AMCOT ST SERIES FIBERGLASS COOLING TOWER

- 22 -

GENERAL MAINTENANCE

WATER DISTRIBUTION SYSTEM – GENERAL DATA

Sprinkler Head Identification

When attempting to identify sprinkler heads on towers that have been in service for a long time, each

sprinkler head has a factory marking, “LSH” model number, on the top of the sprinkler head. To help

with identifying your sprinkler head or potential tower model number you can refer to the table below.

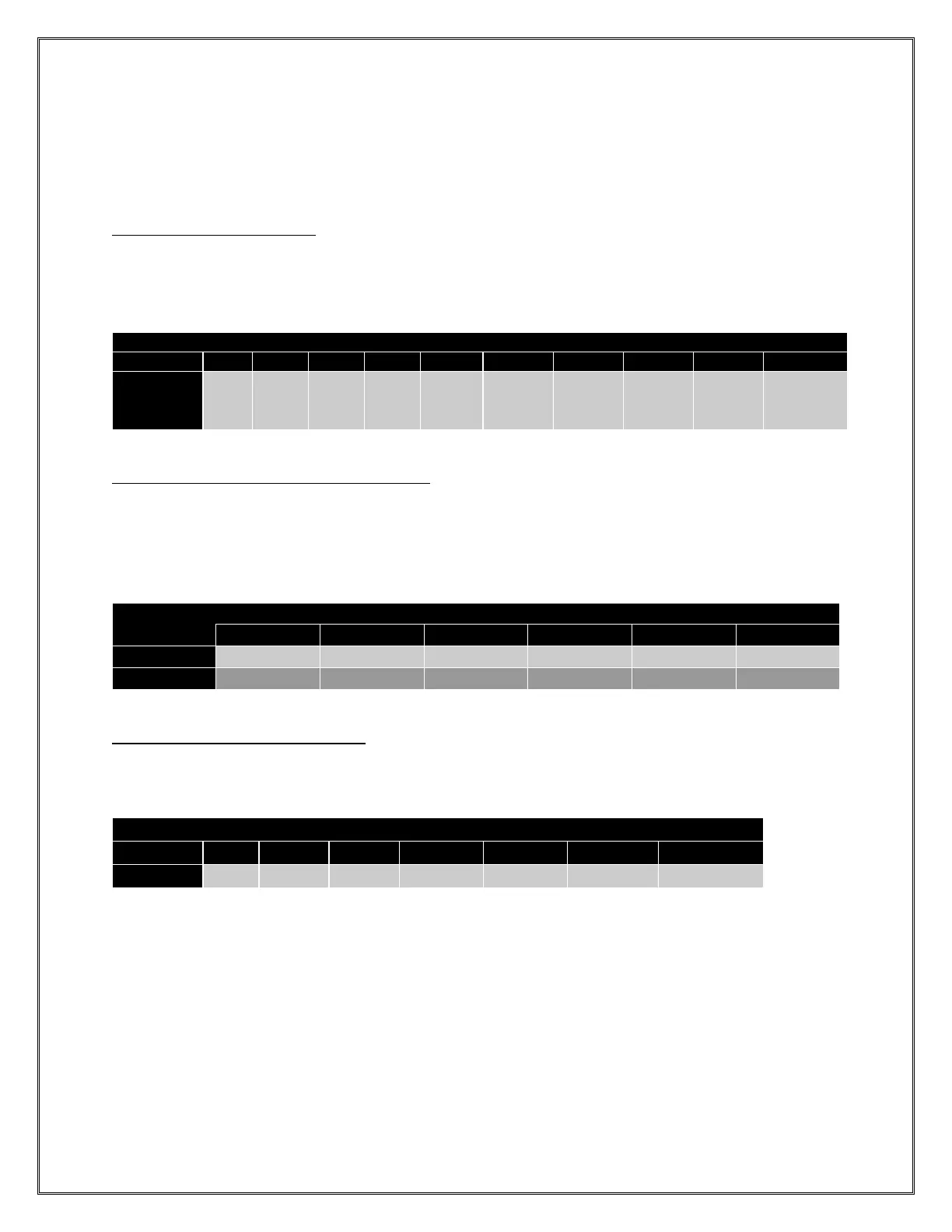

SPRINKLER HEAD REFERENCE NUMBERS

Sprinkler Head Bearings (ST-70 thru ST-1500)

For these sprinkler heads, as noted on Page 20, in some cases it may be possible for the customer or

contractor to replace the bearings which could allow you to return your unit to service faster. These

bearings can be sourced through local bearing shops and the numbers in the table below are universal

and can cross multiple manufacturers/brands of bearings.

