10

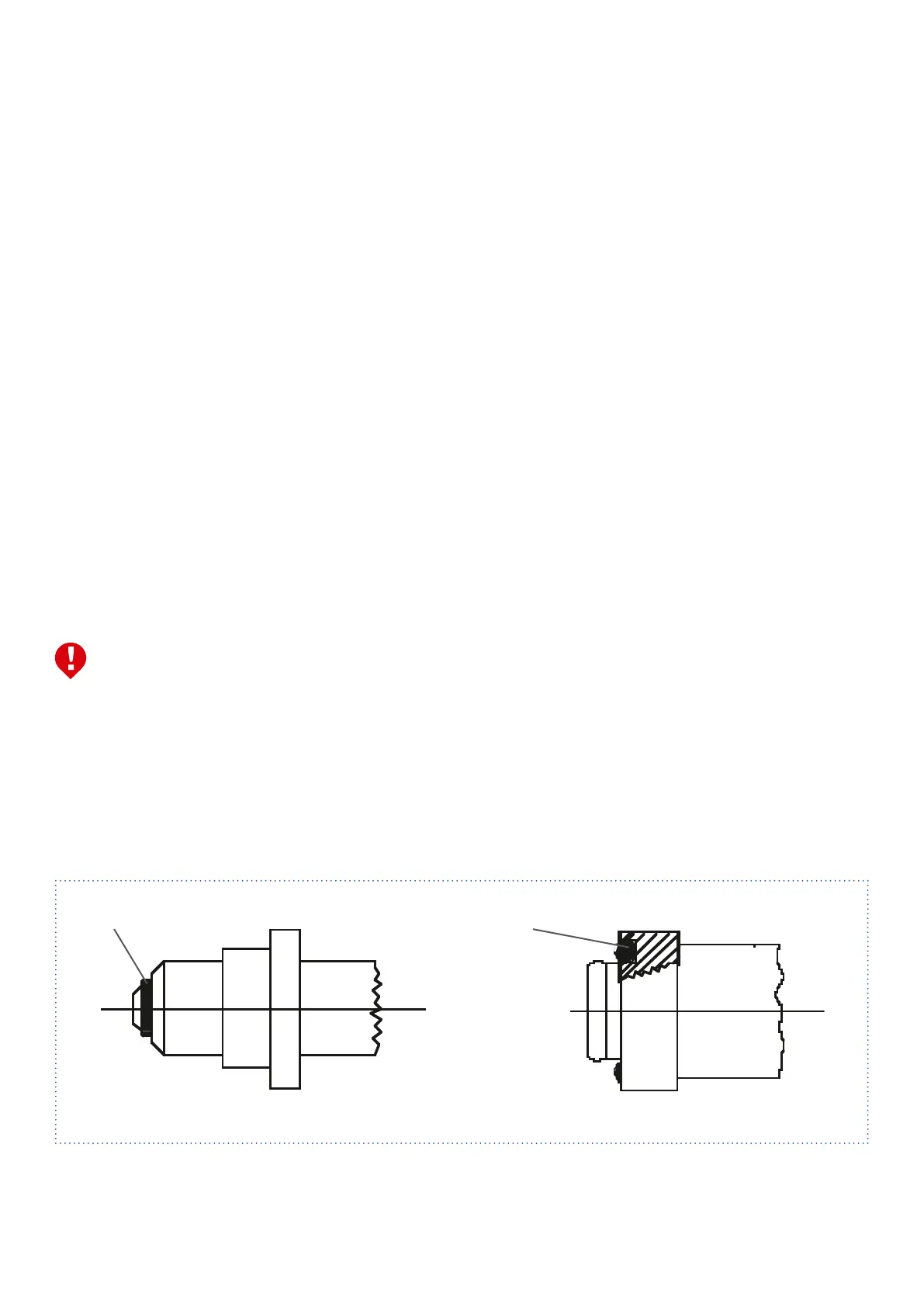

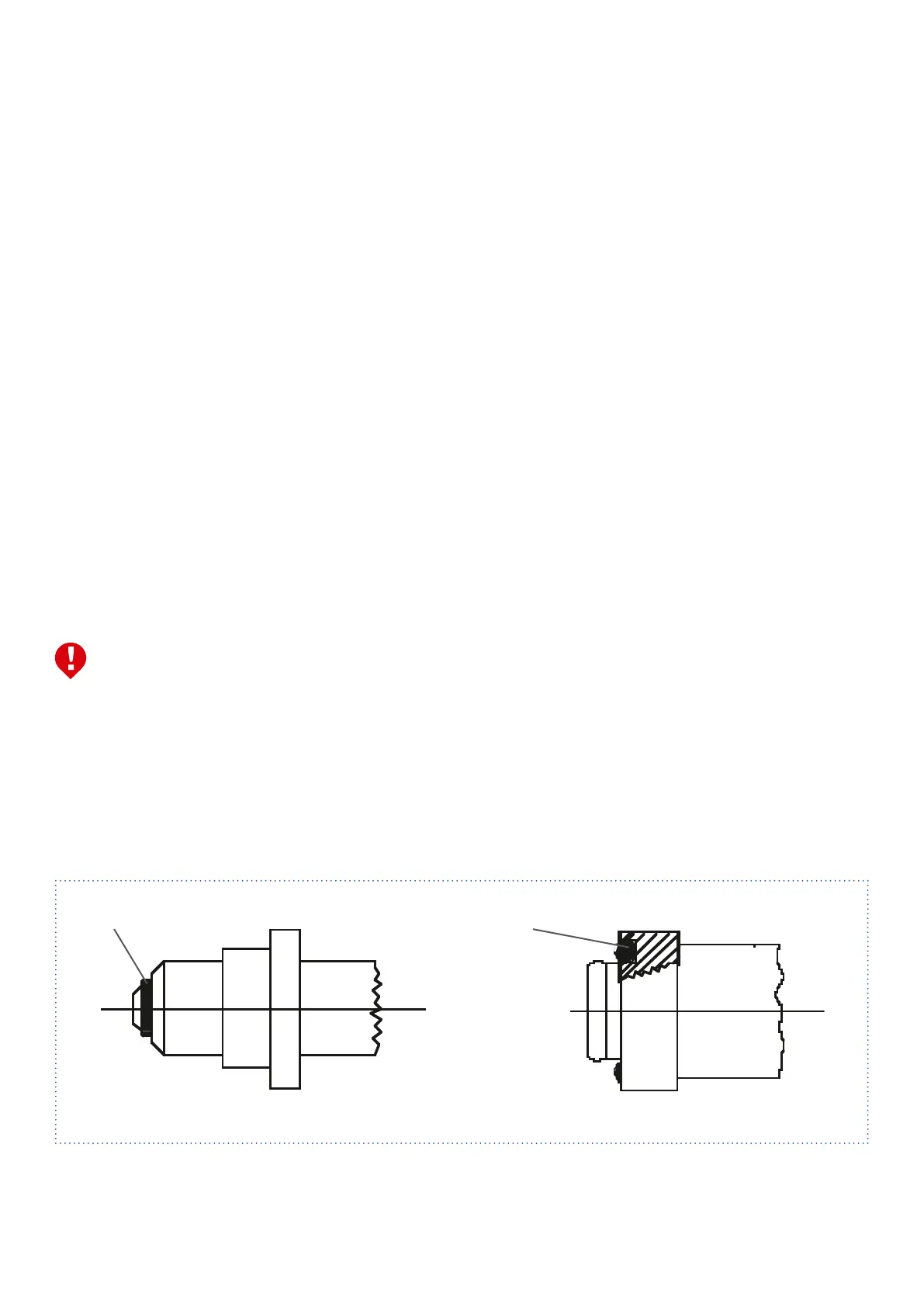

6.1.6 Check connection threads and connection surfaces

of the cylinder valves and the gaskets for proper con-

ditionandfit(seeFig.8.10 / 8.11).MountFlexible

hoses / pigtailswithhandconnection(Oringseal)

without tools on the cylinder valve. Before connecting

theflexiblehose / pigtail,brieflyopenthecylinder

valve once and then close it again, to blow out any dirt

particles that may be present. Do not stand in front of

the outlet opening of the of the valve (7) and make

sure that no danger arises from the escaping gas.

Good ventilation must be provided. Do not blow out

flammable, corrosive, toxic and irritant gases.

6.1.7 At the outlet of the pressure regulator (12), the orifice

plate included in the scope of delivery or optionally

supplied must be inserted or mounted, depending on

the type of gas.

Adapt the outlet to the pipeline by using a compres-

sion fitting. Shortly after the outlet of the pressure

regulator (12), a main line shut-off valve and, if neces-

sary, a safety valve should be installed in the pipeline.

6.1.8 When toxic or flammable gases are used, safe dis-

charge of the purge gas must be ensured. The exhaust

gas pipes must be connected to the outlet connection

of the blow-off valve on the pressure regulator (3 or 8)

and to the purging valves (1) by using compression

fittings.

6.1.9 After successful installation, the system must be purged

with dry inert gas of suitable quality (e.g. nitrogen). All

