AMCOT ST SERIES FIBERGLASS COOLING TOWER

- 47 -

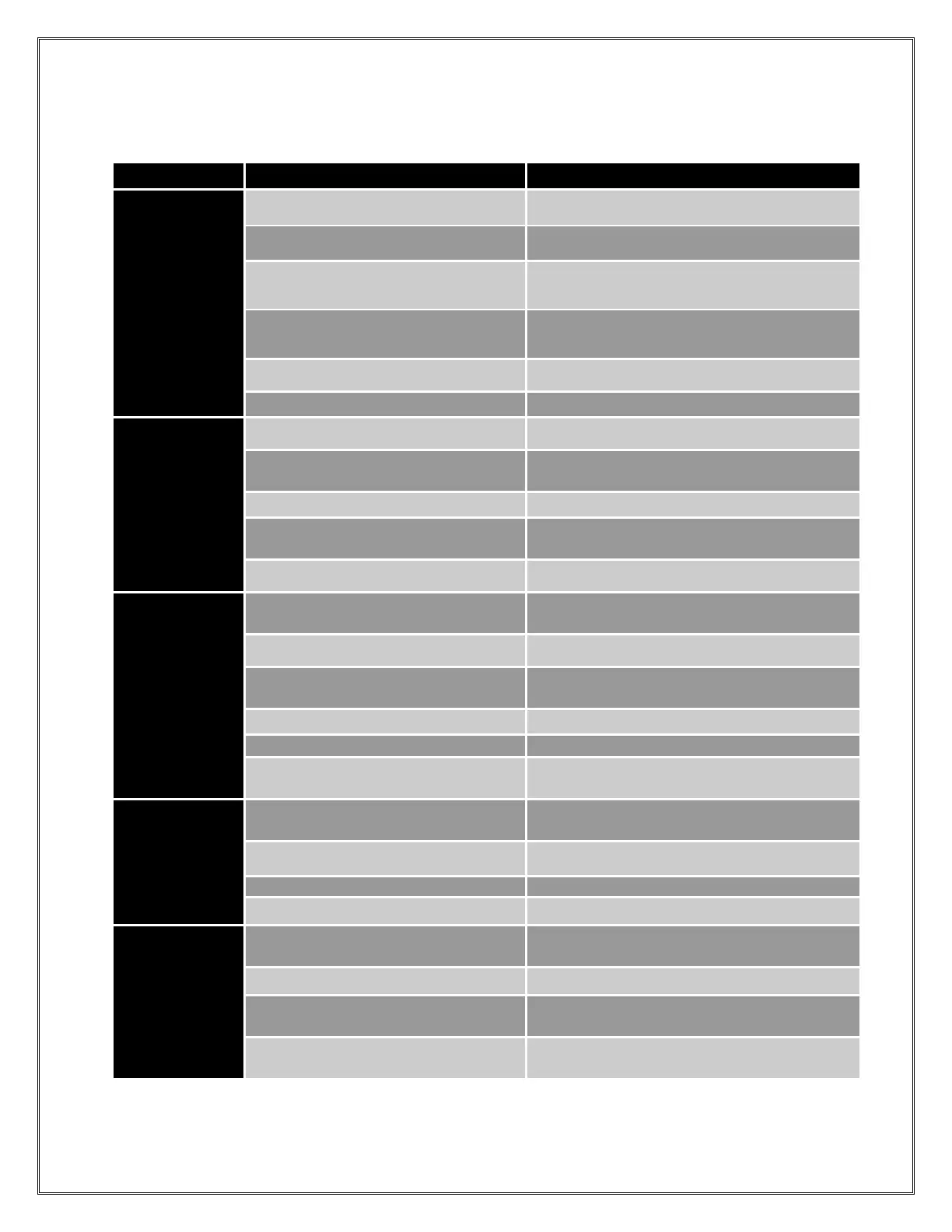

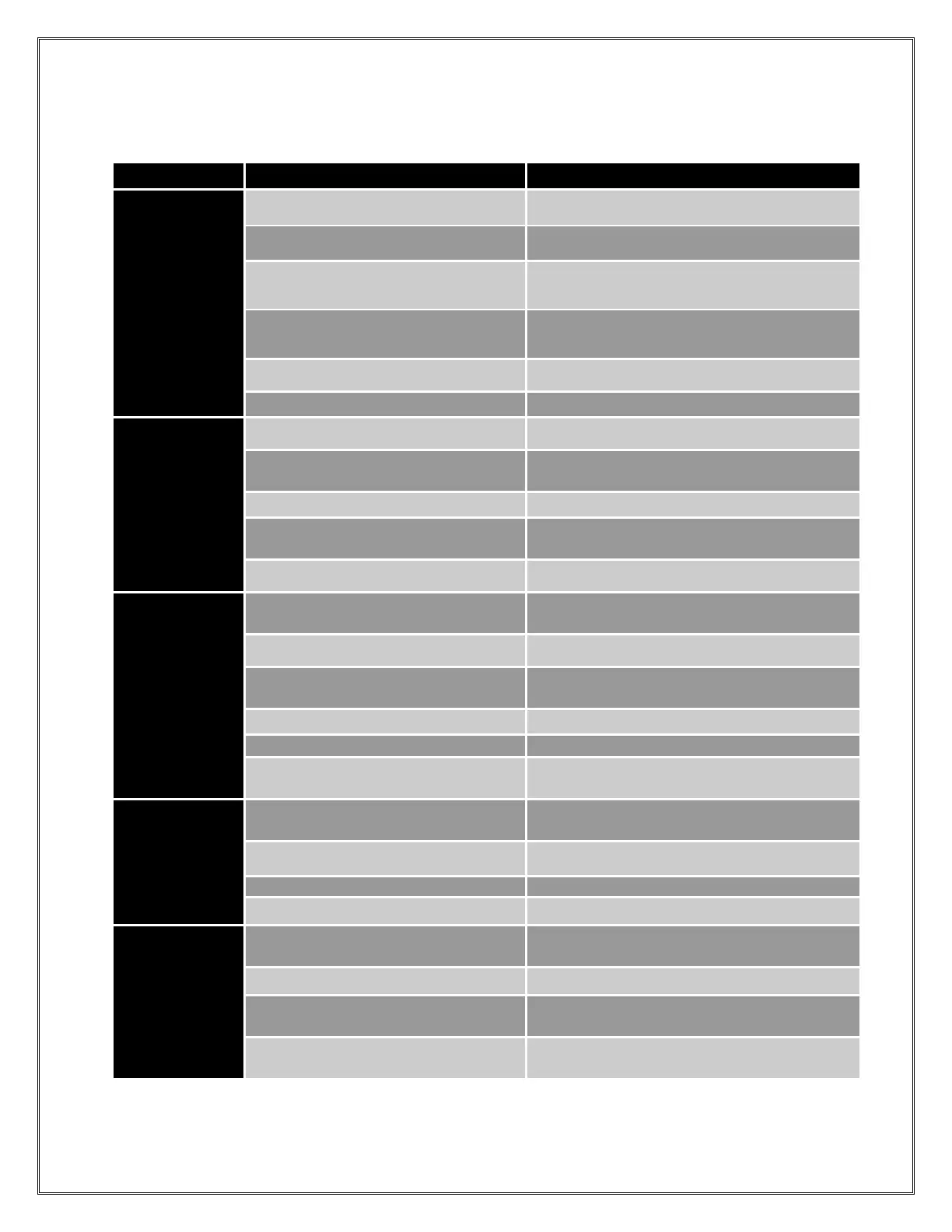

COOLING TOWER TROUBLESHOOTING GUIDE

RISE IN COLD WATER

TEMPERATURE

1. EXCESS OR LACK OF WATER FLOW

1. CHECK PIPING VALVES AND MAKE SURE DESIGN WATER

FLOW RATE IS MAINTAINED.

