AMCOT ST SERIES FIBERGLASS COOLING TOWER

- 43 -

GENERAL MAINTENANCE

Mechanical Systems

V-Belt Reducers – Startup

Once the adjusting washer and adjusting gauge are correctly, positioned, reinstall the cover plate to the

reducer. Spin the fan assembly by hand a couple of times to ensure it is rotating smoothly.

Once you bring your tower online, check motor amp draw. The amp draw should be at or slightly below

the amp stated on the motor’s nameplate. If the amp draw is not, it is most likely associated with the

fan pitch and we recommend revisiting the fan assembly adjustment procedures on pages 31-33.

Check belt tension after 48 hours of operation! Afterwards, perform 3 additional adjustments at 100

operational hour intervals, and then once per month.

V-Belt Reducers – Grease

There are two (2) grease nipples located on the reducer assembly. One is located inside of the gear

reducer housing located on the intermediate shaft assembly. The other is located on the reducer’s

output shaft. It is recommended that 2-3 pumps of grease be administered to each fitting once per

quarter or following seasonal shutdowns.

The recommended grease for Amcot ST Series LBM Reducers is SKF LGMT 3 General Purpose

Industrial and Automotive Lubricant

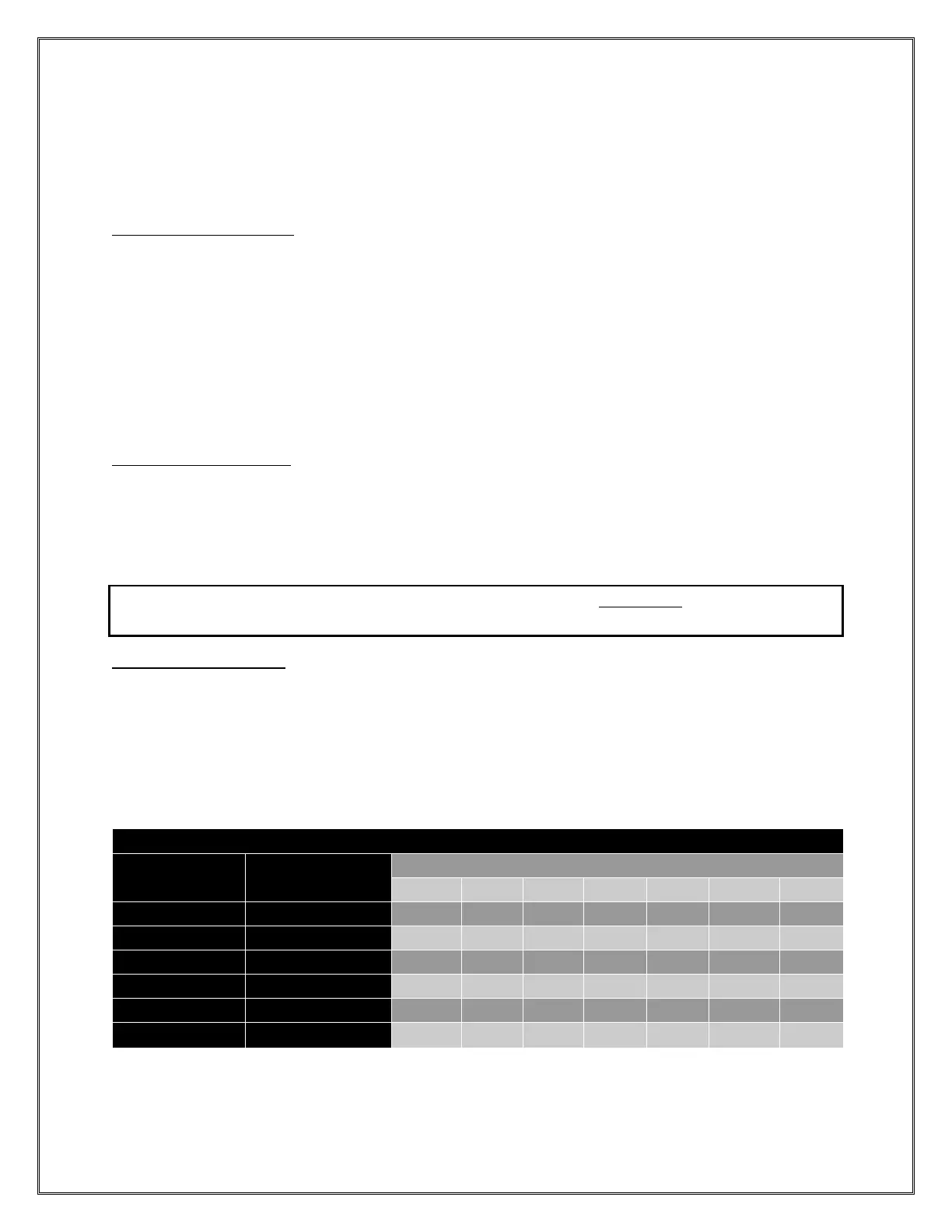

BEARING REPLACEMENT

This procedure should only be performed by an experienced mechanical contractor or mechanic whom

has experience in repair of gear drives, transmissions, or engines. The replacement of bearings can be

quite extensive and time consuming. Please refer to the V-belt diagram for the location of the various

bearings.

Below is a list of the Bearings found on the various Reducers and ST Series models ST-200 to ST-1500.

BEARING TABLE; ST V-BELT REDUCERS; LBM TYPE

Loading...

Loading...