Plunger Pumps

Operating Instructions and Parts Manual RSV Series Pumps

First Choice When Quality Matters

NORTH

AMERICA

Form RSV-OM 0607

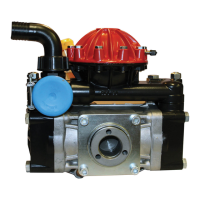

Description

Plunger Pumps are designed for a wide variety of high

pressure washing applications. They are constructed

with die-cast bodies and feature a brass head. Internal

components include coated ceramic plungers for long life

and durability. Precision cast cooling fins are anodized for

maximum heat dissipation. Oversized needle bearings on the

drive side, and ball on the non-drive side together with the

precision supports assure positive alignment and centering

in relation to the crankcase. Valve cages of special designed

Ultra-Form provide positive seating and extended life. One-

piece connecting rods are special alloy aluminum, bronze

rods over 4,000 psi units, oversized for strength and load

disbursement. These pumps are designed for gasoline driven

systems.

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

Operating Instructions and Parts Manual RSV Series Pumps

RSV 3400 rpm D Version - 3/4”

Model Max GPM Max PSI

RSV2.5G25D-F25 2.5 2500

RSV3G25D-F25 3 2500

RSV 3400 rpm D Version - 1”

Model Max GPM Max PSI

RSV3G35D-F40 3 3500

RSV3.5G35D-F40 3.5 3500

RSV4G40D-F40 4 3000

RSV4G40D-F40 4 4000

Figure 1

Hollow Shaft

Figure 2

Hollow Shaft