9

6.3) ASSEMBLY:

Prior to assembly, ensure that:

• all the components are perfectly clean and in good con-

dition.

• the spare parts and the lubricant used are suitable

for the operating temperature of the actuator (see Air

Torque technical data sheets).

• Note: The lubricants suitable for the various operat-

ing temperatures (Standard, HT and LLT actuators) are

available in Air Torque.

Only for “standard” actuators, for temperature from

-40°C (-40°F) to +80°C (+176°F), it is possible to use

lubricant Dow Corning type Molykote

®

G-2003.

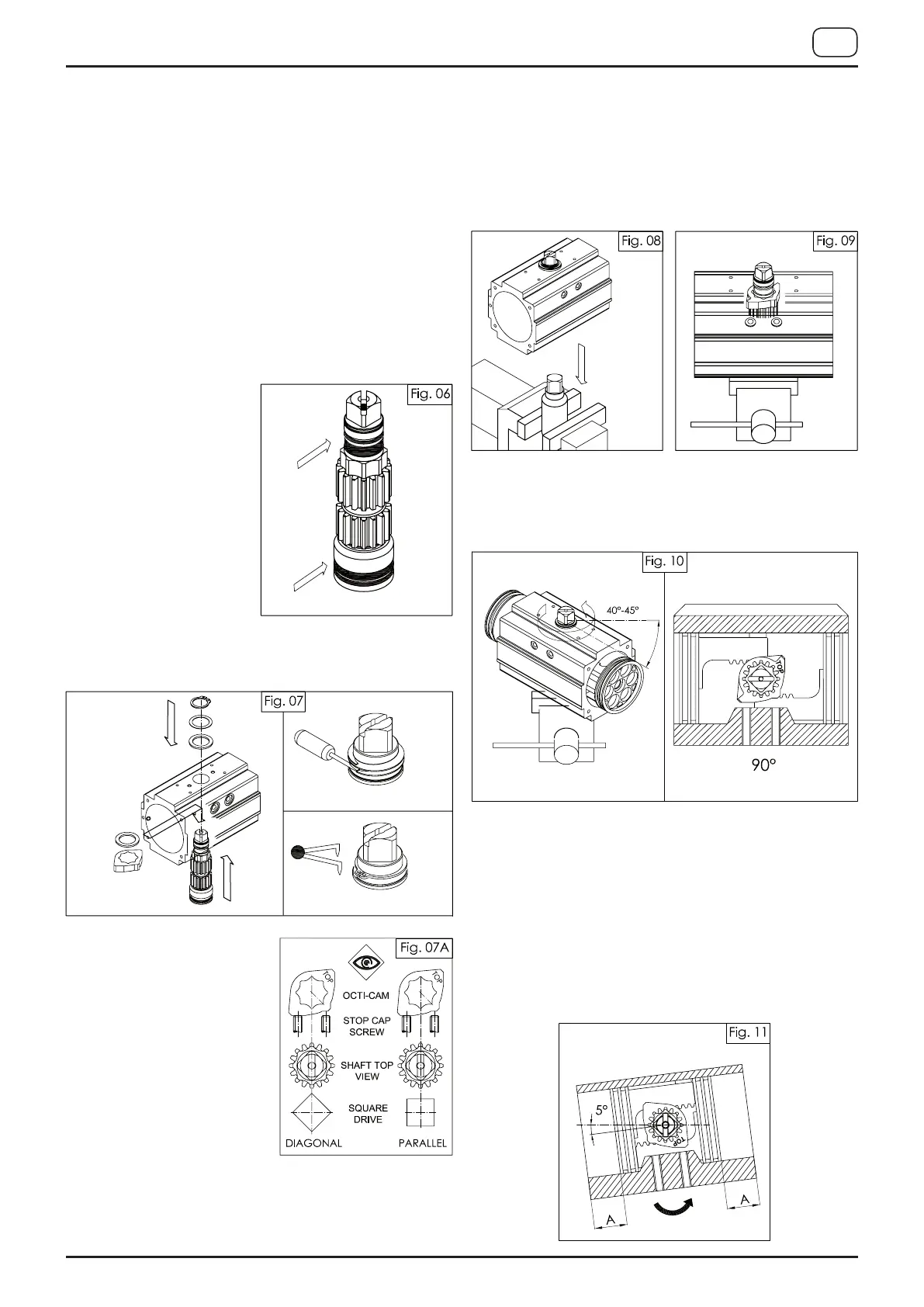

A) Drive shaft assembly (Part N° 60), figures 06, 07 and

07A:

• Install top (06) and

bottom (07) bearings,

grease and insert the

bottom (20) and top

(21) pinion o-rings onto

the shaft.

• Grease the outside sur-

face of the drive shaft

as shown in figure 06.

• Insert partially the drive

shaft (60) in the body

(50), install octi-cam

(01) in the correct posi-

tion as shown in figures

07 and 07A, related to the bottom and top of the drive

shaft and the rotation of the actuator when energised.

Install the internal thrust

bearing (08). Insert com-

pletely the drive shaft in

the body.

