SERVICING

66

If the pressure switch opens before the ignition period, the

induced draft blower will remain on and the control will stay in

pre-purge until the pressure switch is closed for an entire 15

second pre-purge period. The LED will flash a code of "2" to

indicate open pressure switch.

If the pressure switch opens after the gas valve has been

energized, the control will de-energize the gas valve and run

the indoor blower through the heat off delay. The inducer

stays on until the pressure switch re-closes. Then the con-

trol makes another ignition attempt.

WARNING

HIGH

VOLTAGE

D

ISCONNECT

ALL

POWER BEFORE SERVICING OR

INSTALLING THIS UNIT.

MULTIPLE POWER SOURCES MAY

BE PRESENT.

F

AILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

1. Remove wires from the electrical terminals.

2. Using a VOM check from Common to NO (Normally

Open) - should read open.

If switch reads as noted proceed to Step 3, otherwise re-

place control.

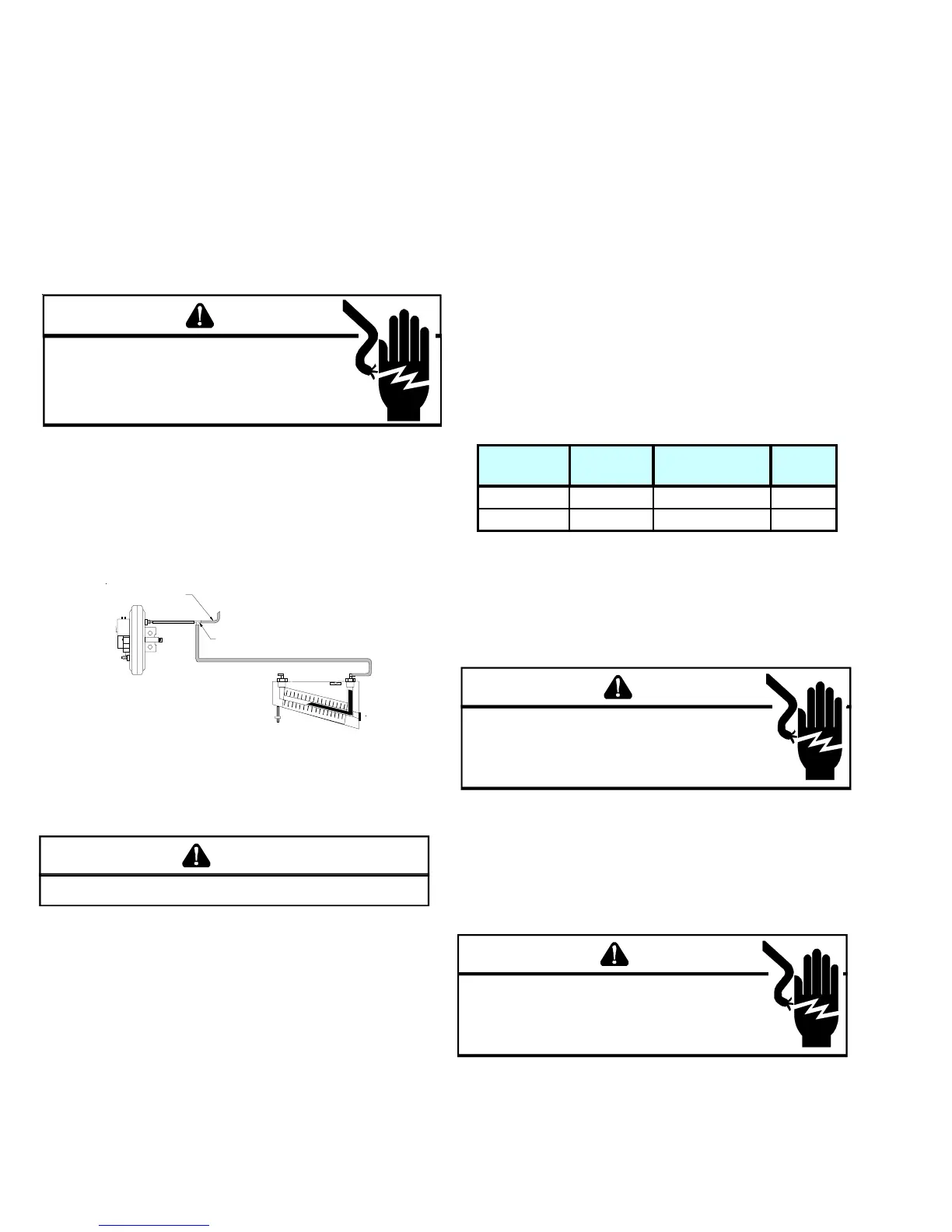

3. Remove the pressure control hose from the control and

interconnect with an inclined manometer as shown:

PRESSURE SWITCH

INCLINED

MANOMETER

1/4" COPPER TEE

HOSE

TO J-TUBE

Reconnect wires VT-18 to Common and YL-11 to NO termi-

nals.

With Power ON:

WARNING

L

INE VOLTAGE NOW PRESENT.

4. Energize furnace for heating cycle. The induced draft

blower motor will begin to run. The inclined manometer

should read approximately 1.35" W.C. negative on small

cabinets units and approximately 3.50" W.C. negative on

large cabinets with no combustion. Refer to the Product

Design section for pressure tap location.

5. Remove and check the two electrical wires and using the

VOM check from Common to NO (Normally Open), it

should read closed (with I.D. motor running). If not as

above, replace control.

6. Reconnect all wires to the control and place in heating

cycle.

7. As the unit fires, the inclined manometer negative pres-

sure will drop to -.90" W.C. for the small cabinets and -

1.90" W.C. for the large cabinets.

