Rockwell Automation Publication 22C-UM001J-EN-E - January 2017 159

Application Notes Appendix D

Trim Control

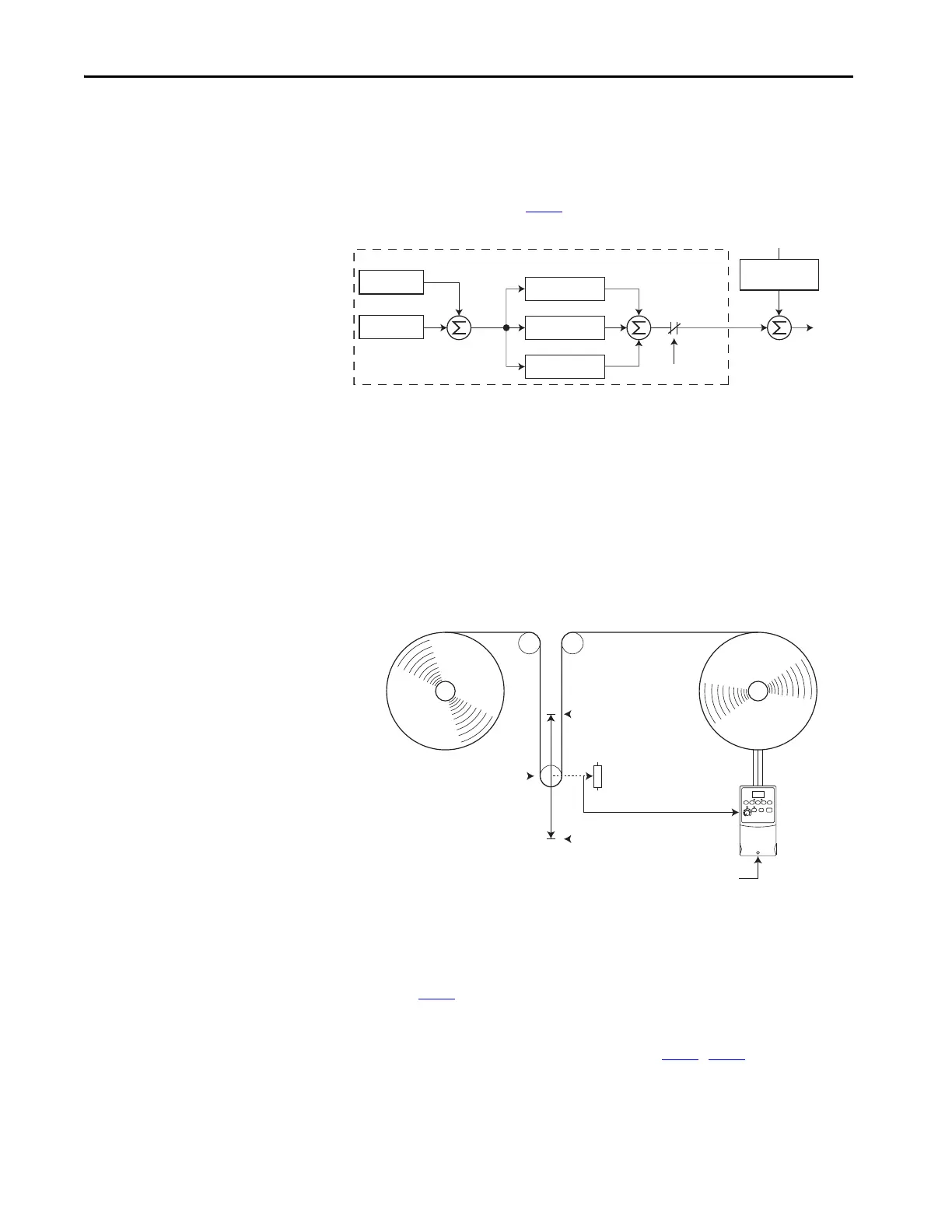

In Trim Control, the PID Output is added to the Speed Reference. In Trim

mode, the output of the PID loop bypasses the accel/decel ramp as shown.

Trim Control is used when A152

[PID Ref Sel] is set to option 5, 6, 7 or 8.

