Page 24

Control

6.6 Main alarms

Once you have solved the problem that originated

the alarm, reset the alarms by pressing the ON-OFF

button.

E00 does not close the relay that signals an alarm

state (terminals 121-122)

High pressure alarm

When this alarm is activated, the control system halts

the operation of the involved refrigeration circuit and

opens the compressor’s control chain (safety against

failures). The alarm is reset manually from the control

panel when the pressure switch has been reset auto-

matically.

Low pressure alarm

When this alarm is activated, the control system halts

the operation of the involved refrigeration circuit.

The activation of this alarm is inhibited for approx.

40 seconds from start-up. The reset is automatic for

the first three times during the same hour. Upon the

fourth activation, a manual reset is required.

Antifreeze alarm

This alarm is enabled when the temperature of the

fluid leaving the evaporator drops below 4 °C. After

the activation of this alarm, the control system halts

the operation of the involved refrigeration circuit.

The reset is manual from he control panel.

External interlock alarm

When this alarm is activated, the control system halts

the operation of the unit. The reset is automatic.

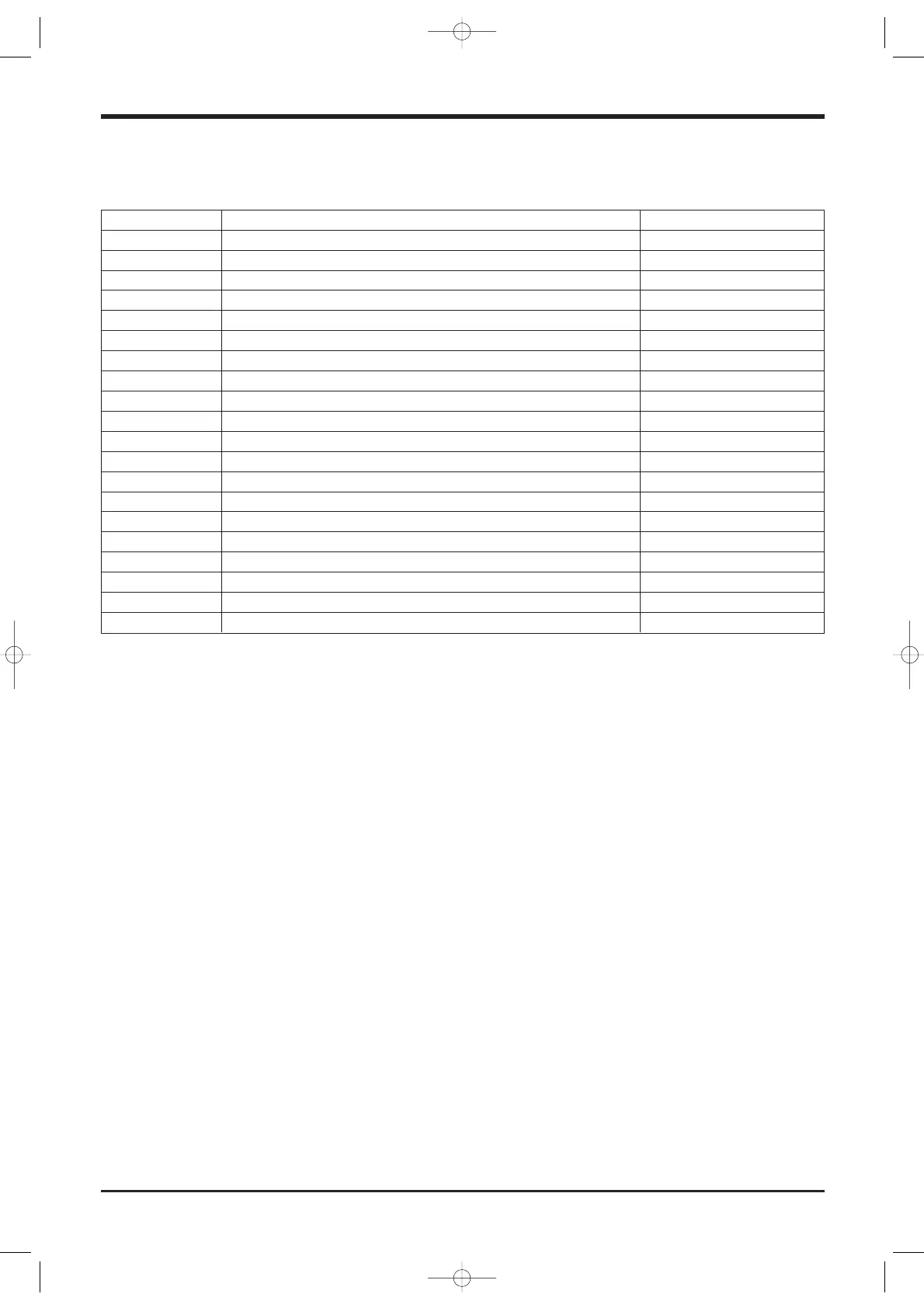

Code Description Reset

E00 Remote Off Automatic

E01 High pressure 1 Manual

E02 Low pressure 1 Automatic/manual

E03 Thermal protection, compressor 1 Manual

E04 Thermal protection, fans Manual

E05 Antifreeze, circuit 1 Manual

E06 Failure of leaving water sensor 1 Automatic

E07 Failure of coil sensor 1 Automatic

E21 High pressure 2 Manual

E22 Low pressure 2 Automatic/manual

E23 Thermal protection, compressor 2 Manual

E25 Antifreeze, circuit 2 Manual

E26 Failure of leaving water sensor 2 Automatic

E27 Failure of coil sensor 2 Automatic

E40 Failure of entering water sensor Automatic

E41 Flow meter - no water Manual

E42 Failure of ST4 sensor Automatic

E44 Machine discharge Manual

E45 Configuration error Manual

E46 High temperature of entering water Automatic