2. MAKE SURE EQUIPMENT AIR INTAKE IS NOT BEING

BLOCKED. IMPROVE VENTILATION.

3. RECIRCULATION OF AIR EXHAUST

3. TOP OF TOWER IS BELOW AN ADJACENT WALL OR

ENCLOSURE WHICH COULD CAUSE WARM AIR TO

RECIRCULATE. POTENTIALLY NEED TO ELEVATE TOWER.

4. IRREGULAR OPERATION OF WATER

DISTRIBUTION ASSEMBLY

4. CLEAN SPRINKLER ARMS, CHECK HOLE POSITION, MAKE

SURE NO WATER IS COMING OUT OF BASE OF SPRINKLER

HEAD.

5. CHECK AMP DRAW AND ADJUST FAN PITCH ACCORDING TO

MANUAL.

WATER

DISTRIBUTION

SYSTEM

1. SPRINKLER HEAD SEAL HAS FAILED RESULTING IN

WATER COMING OUT AT BASE OF SPRINKLER HEAD.

1. CLEAN/REPLACE SPRINKLER HEAD.

2. SPRAY ARMS NOT ROTATING WITHIN PROPER

RANGE FOR UNIT.

2. CLEAN SPRINKLER ARMS, ADJUST SPRINKLER ARM HOLES

TO ACHIEVE PROPER ROTATION.

3. CHECK VALVES EXTERNAL TO TOWER.

3. MAKE SURE VALVES ARE SET PROPERLY.

4. CHECK PUMP FOR IMPELLER/SEAL PROBLEMS OR

IMPROPER SIZING.

4. PERFORM MAINTENANCE ON PUMP.

5. CHECK STRAINERS/FILTERS

5. PERFORM MAINTENANCE/CLEANING OF BASKET STRAINERS

OR FILTERS.

1. FAN BLADE TIPS IN CONTACT WITH CASING

PANEL.

2. IMPROPER MOUNTING OF FAN BLADES

2. ADJUST PITCH ANGLE OF FAN BLADES PER MANUAL

INSTRUCTIONS.

3. CHECK BOLTS/FASTENERS ON ALL PANELS AND

MECHANICAL ASSEMBLY.

4. CHECK BELT TENSION/GREASE BEARINGS

5. MOTOR BEARING FAILURE, WILL REQUIRE REPLACEMENT

6. MECHANICAL ASSEMBLY CRACKS

6. CHECK MECHANICAL ASSEMBLY COMPONENTS FOR CRACKS

OR RUST/CORROSION. CONTACT AMCOT ASAP.

1. CHECK FAN PITCH AND ADJUST SO AMP DRAW IS AT OR

SLIGHTLY BELOW NAMEPLATE AMPERAGE.

2. POSSIBLE FILL BLOCKAGE WILL CAUSE INCREASE FAN

LOADING AND INCREASE AMP DRAW. REPLACE FILL.

3. LINE VOLTAGE FLUCTUATIONS.

3. CALL AN ELECTRICIAN TO TEST/MONITOR LINE VOLTAGE

4. MOTOR BEARING FAILURE OCCURRING

1. WATER DISTRIBUTION MALFUNCTION

1. CHECK SPRINKLER HEAD AND ARMS FOR PROPER WATER

FLOW AND ROTATION SPEED.

2. CHECK FILL MEDIA, CLEAN OR REPLACE.

3. TOO MUCH CIRCULATING WATER

3. CHECK WATER FLOW TO TOWER AND ADJUST WITH

EXTERNAL VALVES.

4. TOO MUCH AIR FLOW THROUGH UNIT

4. CHECK FAN PITCH, LOWER BLADE ANGLE TO REDUCE AIR

FLOW.

Loading...

Loading...