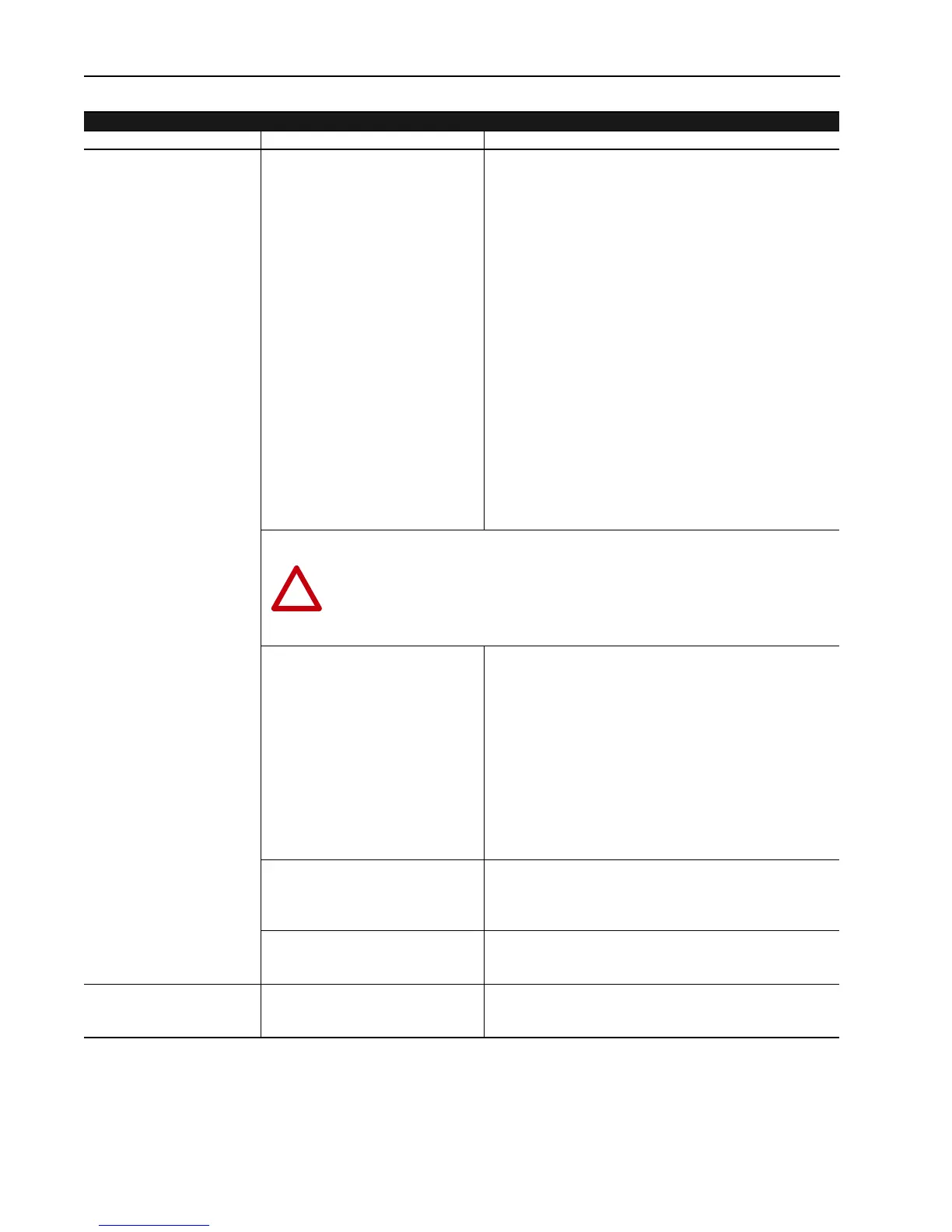

3-8 Malfunctions Not Indicated by a Fault

The motor velocity is not

controlled and excessive

velocity occurs.

The motor velocity is excessive and

parameter 106 “Velocity Fdbk” remains

constant or near zero.

• The velocity feedback device is incorrectly selected. Verify that

parameter 621 “Fdbk Device Type” reflects the proper velocity

feedback device being used.

0 = Encoder Feedback Selected

1 = Armature Voltage Feedback Selected

2 = Analog Tachometer Selected

3 = No Feedback Device Selected

• If Encoder Feedback is selected and the device has

malfunctioned, or no device is connected, or the wrong

encoder PPR is entered in Param 609, the motor will

accelerate uncontrollably and fault on VP-10 Feedback Loss.

• If Armature Voltage Feedback is selected, the motor should

only runaway if an internal component malfunctions. The

armature voltage is sensed at the DC contactor connections. It

is then scaled on the Feedback Board and measured on the

Main Control Board.

• If an analog tachometer is selected and the device has

malfunctioned or is not connected, the motor will accelerate

uncontrollably and fault. Also if the scaling is incorrect, or the

analog input signal from the tach is over voltage, the motor will

accelerate uncontrollably.

The motor accelerates uncontrollably

and parameter 106 “Velocity Fdbk” has

the wrong polarity for the direction

commanded.

• The field polarity and the direction information from the

encoder must match for proper control. Forward direction of the

motor is defined as positive armature voltage +A1/-A2 and

phase A must lead phase B of the encoder for CCW rotation as

viewed from the commutator end of the motor. Forward

direction can be defined as CW rotation by switching the

polarity of the field connections and by switching one encoder

signal pair.

• The same holds true for an analog tachometer. The polarity of

the tach signal must match the polarity of the armature voltage.

Forward rotation can be defined as either CW or CCW

depending on the polarity of both signals.

The motor accelerates uncontrollably

with the motor turning in the same

direction as the velocity command.

• Switch the encoder signal pairs or the analog tach polarity.

Then verify that parameter 107 “Position Feedback” counts up

to a higher value as the motor is rotated in the forward

direction.

The motor runs away with the motor

turning in the opposite direction as the

velocity command.

• Verify that parameter 107 “Position Feedback” counts up to a

higher value when the motor is rotated in the forward direction.

If it does, reverse the polarity of the field connections.

The motor turns at the correct

speed, but rotates in the wrong

direction.

Parameter 107 counts down to a lower

value when the motor is rotated in a

forward direction.

• Reverse both the encoder signal pairs/analog tach polarity and

the polarity of the field connections.

Velocity Control Malfunctions

Malfunction Symptom Solution

!

ATTENTION: If no Feedback Device is selected, uncontrollable acceleration of the motor

could occur. This is a potentially dangerous situation because the drive will not trip on a

Feedback Loss fault. Parameter 621 must only be set to (3) when operating the drive as

an external torque regulator in follower type applications.

Aotewell Ltd industry-mall.net

Loading...

Loading...