14

9.2 Maintenance

Even though the equipment is reliable, it must be checked

periodically.

Since this task requires some precautions, it must be done

exclusively by a qualified technician.

The periodicity of this verification depends essentially on the

usage of the equipment (intensive, moderate, occasional).

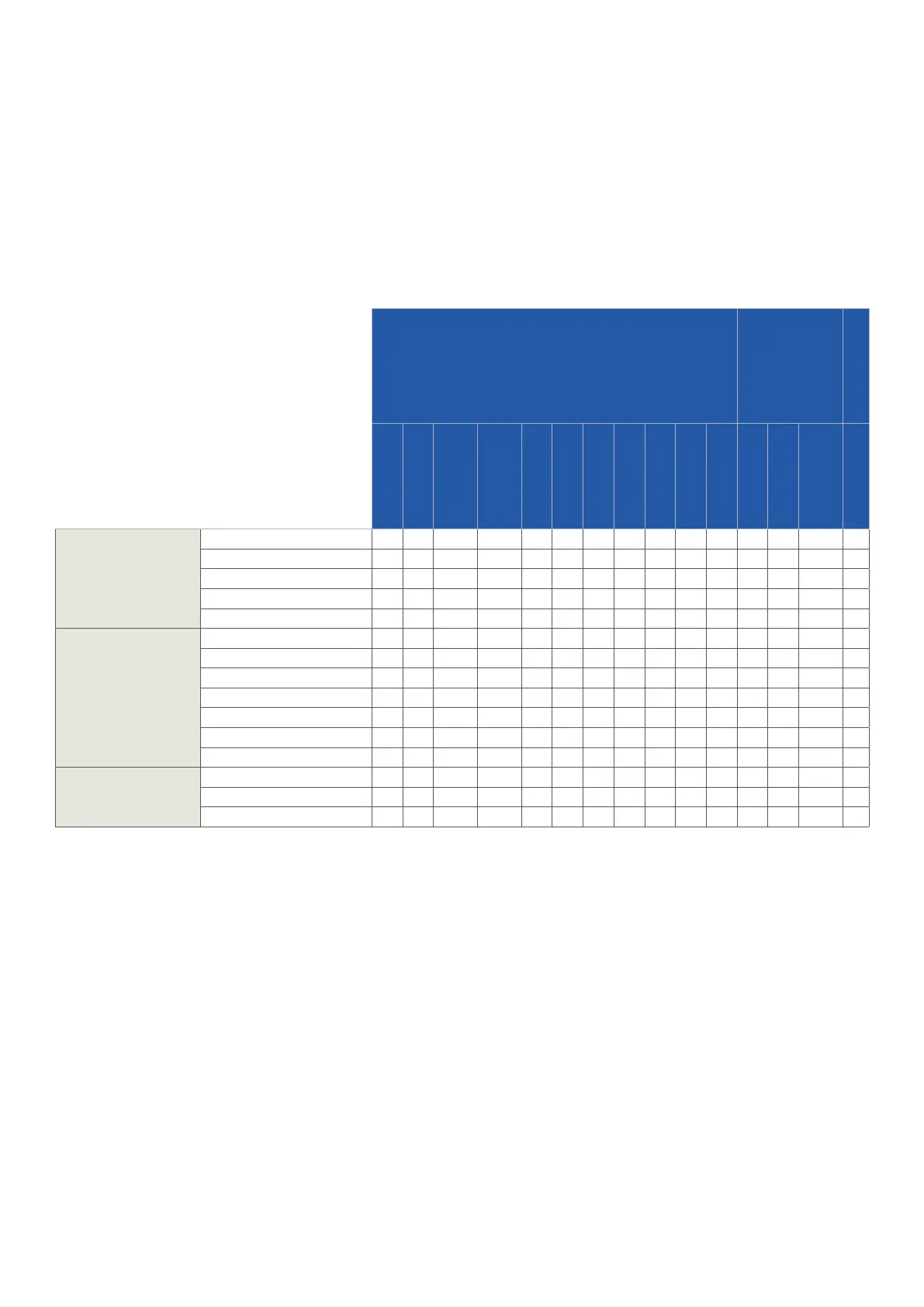

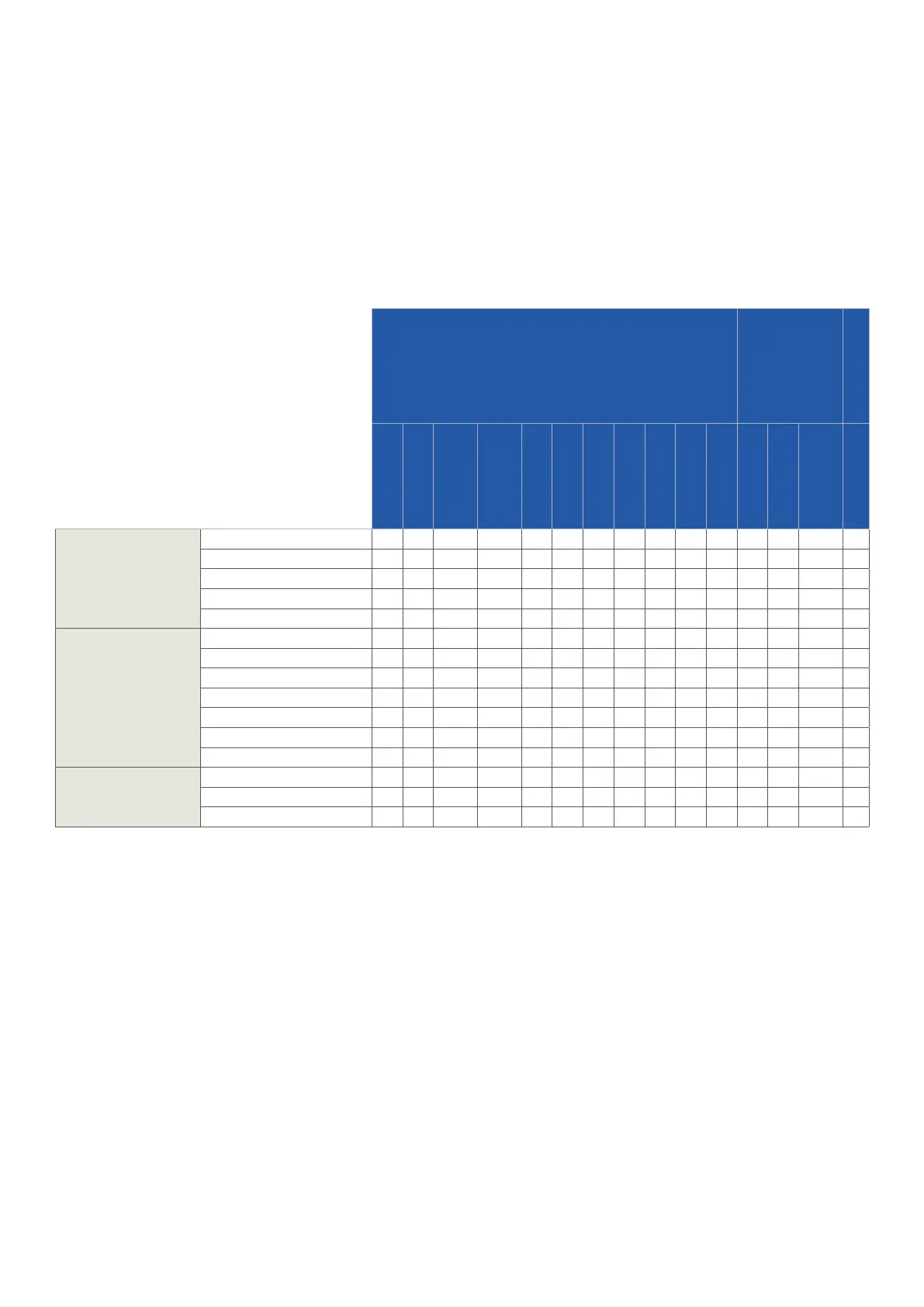

We suggest the use of the following table to ensure an opti-

mum usage of your equipment:

V – to verify

C – to change

Periodically

Annually

Every 5 years

Leakage

Operation

condition of

threads

Sealing of

closure

Fastening

Appearance

Setting

Safety

Cleanliness

Labelling

Seal

Setting

Filter

Electrical

continuity

Cylinder/Manifold

connection

Flexible hoses /Pigtails V V V V V V C V C

Safety cable V V C

Racks V V

Chain V V

Fittings / Filters V V V V C

Manifold

Support plate V V V V V

HP Valves V V V

Regulators V V V V V V

LP Valves V V V

Relief valves V V C

Pressure Gauges V V V

Filters C

Others

2nd Stage reducer V V V C V C

Monitoring system V V V

Pipe network V V V V V V C V

The system should be checked by the manufacturer once a

year for functional and operational safety. We recommend a

maintenance contract – please do not hesitate to contact us.

The annual check of the flame back arrestors at downstream

point of us is required by law. The proof of this must be pro-

vided by the operator.

Flexible hoses must be checked as required, at least at inter-

vals within one year, in terms of their condition (integrity and

tightness) by an expert or by the manufacturer.

Loading...

Loading...