1

SUPER

AVC-R

Super Actuator Valve Controller

Type

- R

1.

lulroductioll

Thank

you

for

purcliasing

the

A'PEXi

Super A

VC-R.

This

is

a

highly

efficient boost

controUer

excelling

in

rapid boost response and stability.

This

'unit

can

be installed

on

virtually

any

turbo vehicle ranging

from

nomlal

engines

to hard tuned

engines

with

its self-learning

function. Furthermore, the standard

real

time

boost pressure

display

and

real

time

injector pulse

display

have

been

included

in

this

unit.

Please

be

sure

to

read this

manual

completely

and

use

the

ullit

properly.

2.

!W

ARNlNGS - Please be sure

10

read-

• Although this

unit

may

be installed on virtually

any

turbo vehicle ranging

from

normal.

modified

engines.

to

turbo upgrades, the

unit

utilizes the injector

signal

for

its self learning function

which

limits

its usage

to

Electronically Controlled

Fuel

Injection System

Vehicles

Running

On

Gasoline.

Please be aware

that

the Self- Learning

mode

cannot have

an

accurate reading irthe injector pulse

display does not

work

and if the installation vehicle

has

an

electrical current controller for the

injector

signal.

(For instance: I'Z 3 1 ,

It

31

)

"

This

unit

may

be

programmed

up

to a

maximum

boost pressure of2.0 ( kglcm2.) Raising the

boost pressure above

normal

settings

which

exceeds the

vehicle's

fuel

supply

margin

lIIay

lead

to

engine

failure.

When

raising boost pressure, please raise the boost according to the margins

of

the

injector, air

flow

meter, and

fuel

pump

of

the engine

and

turbo .

• Please be warned that

our

t'ompally

is

1I0t

respollsible for ANY damages incurred

to

the

engine, turbo alld all I'elated

cOlllllOllents

due

to

IInnecessary alld excessive boost pres!llJre

levels. •

"

Some

vehicles

may

have

a

fuel

cut

system

when

the boost pressure

has

been raised. Please

release

the

fuel

cut

system

in

these

cases.

Please contact our

company

if there are

lIny

problems

releasing the

fuel

cut

system.

• Please

use

extra caution

when

proceeding

with

wiring or

pilling

procedures. olli· cOlllpany

is

1101

responsible for any vehicle trouble resulting from falllty blstallaHoll.

