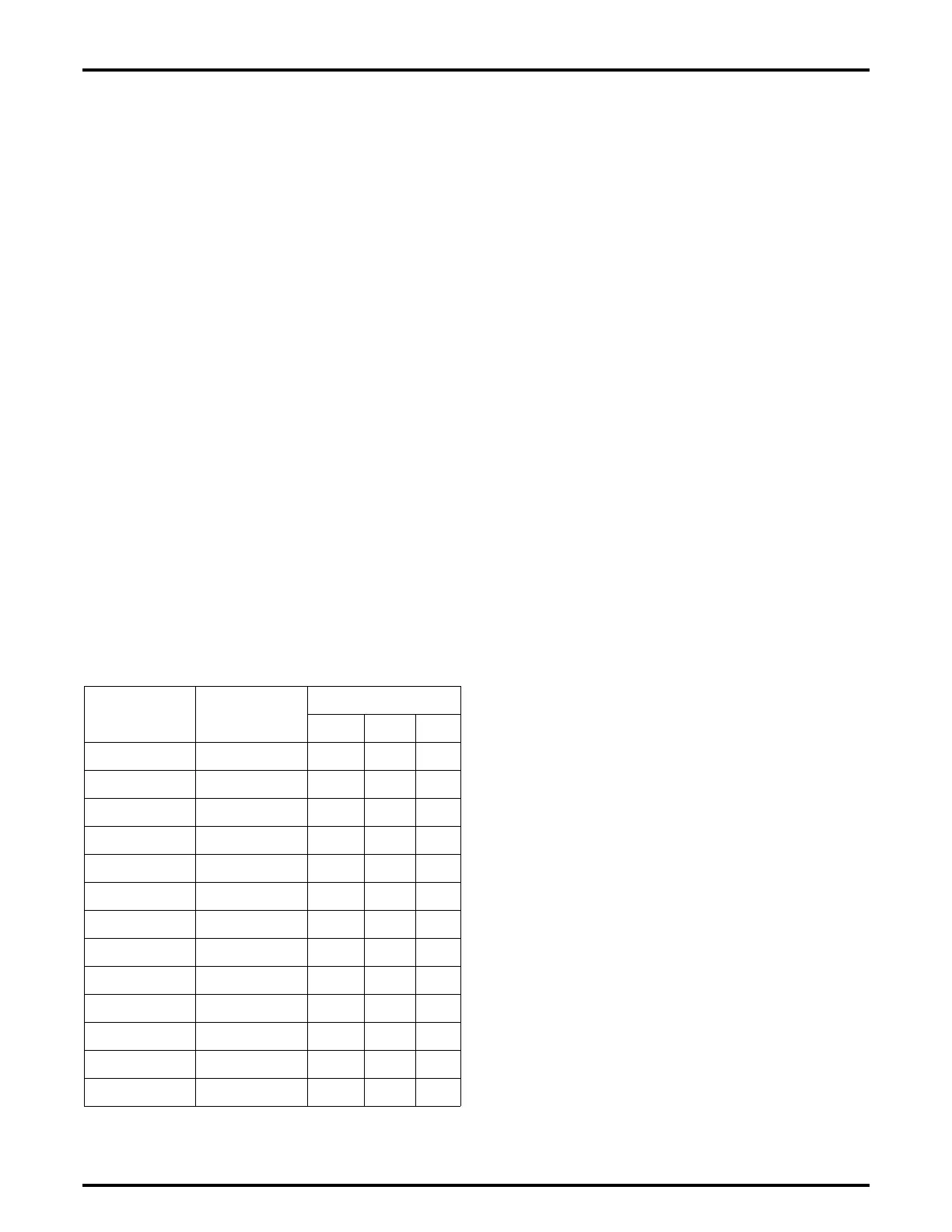

DASH SIZE TUBE O. D.

(REF.)

TORQUE MAX

N-m lb-in lb-ft

-4 1/4 12 110 9

-5 5/16 20 180 15

-6 3/8 27 240 20

-8 1/2 40 360 30

-10 5/8 54 480 40

-12 3/4 95 840 70

-14 7/8 110 980 80

-16 1 120 1080 90

-20 1 1/4 160 1440 120

-24 1 1/2 180 1575 130

-32 2 400 3600 300

-40 2 1/2 540 4800 400

-48 3 680 6000 500

Find manuals at http://best-manuals.com/search?&s=CHAL-79026547

Loading...

Loading...