-1

5.

Froduct

Main

Features

..

Boost response is extremely fast.

...

Excels

in

stabilizing boost levels. ( Especially

in

higher RPM's)

...

2 Mode boost preset function

...

Self -learning function maximizes use

of

a highly efficient CPU

...

Achieves a level

of

perfect management

of

RPM specific boost management

by

combining the

injector signal with the RPM signal.

* Applies the best suited boost control even under high RPM levels .

...

Utilizes a wide- range absolute pressure sensor which accommodates high boost settings and

changes in the air pressure.

...

Includes a high precision real time boost display and injector pulse display along with a digital

and bar graph display. (Includes a maximum injector pulse indicator)

...

For extra safety, a preset boost locking feature is included.

(set-up)

..

Easy

to

mount 1/4 DIN case size.

6. Inslnilation

Frocedures

!

Cautioll

..

Please be sure that the engine has fully cooled down before attempting any piping installation.

..

Please be sure to disconnect the negative terminal

of

the battery before attempting any wiring

installation .

...

Please mount this unit away from direct sunlight.

..

Please mount this unit where the driver cannot reach. ( Approximately

SO

cm away from the

drivers seal)

LIJ

Fundnmentnl

Filling

I,

Actuator

TYlle

1.

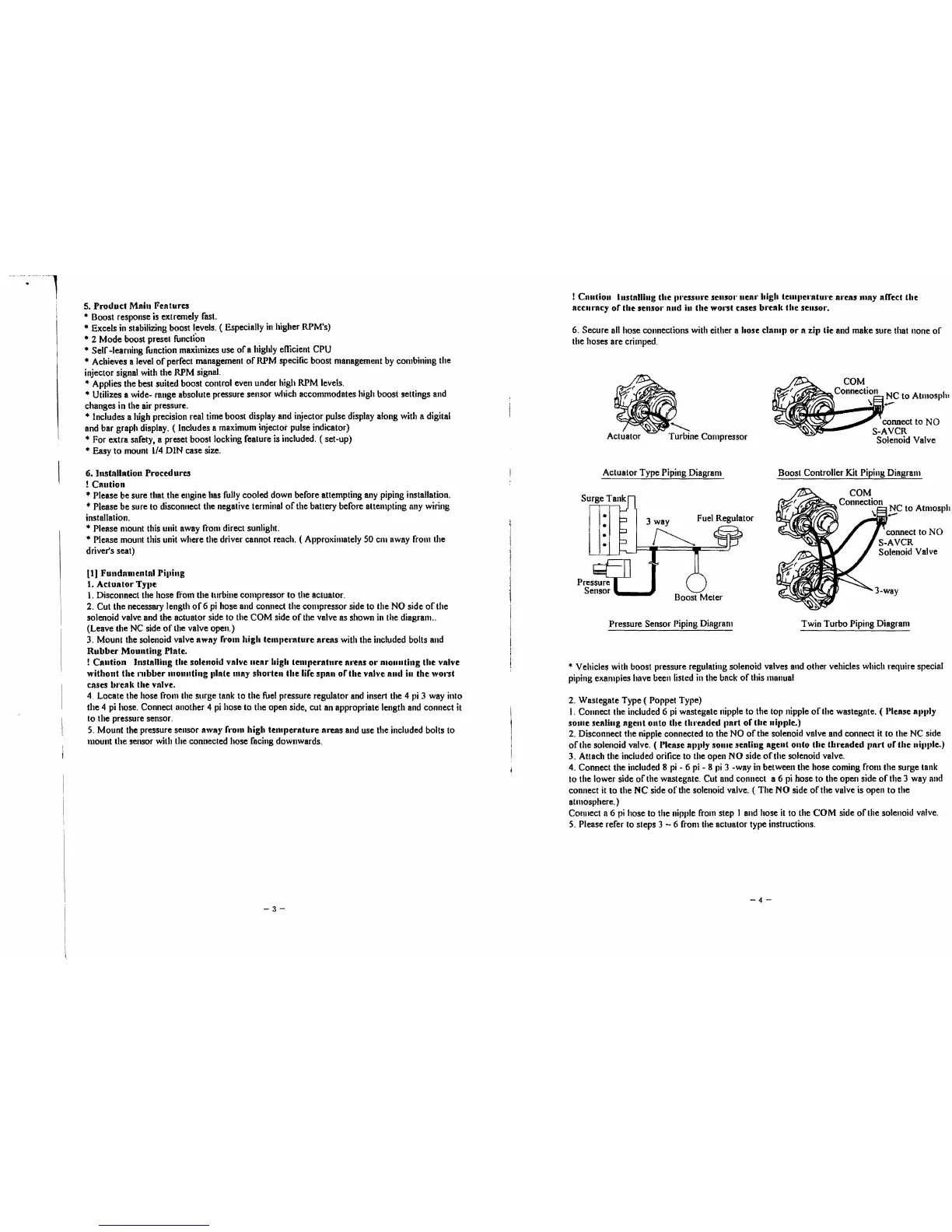