Distribution System Rotation Speed

The speed at which the assembly rotates is based on the angle at which the sprinkler arm holes are set

at along with the water inlet pressure and the condition of the sprinkler head.

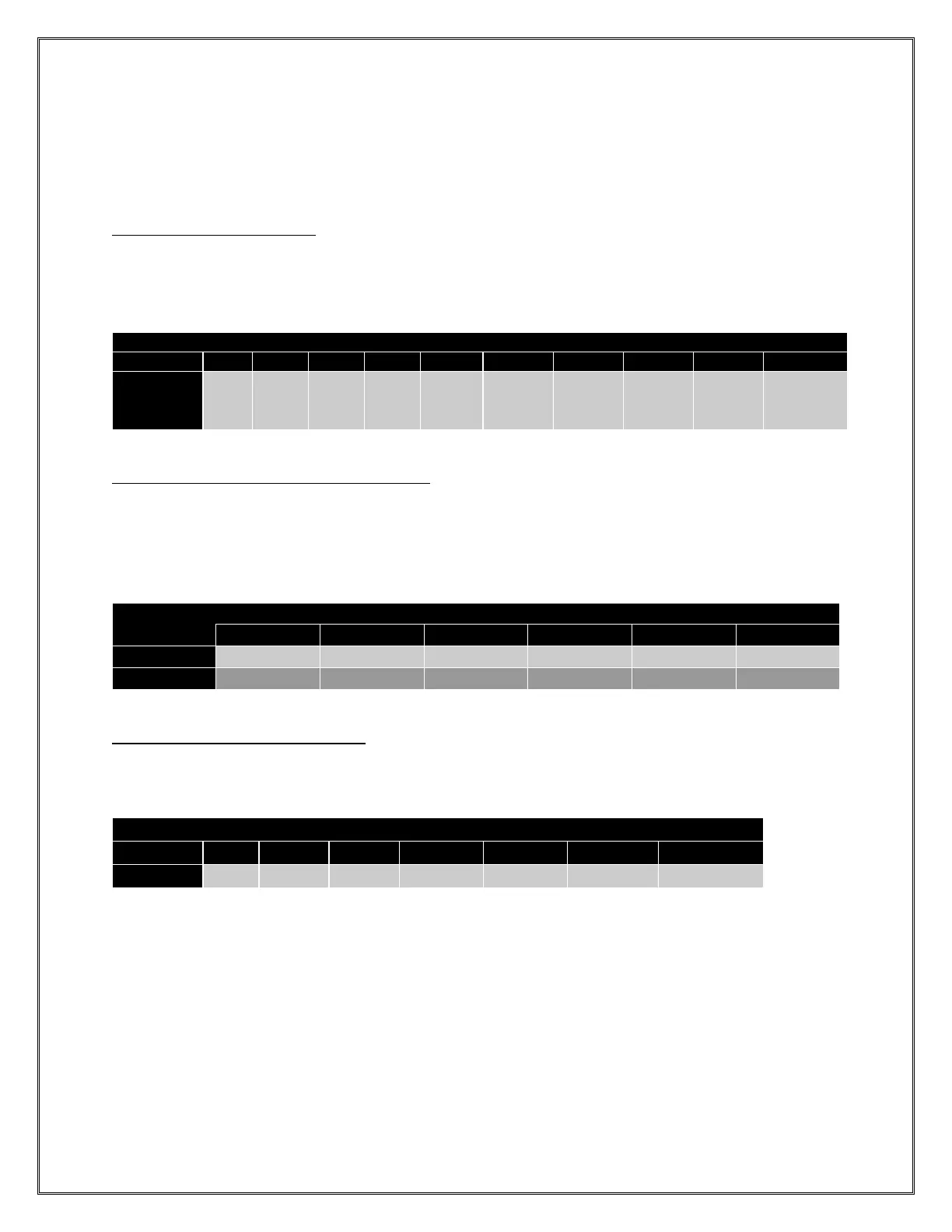

RECOMMENDED ROTATION SPEED FOR WATER DISTRIBUTION SYSTEM

If your rotation is too fast, you can slow the assembly down by rotating sprinkler arms in a clockwise

direction so that the openings where the water comes out turns slightly more towards the fill. However

if you turn them to where the openings are facing straight down, then your water distribution will fail to

rotate which is not recommended. Always test rotation speed with the fan motor running as the air

flow through the tower can cause the rotation speed to slow.

Loading...

Loading...