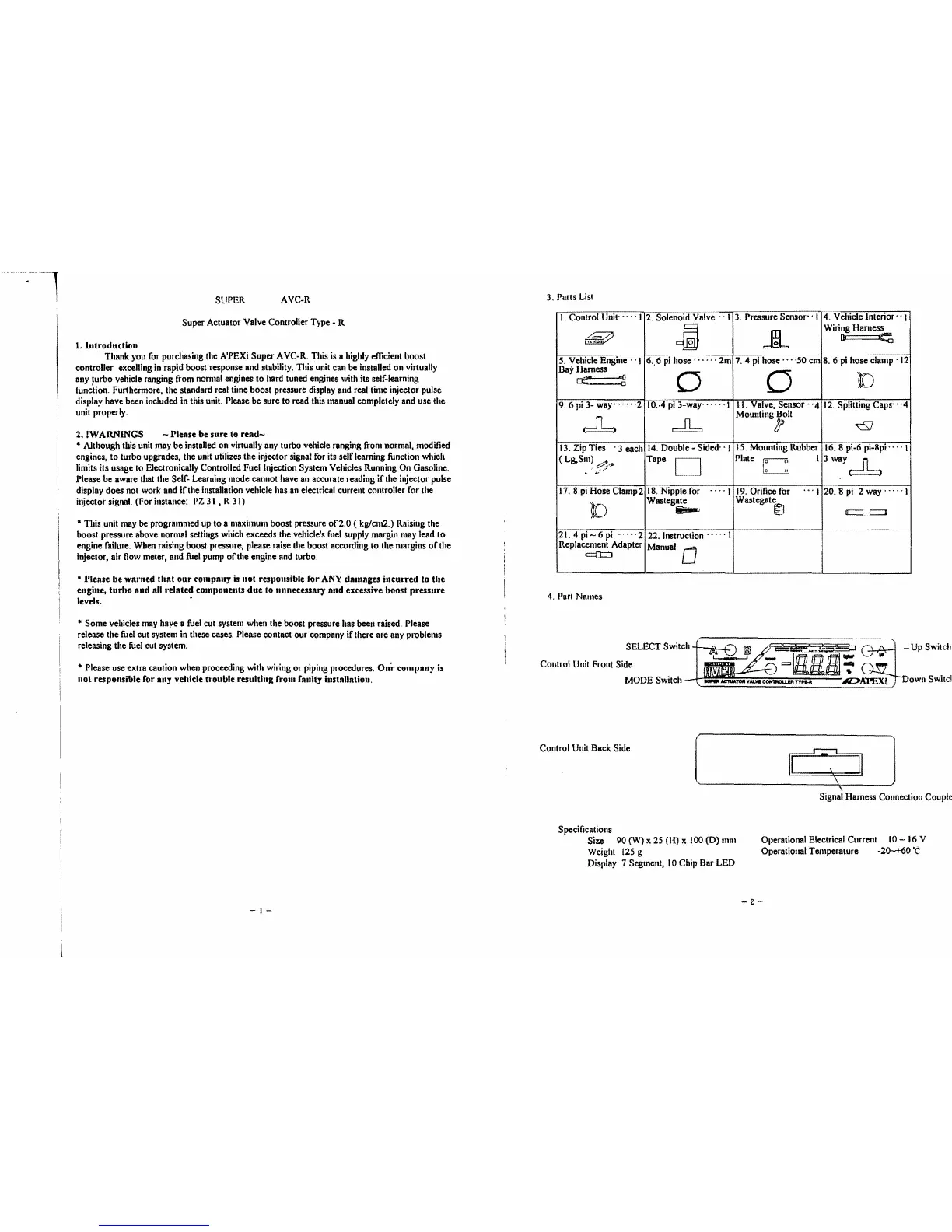

3.

Parts

List

I. Control

Unit·

....

I

4.

Vehicle Interior' . I

Wiring Harness

3.

Pressure Sensor-' 1

2.

SolenoiifValve . -I

~

[ll

~

..HL

8.6

pi

hose

clamp

'12

Bay

Harness

5.

Vehicle Engine' '1 6

..

6

pi

hose······

2m

7.4

pi

hose'"

·50

cm

[)

Cf!"----ii

0

0

9.

6

pi

3- way'

....

·2

10

...

fpi

3-way-

..

-.

'1

II.

Valve.

Sensor

-'4

12.

Splitting Caps'-

Moullting Bolt

,

<::SJ

16.

8pi-6 pi-Spi' -

_.

I

(

Lg,SIII)

/~.,

IS. Mounting Rubber

13. Zip Ties

. 3

each

14.

Double - Sided' . 1

Plate

Tape

13Wl.ly~

..

,

..

;:,:::.

...

\

20.

8

pi

2 way'

....

I

Wastegate

18.

Nipple

for

.... \

17.

8

pi

Hose Clamp2

19.

Orifice for

Wastegate

....

[)

~l

~l

o:::::::::!J=J

21.4pi-6pi

-····2

22.

Instruction

.....

