292930

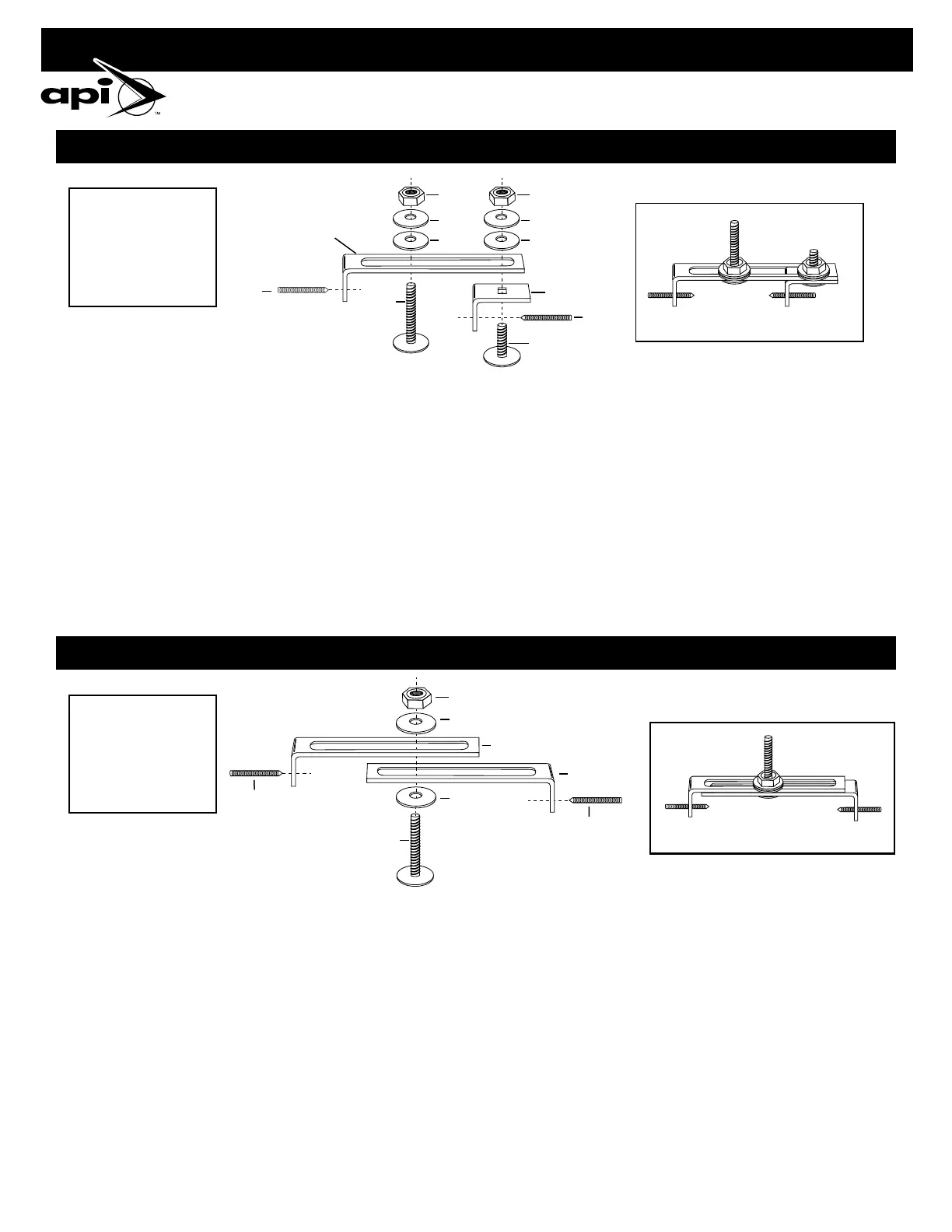

HEATED 20” BIRD BATH

Item # 600

Miller Manufacturing, Glencoe, MN 55336 USA • www.miller-mfg.com

1. Assemble mount as shown but leave the nuts (part #L) loose enough to

allow adjustment of bracket.

2. Back out the long set screw (part #G) as far as possible out of the arm

(part #A) and out of the angle bracket (part #J).

3. Position bracket so the elevator bolt (part #H) is in the center of rail.

4. Open or close bracket by sliding angle bracket (part #J) along arm (part

#A) so that the arm (part #A) and angle bracket (part #J) are hugging

the sides of the railing.

a. If the bracket will not open large enough for the width of your railing

try the next size bracket configuration.

b. If the bracket will not close small enough for your rail, screw the set

screw (part #G) deeper into both the arm (part #A) and the angle

bracket (part #J). This will act as a spacer.

