8

GB

IMAT PT- E

6.2) DISASSEMBLY

When disassembly of actuator is required for maintenance,

firstly remove the actuator from the valve. Before performing

any disassembly operations it is important to verify that the

actuator is not pressurised.

Always use caution and double check that the ports 2 and

4 are vented and are free from any accessory and/or device.

When the actuator is a spring return unit, make sure that the

actuator is in the failed position and with pistons completely

inwards before disassembling.

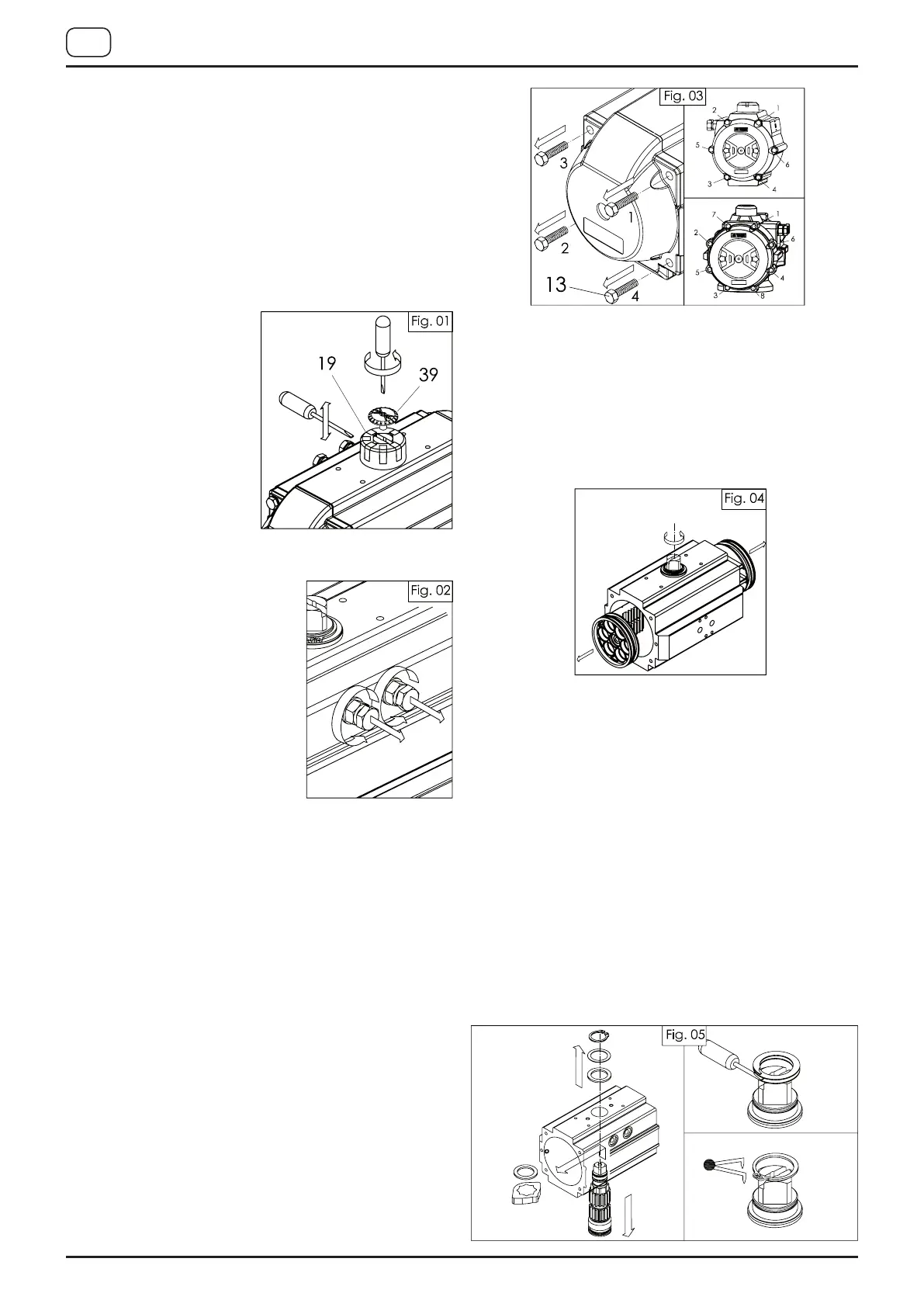

A) Removal of position indicator (Part N° 19), figure 01:

• Remove cap screw (39,

39.1, 39.2) if fitted.

• Lift position indicator

(19) off shaft, it may be

necessary to pry gently

with a screwdriver.

B) Removal of stop cap screws (Part N° 02), figure 02:

• Remove both stop cap screws

together with nut (04) and

washer (03).

• Remove stop screw o-rings

(11) and discard if replacing all

soft parts.