\

Replacement Adapter

Manual

0

c:::(J:::l

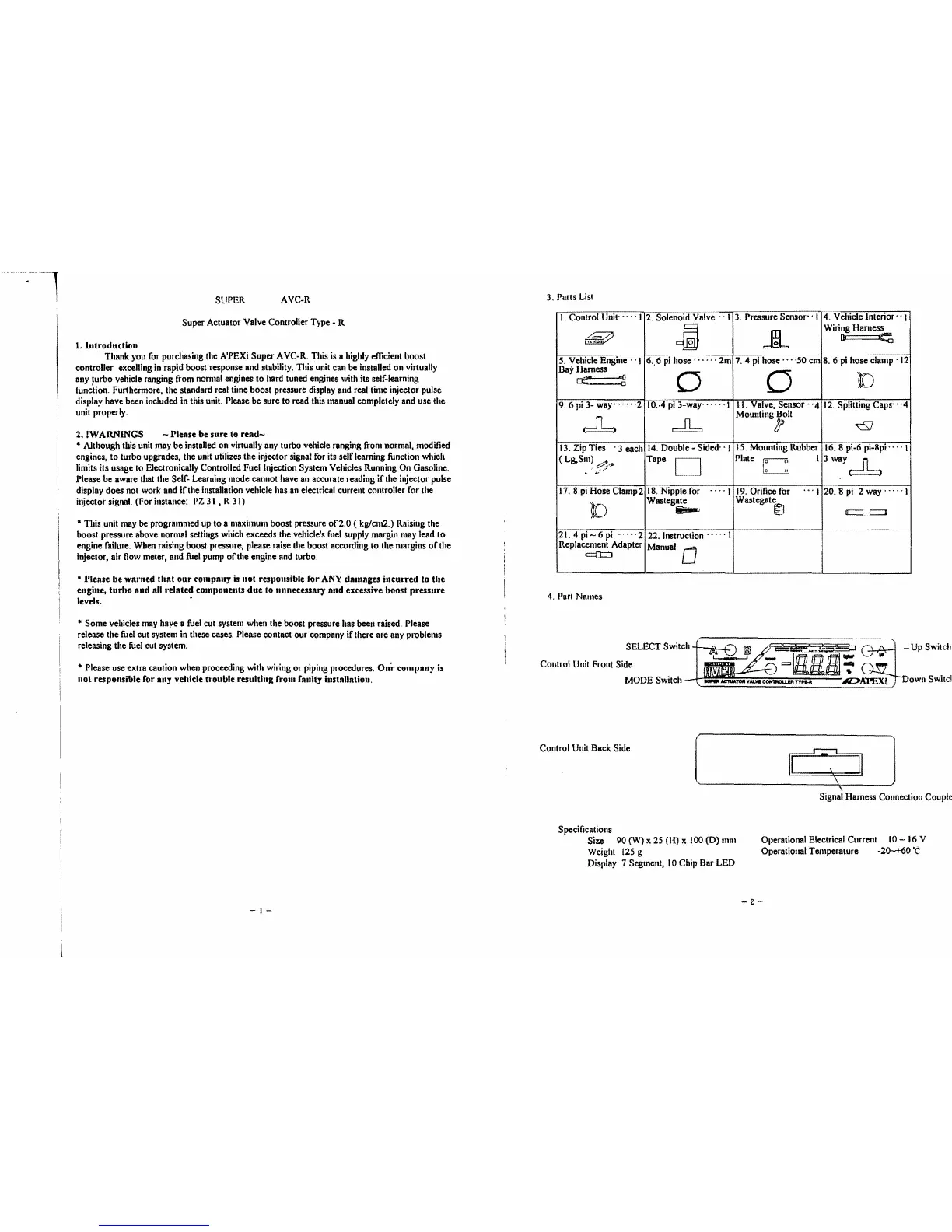

4.

ParI

Names

SELECT Switch..c.:

II

.t:\

fi'Il

~.

.Jl

....

§5:J

!.:::I

/\

1

Up

Switch

Control

Unit

Front Side

~

1IC:IIo/t;l!olt::¥d

--~--

••.

-.

Down

Switci

-t

MODE

Switch

Control

Unit

Back

Side

[

GJ]

Signal

Harness Connection Couple

Specifications

Size

90

(W)

x

25

(H) x

100

(D)

mill

Ollerational Electrical Current

10

-

16

V

Weight

125

g

Operational Temperature -20-+60'C

Display

7 Segment,

10

Chip

Bar

LED

-2-

1-

Loading...

Loading...