Example

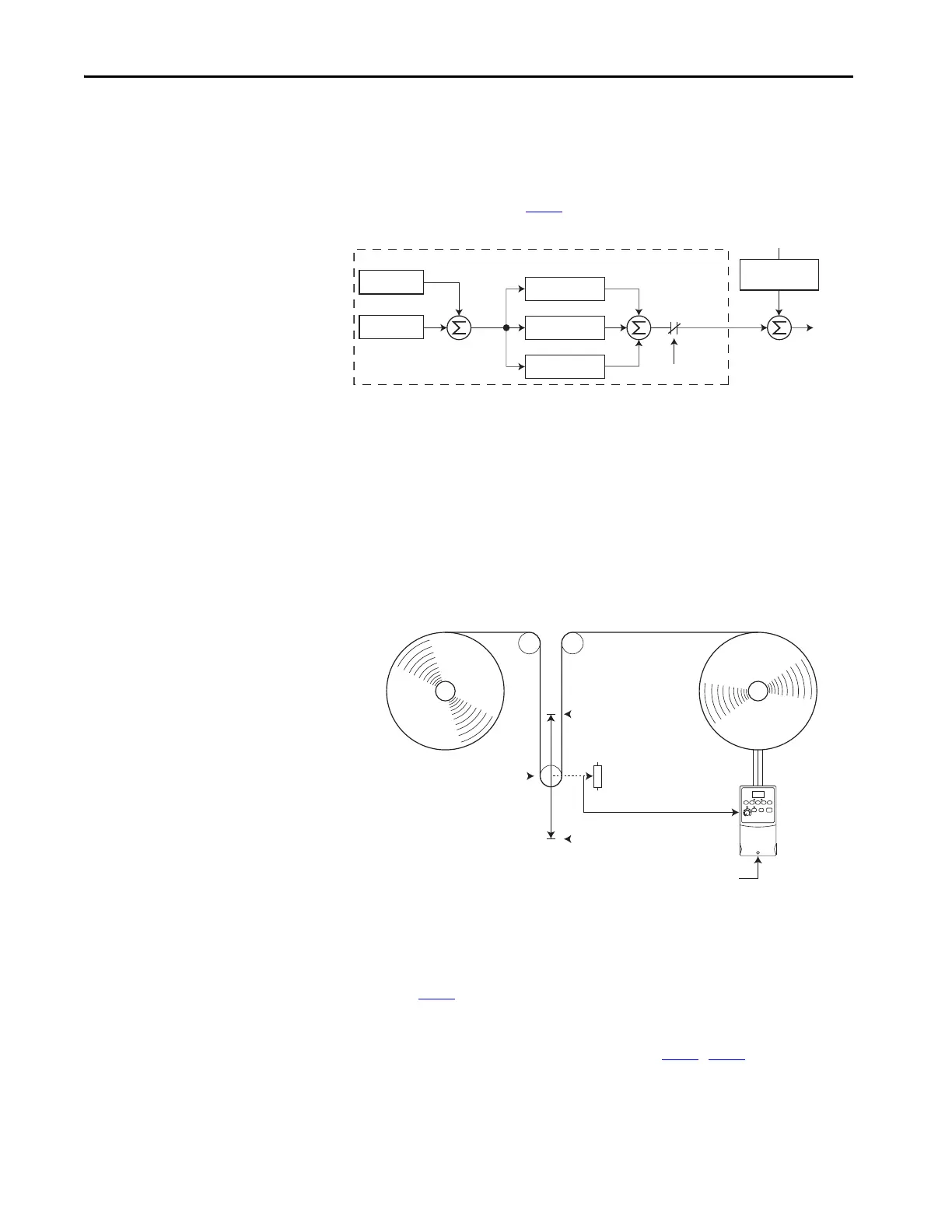

• In a winder application, the PID Reference equals the Equilibrium

set point.

• The Dancer Pot signal provides PID Feedback to the drive.

Fluctuations in tension result in a PID Error value.

• The Master Speed Reference sets the wind/unwind speed.

• As tension increases or decreases during winding, the Speed Reference is

trimmed to compensate. Tension is maintained near the Equilibrium

set point.

PID Reference and Feedback

Parameter A152 [PID Ref Sel] is used to enable the PID mode (A152 = 0

“PID Disabled”) and to select the source of the PID Reference. If A152 [PID

Ref Sel] is not set to 0 “PID Disabled”, PID can still be disabled by select

programmable digital input options (parameters T051

...T054) such as “Local”

or “PID Disable”.

–

+

PID Prop Gain

PID Loop

PID Integ Time

PID Diff Rate

PID Enabled

Speed Ref

PID Fdbk

PID Ref

PID

Error

+

+

+

+

PID

Output

Output

Freq

+

Accel/Decel

Ramp

Speed Reference

0 Volts

PID Feedback =

Dancer Pot Signal

10 Volts

PID Reference =

Equilibrium Set Point

Loading...

Loading...