detachable connections must be leak tight. The tight-

ness test must be certified and checked repeatedly at

regular intervals.

6.1 Assembly

6.1.1 Assembly may only be carried out by persons who are

trained, experienced in the field of application (gas

installations) and have been instructed in safety tech-

nology. The trainings and instructions must be carried

out in regular intervals.

6.1.2 The pressure manifolds shall be supplied pre-assem-

bled as far as possible. Check scope of delivery in

accordance with the datasheet. Check on the basis of

the type plate whether the station is suitable for the

intended use (pressure, gas type, material).

6.1.3 Determine the dimensions of the drill holes according

to the data sheet and fasten the base plate with ap-

propriate screws.

6.1.4 The Cylinder brackets must be fixed on a Wall or similar.

The support must be sufficient to prevent the Cylinder

from falling down. When doing this the outer edges of

the base plate should be vertical and approx. 3/4 of

thecylinderheight(foracylinderheightof1500 mm,

thisisapprox.1100 mm)ashorizontalorientation.

6.1.5 Hose lines / spiral tubes (5) via adapter / check valve

or check valve with filter (antiflapping). First screw the

adapter / check valve into the station inlet first.

The tool must only be applied to the narrow hexagonal.

Then mount the hose line / spiral pipe on the check valve

while holding it against the fitting body with a second wrench.

6 Installation

O-Ring O-Ring

Abb. 8.10 300 bar Abb. 8.11 200 bar

Loading...

Loading...