25

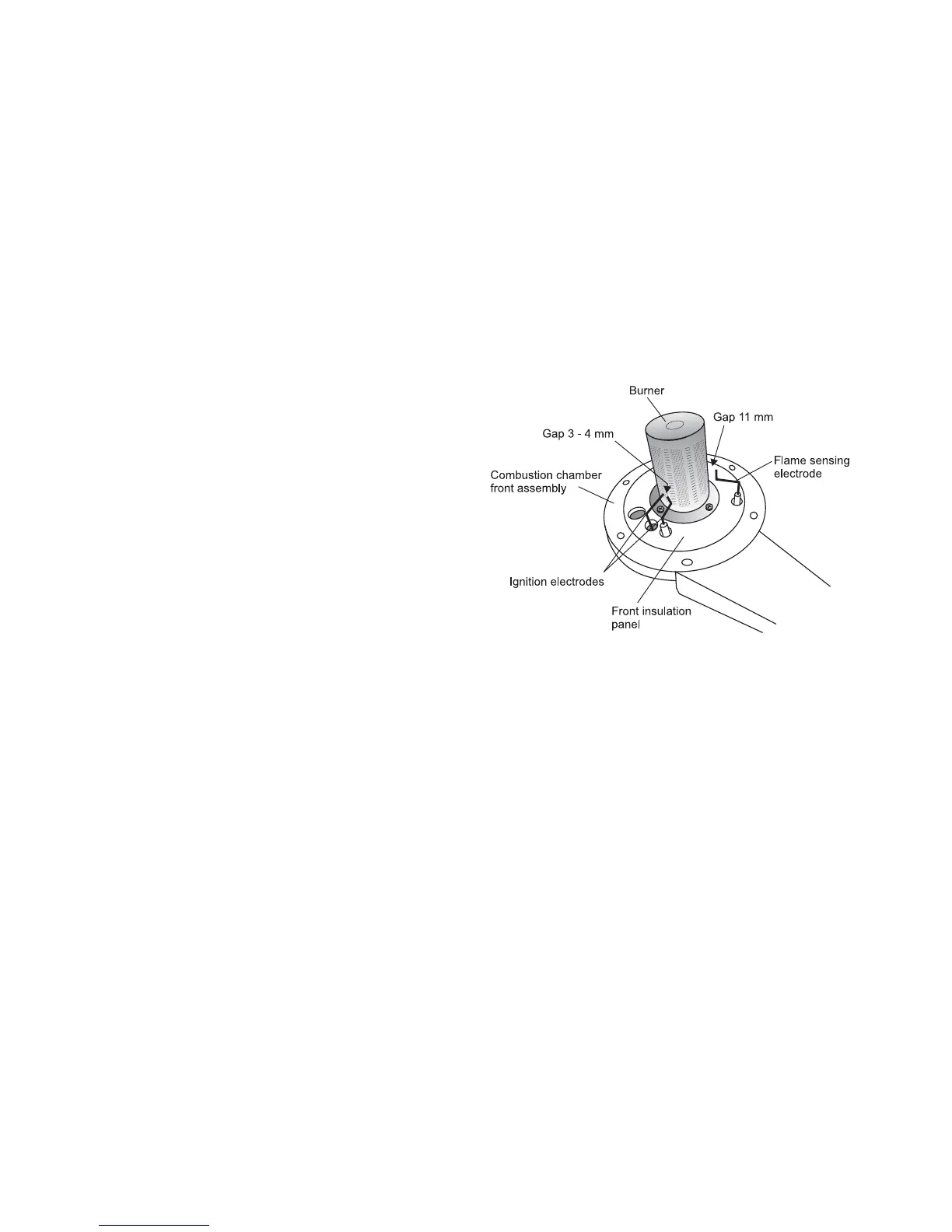

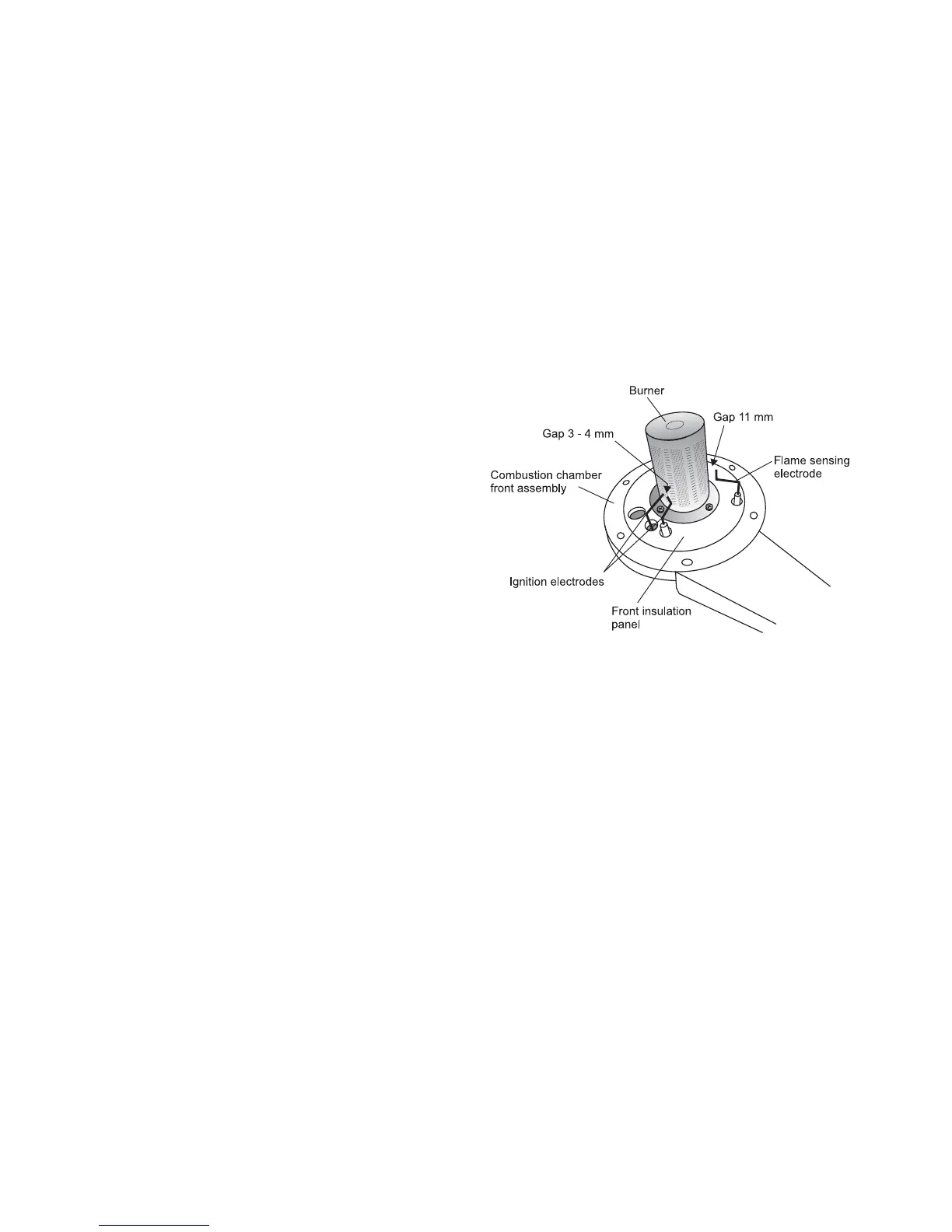

7.2 PREPARE FOR SERVICING - Fig. 27

1. Ensure the electrical supply is isolated and the gas supply is off.

2. Remove the two screws securing the bottom of the front casing. Pull the bottom forwards and remove.

3. Remove the six screws securing the front casing top bracket to both side panels and the room sealed chamber. Remove

the screw securing the CH expansion vessel.

4. Remove the two bottom screws securing the left hand side panel, lift the panel up slightly and remove.

5. Remove the three screws and release two clips securing the room sealed chamber panel and remove the panel, taking

care not to damage the seal.

6. Remove the two fixing screws (one each side) securing the control panel and hinge it forward.

7. Disconnect the gas supply pipe union.

8. Remove the two screws securing the fan assembly to the combustion chamber front.

9. Remove the two pressure tubes, noting their positions.

10. Disconnect the electrode lead from the ignition generator and the in-line connector to the flame sensing electrode.

11. Remove the six nuts and washers securing the combustion chamber front assembly and remove the assembly.

7.3 CLEANING THE BOILER

1. Remove any deposits from heat exchanger using a

suitable soft brush. Do not use a brush with metallic

bristles.

2. Check the condition of the combustion chamber

insulation panels. Any damaged panels must be

replaced. (Refer to Component Replacement, Section

8.18).

3. Check the condition of the burner injector on the

combustion chamber front assembly, carefully clean

them with a soft brush if necessary.

Do not use a brush with metallic bristles as this might

damage the injector.

4. Remove any deposits from the heat exchanger coils.

This can be done by suction or water sprayed onto the

coils. Ensure all electrical components are protected

from water. Any water used to clean the heat exchanger will drain to the condensate trap.

5. Unscrew and replace the injector if it appears damaged.