• Fit external thrust bearing

(08), thrust washer (10)

and then external spring

clip (18) using snap ring

pliers or screwdriver for

spiral rings.

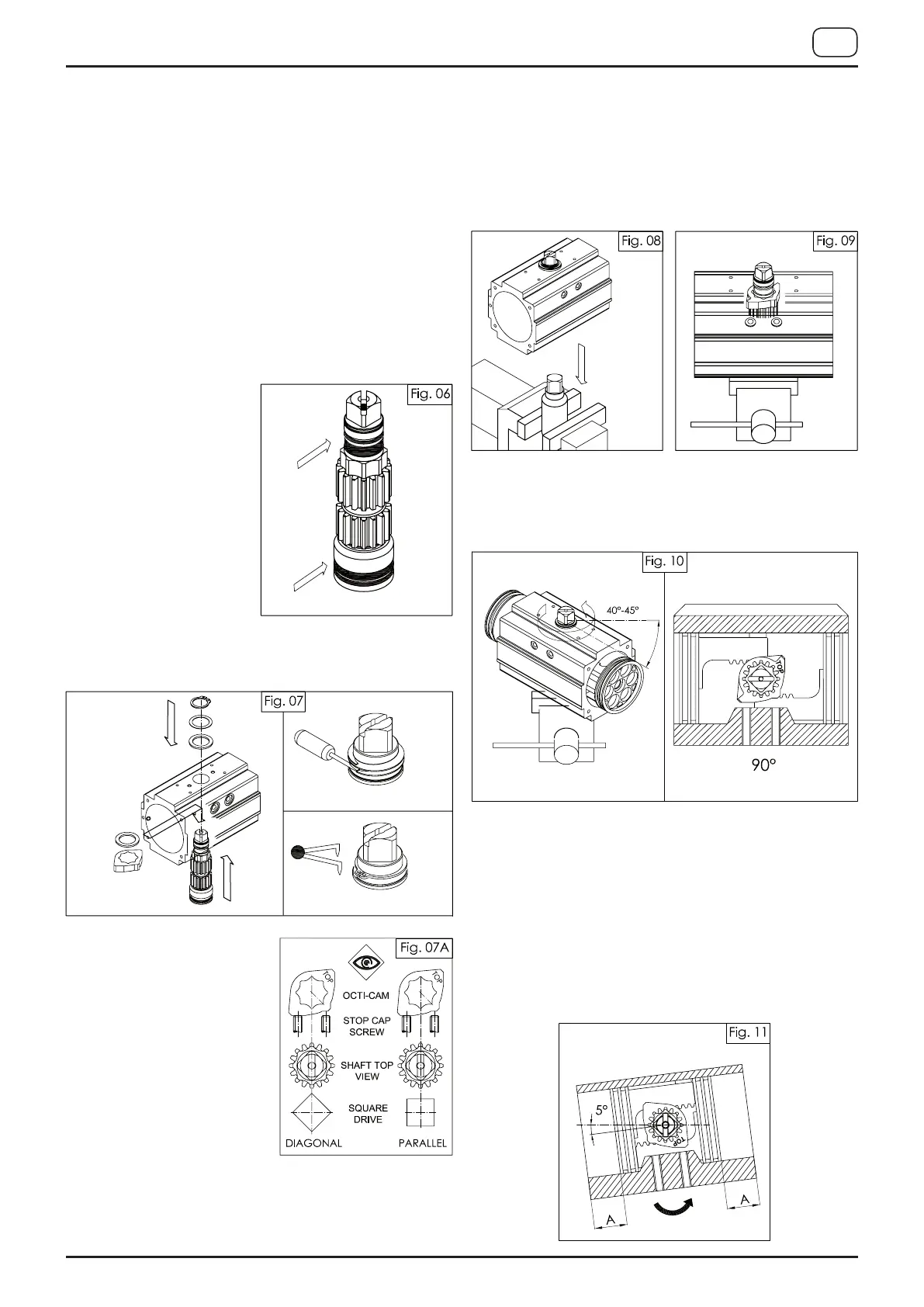

B) Pistons assembly (Part N° 40), figures 08, 09, 10 and 11:

• Grease and install o-rings (16), piston back (05) and pis-

ton head (15) bearings.

• Grease the internal surface of the body (50) and the pis-

ton (40) rack teeth.

• Insert the female connection of the drive shaft (60) in a

properly fixed coupling.

• Ensure that the octi-cam is in the right position as shown

in figure 09.

• For standard rotation assembly type “ST” (clockwise

to close), rotate the body (50) about 40-45° clockwise

from top view, as shown in figure 10.

• Insert and press the two pistons (40) simultaneously

inside the body (50) until the pistons are engaged, then

rotate the body anticlockwise from top view until the

stroke is completed.

• Ensure that with pistons completely closed, the rota-

tion obtained referred to the axis of the body is about

over 0° for models PT050 N→PT800 (0,5° over 0° for

PT045) and that the dimension “A” on both sides is the

same as shown in figure 11.

GB

IMAT PT- E

Loading...

Loading...