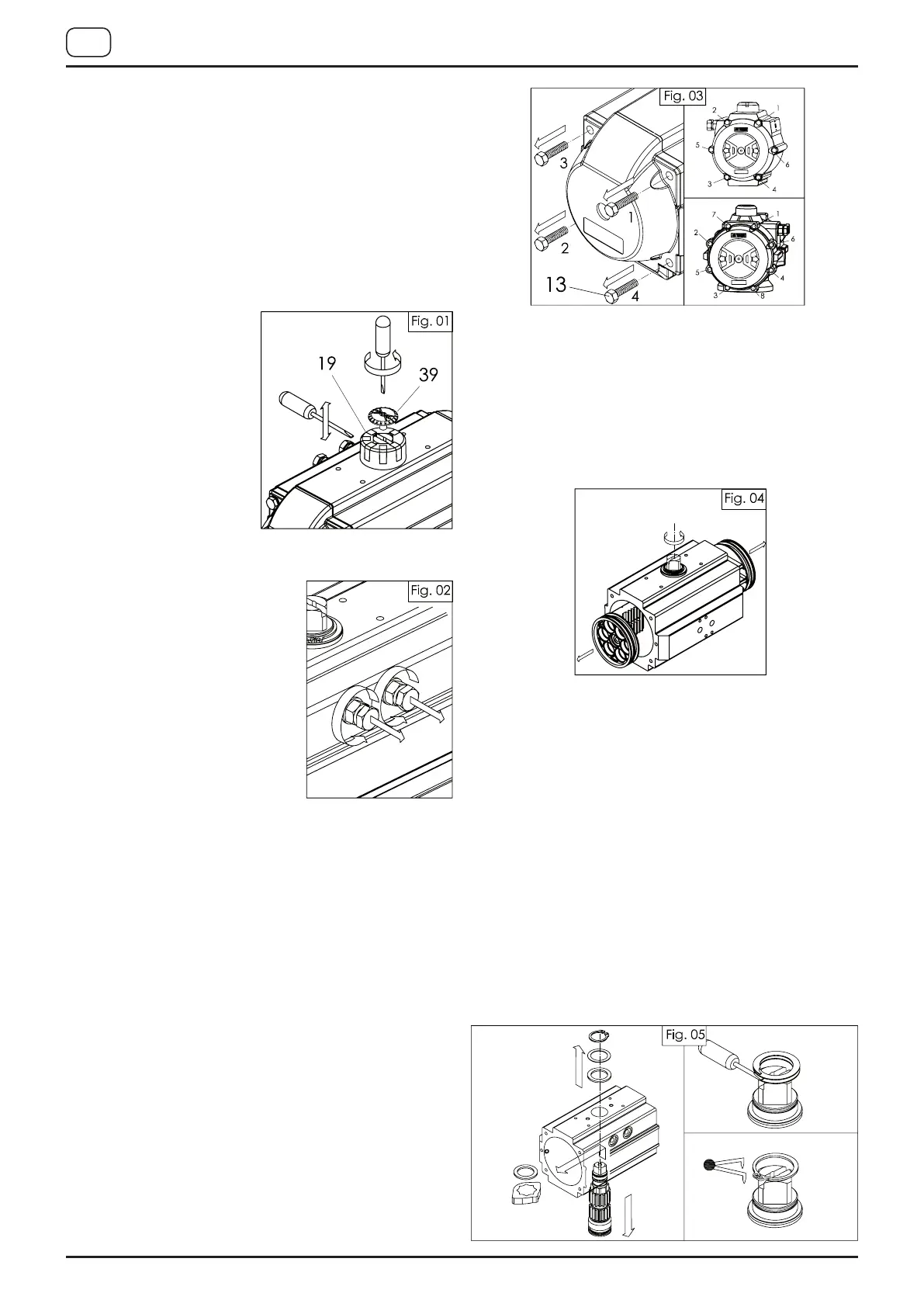

C) End caps disassembly (Part N° 30), figure 03:

• End caps disassembly for spring return actuators (disas-

semble one end cap at a time).

Unscrew the end cap bolts (13) in the sequence shown

in figure 03, until the end-caps are free from springs force

(for PT045 and PT050 N 20-23 turns of the screws, for

PT100 to PT800 4-5 turns of the screws).

Then completely unscrew the screws and remove the

end-cap and the springs.

If there is still force on the end-caps after unscrewing as

indicated above, this may indicate that spring cartridge is

damaged or that the pistons are not completely closed,

so any further disassembly should be discontinued. Fur-

ther disassembly of the end caps may result in injury.

• End caps disassembly for double acting actuators (dis-

assemble one end cap at a time)

Unscrew the end cap bolts (13) in the sequence shown

in figure 03, until the screws are completely unscrewed

and the end caps are free.

• Remove the o-rings (14) using a screwdriver. Discard

soft parts if replacing.

• Only for actuators with adjustment 50% or 100%, re-

move the nut 04R, the washers 03R and o-rings 11R

and discard soft parts if replacing.

D) Pistons disassembly (Part N° 40), figure 04:

• Holding the body (50) in a vice or similar device, rotate

the drive shaft (60) until the pistons (40) are released.

Caution: air pressure should not be used to remove the

pistons from the body.

• Remove o-rings (16) using a screwdriver. Remove the

piston back (05) and piston head (15) bearings.

• Discard bearings when replacing all soft components.

E) Drive shaft disassembly (Part N° 60), figure 05:

• Remove the spring clip (18) using snap-ring pliers or

screwdriver for spiral rings, remove the thrust washer

(10) and the external thrust bearing (08). Apply down-

ward force to top of drive shaft (60), until it is partially

out of the bottom of the body when it is possible to re-

move the internal thrust bearing (08) and the octi-cam

(01), then push the pinion (60) completely out of the

body. If pinion is not easily removed, gently tap the top

of the shaft with a plastic hammer.

• Remove top (06) and bottom (07) pinion bearings and

top (20) and bottom (21) pinion o-rings.

• Discard bearings (06) and (07), internal and external

thrust washer (08) and o-rings (20) and (21) if replacing

the soft components.

All the components disassembled and not replaced will

have to be cleaned and inspected for wear and before

reassembly, if necessary, also replace the plugs (09).

Loading...

Loading...