Discollnectthe hose from the turbine compressor to the actuator.

2. Cut the necessary length

of

6

pi

hose and connect the compressor side

to

the NO side

of

the

solenoid valve and the actuator side to the COM side

of

the valve as shown

in

the diagralll

..

(Leave the

NC

side

of

the valve open.)

3. Mount the solenoid valve away rrolll high telllllelllture

areas

with the included bolts and

Rubber

Mounting

Flate.

!

Cantion

Installing the solenoid valve

near

high

temperature

areas

or

monnting

the

valve

withont

the

I1Ibber mOllnting Idate lIIay shol'ten

the

life

span

or

the valve

and

in the

wont

cnses

break

the valve.

4. Locate the hose

frOI1l

the surge tank to the

fuel

pressure regulator

and

insert the 4

pi

3 way into

the 4 pi hose. Connect another 4

pi

hose

to

the open side, cut an appropriate length

and

connect it

to

the pressure sensor.

5.

Mount the pressure sensor nwny

fl"olll

high

tempernture

nreas and use the included bolts to

Illount the sensor with the connected hose facing downwards.

-3-

!

Cantion

Installing

the

III'esslIl"e

senSUI"

neal" high tellll,el"atUl"e al'eas lIIay affect

the

accuracy

or

the

sensol'

aud

in

the

WOl'St

cases bl"enl'

the

SenSOI",

6. Secure all hose connections with either a hose

clamp

or

n zip tie and make sure that none

of

the hoses

are

crimped .