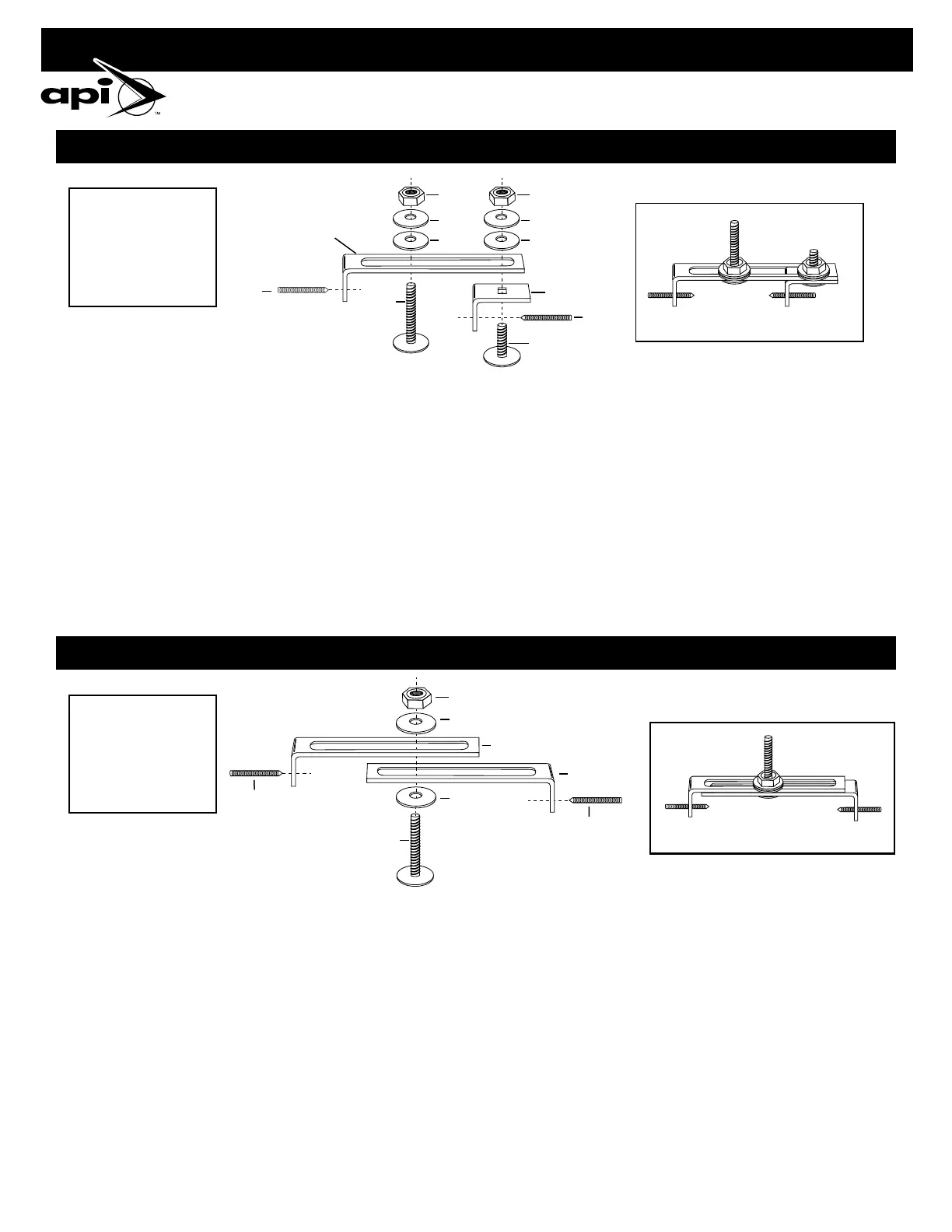

1. Assemble mount as shown but leave the nuts (part #L) loose enough to

allow adjustment of bracket.

2. Back out the long set screw (part #G) as far as possible out of both arms

(part #A).

3. Position bracket so the elevator bolt (part #H) is in the center of rail.

4. Open or close bracket by sliding angle bracket (part #A) towards each

other. Ideally so that both arms (part #A) are hugging the sides of the

railing.

a. If the bracket will not open large enough for the width of your railing

try the next size bracket configuration.

b. If the bracket will not close small enough for your rail, push the arms

together until they stop. Position the center elevator bolt (part #H) in

the center of your wooden rail. Then screw the set screws (part #G)

deeper into both the arms until the cone points on the set screws

(part #G) hit the wooden surface. This will act as a spacer.

5.

Make sure that the center bolt is in the center of the rail. Then tighten both

nuts (part #L). You must use a wrench to insure that both nuts are tight.

6. While applying pressure to the top of the mount (so the bottom surface

of the elevator bolt (part #H) is flush against the wooden surface) use a

screwdriver to tighten the two set screws (part #G). Do not over-tighten

because this will cause the mount to bend. As a rule, tighten the set

screw just past the point of the mount bending.

7. Do not be concerned if the mount assembly wobbles back and forth.

This wobble will correct itself once the bath is “spun” onto the mount

and tightened against the wooden surface.

8. Set the bath onto the center screw (part #H) and “spin” the bath into

place. It should be spun until the bottom surface of the bath rests tight

against the surface of the railing and there is no wobble.

5. Make sure that the center bolt (part #H) is in the center of the wooden

rail. Then tighten the center nut (part #L). You must use a wrench to

insure this nut is tight.

6. While applying pressure to the top of the mount (so the bottom surface

of the elevator bolt (part #H) is flush against the wooden surface) use

a screwdriver to tighten the two set screws (part #G). The set screws

should dig into the wood – but only slightly. Do not over-tighten

because this will cause the mount to bend. As a rule, tighten the set

screws just past the point of the mount bending.

7. Do not be concerned if the mount assembly wobbles back and forth.

This wobble will correct itself once the bath is “spun” onto the mount

and tightened against the wooden surface.

8. Set the bath onto the center screw (part #H) and “spin” the bath into

place. It should be spun until the bottom surface of the bath rests tight

against the surface of the railing and there is no wobble.

MOUNTING TO A METAL DECK RAILING

MOUNTING TO A WOODEN RAILING UP TO 3.5” WIDE

MOUNTING TO A WOODEN RAILING FROM 3.5” TO 8.75” WIDE

If this nut (part #L) does

not fit tight against the

washer (part #K), then

you will have to add ad-

ditional washers. Do this

until the nut fits tight.

If this nut (part #L) does

not fit tight against the

washer (part #K), then

you will have to add ad-

ditional washers. Do this

until the nut fits tight.

J

D

G

(Exploded Diagram)

L

K

H

A

G

K

L

K

K

(Finished Diagram)

(Finished Diagram)

(Exploded Diagram)

L

K

H

A

A

G

K

G

Loading...

Loading...