8. Begin to restrict the flue outlet until the pressure control

trips, cycling OFF the burner. The control will trip at ap-

proximately 0.36" W.C.negative.

9. If not as listed, replace control.

Note: the pressure switch must be mounted with the dia-

phragm in a vertical position.

S-311 HIGH ALTITUDE APPLICATION

Package units covered by this manual are approved for use

to 6,000 ft. in the USA. Canada (CSA) certified units are

approved for use to 4,500 ft. High altitude kits provide for

operation to 11,000 ft. in the USA. High altitude kits are not

approved for use in Canada. It is not necessary to change

the pressure switch for high altitude operation.

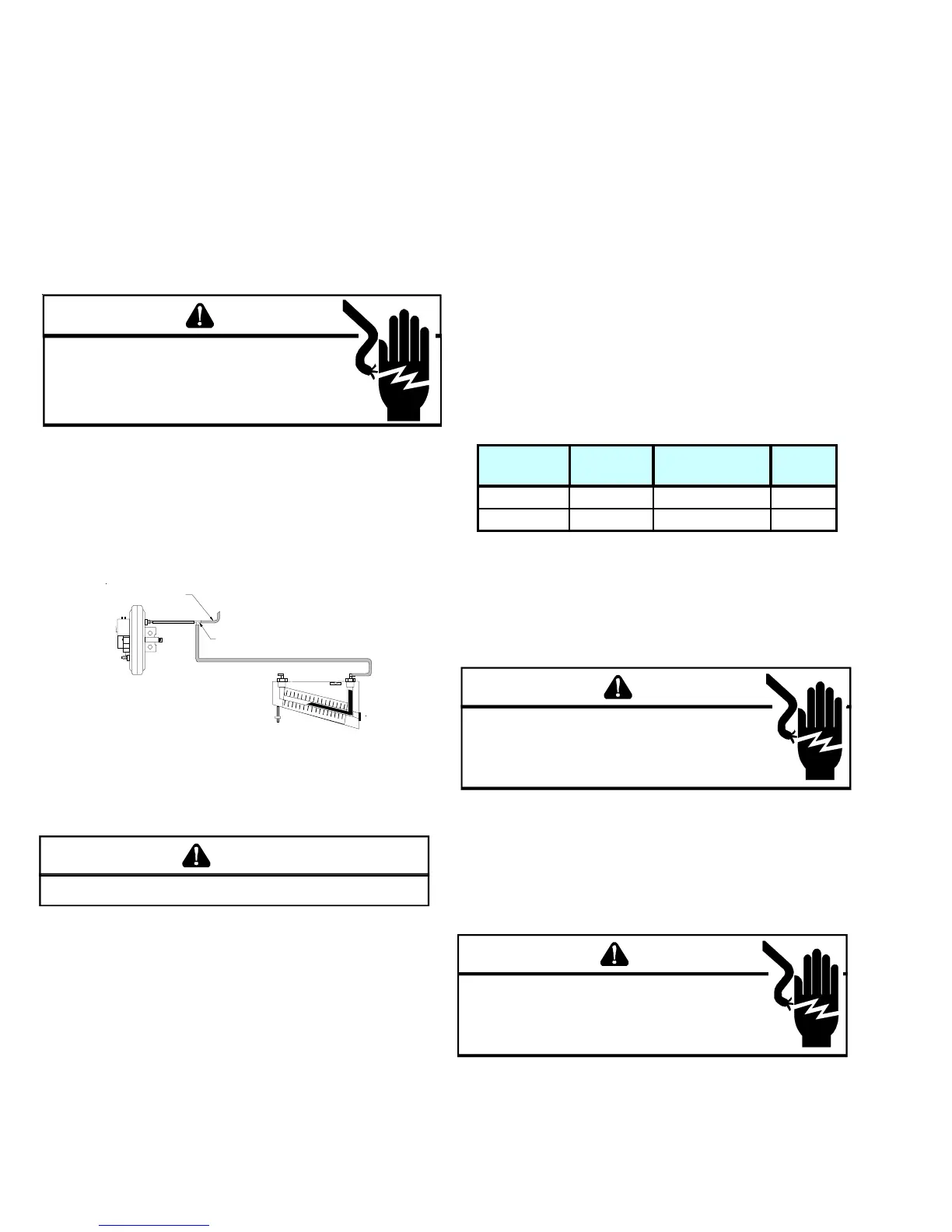

GAS

Kit

Number

Altitude

(Feet)

Orifice

NATURAL HANG07 6001 - 11000 # 45

L. P. GAS HALP09 6001 - 11000 # 56

S-313 TESTING IGNITION CONTROL MODULE

NOTE: Failure to earth ground the unit, reversing the neutral

and hot wire connection to the line (polarity), or a high resis-

tance connection in the ground or neutral lines may cause

the control to lockout due to failure to flame sense.

WARNING

T

O AVOID THE RISK OF ELECTRICAL SHOCK, WIRING TO

THE UNIT MUST BE PROPERLY POLARIZED AND GROUNDED.

DISCONNECT ALL POWER BEFORE PERFORMING SERRVICE.

M

ULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO

SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

The ground wire must run from the furnace all the way back

to the electrical panel. Proper grounding can be confirmed

by disconnecting the electrical power and measuring resis-

tance between the neutral (white) connection and the burner

closest to the flame sensor. Resistance should be less than

10 ohms.

WARNING

T

O AVOID THE RISK OF ELECTRICAL SHOCK, WIRING TO

THE UNIT MUST BE PROPERLY POLARIZED AND GROUNDED.

DISCONNECT ALL POWER BEFORE PERFORMING SERRVICE.

M

ULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO

SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

Loading...

Loading...