NC to Atmosplu

~

?:nnecttoNO

fi.'\

S-AVCR

Solenoid Valve

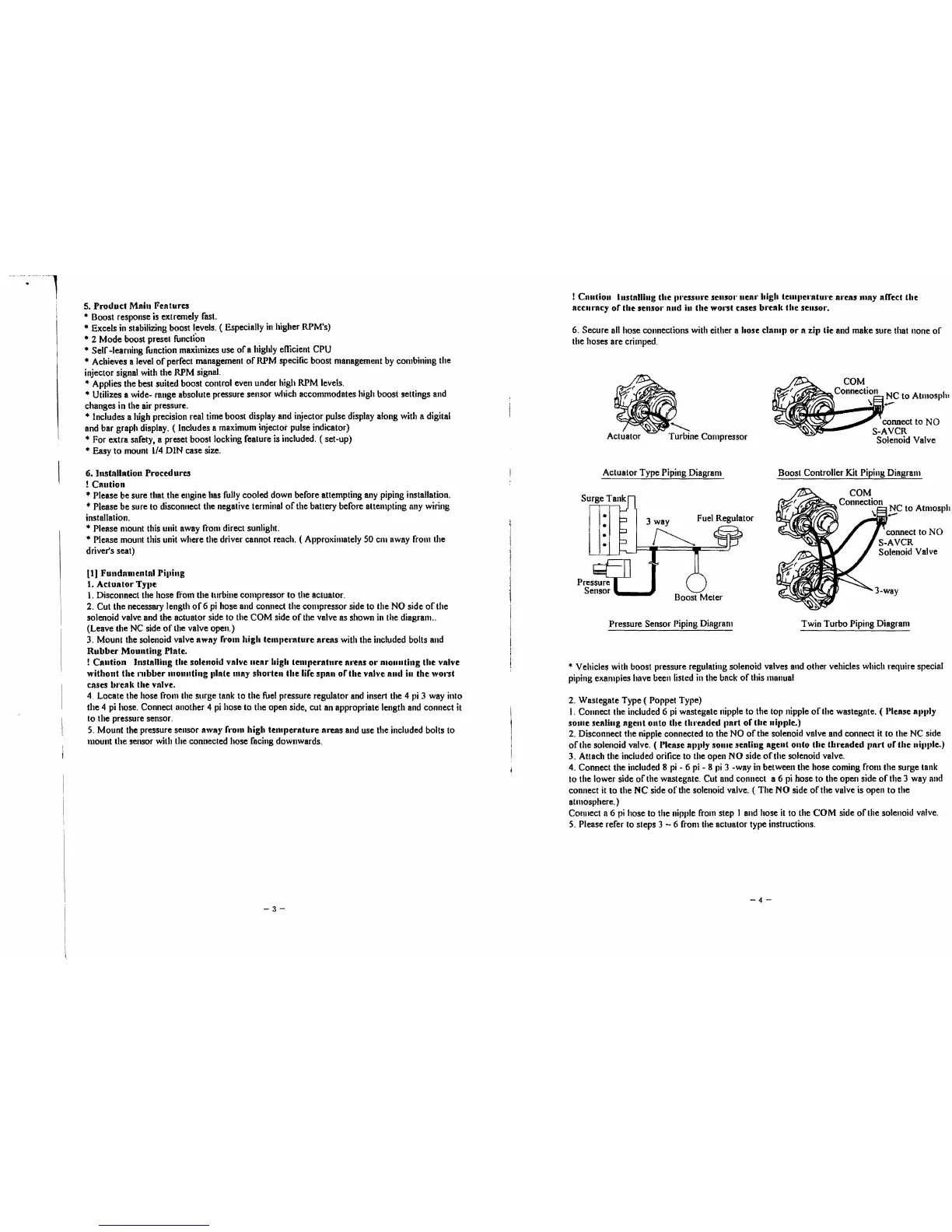

Actuator Type Piping Diagram Boost Controller Kit Piping Diagram

COM

Connection NC to Atl1losph

\13-

Pressure Sensor Piping Diagram Twin Turbo Piping Diagram

..

Vehicles with boost pressure regulating solenoid valves and other vehicles which require special

piping examples have been listed

in

the back

or

this manual

2. Wastegate Type ( Poppet Type)

I.

Connect the included 6

pi

wastegate nipple to the top nipple

of

the wastegate. ( l'lease allilly

sOllie sealing

agent

onto

the tlll"eaded Ilart

of

the

nipple.)

2,

Disconnect the nipple connected to the NO

of

the solenoid valve and connect it

to

the NC side

of

the solenoid valve. ( I'lease n"I"Y

SOllie

sealing agent

OlltO

the

thl"eaded

part

ur

the

lIi"I,le.)

3. Attach the included orifice

to

the open

NO

side

ofthe

solenoid valve.

4. Connect the included

8

pi

- 6 pi - 8

pi

3 -way

in

between the hose coming froll! the surge tank

to

the lower side

of

tile w8stegate. Cut and connect a 6

pi

hose

to

the open side

orthe

3 way and

connect

it

to

the

NC

side

of

the solenoid valve. ( The

NO

side

or

the valve is open to the

atmosphere. )

COllnect a 6

pi

hose to the nipple

froll!

step I and hose

it

to the

COM

side

orthe

solenoid valve.

S.

Please rerer to steps 3 - 6 from the actuator type instructions.

4-

Loading...

Loading...