6. Remove the four screws securing the burner (see Fig. 28) and remove the burner. Clean the burner with a soft brush and

check that the flame ports are clear. Blockages may be removed with a stiffer brush. Tap the burner, open end down, to

remove any deposits from inside.

7. Check the condition of the electrodes.

9. Check the spark gap, positioning and height of the electrodes. See Fig. 28.

10. Unscrew the condensate trap drain cap (see Fig. 15) to remove any deposits.

Note: Before removing the cap, ensure that the water released from the trap can be contained to avoid spillage.

The trap will contain no more than 200 cc of condensate water. Replace the drain cap.

7.4 RE-ASSEMBLE THE BOILER

1. Replace the burner, ensuring it is located correctly and secure it in position using the four screws previously removed.

Important: Before replacing the combustion chamber front assembly, pour at least 200 cc of water into the coils of the

heat exchanger. This is to ensure the condensate trap is full of water before operating the boiler.

2. Replace the combustion chamber front assembly, ensuring it is correctly located.

3. Ensure the electrode lead is connected and the seal is in position in the bottom of the room sealed chamber.

4. Test the connections for gas soundness and re-commission, Sections 5.4 and 5.5.

5. Ensure that the room sealed chamber panel seal is intact and in position, replace the panel and secure it in position with

the clips and screws previously removed. Ensure the panel is correctly located at the rear left hand side. Replace the left

hand side case panel, securing it in place with the screws previously removed.

6. Raise the control panel and secure in position with the screws previously removed.

7. Place the front casing in position over the boiler and secure in position at the bottom using the screws previously removed.

8. Check the operation of the boiler. (Refer to Boiler Operation, Section 6).

9. Return all controls to their original settings.

Alpha CD50 - Routine Servicing

Fig. 28

Loading...

Loading...