5609 RS 01/17

PAGE 16

©2017 4Front Engineered Solutions, Inc. - APS Resource

1

1

2

2

3

3

4

4

A A

B B

C C

D D

- CRITICAL QUALITY DIMENSION

TOLERANCES ARE IN INCHES

UNLESS OTHERWISE SPECIFIED

MATERIAL SPECIFICATION

DRAWN

MATERIAL#/PO#

PART DESCRIPTION

DRAWN DATE

JOB/REF NUMBERSCALE

ISSUEPART NUMBER

.X :

0.060

.XX :

0.030

.XXX :

0.010

FRACTIONAL :

1/16

DIAMETER : +0.015 / -0.005

ANGULAR :

1 DEG

AFORM5609-FIG16

APS 2000 SUB-ASSEMBLY

NONE

JJS 2/29/2012

UOM

INCH

The information contained herein is proprietary and confidential to 4Front Engineered Solutions, Inc. - APS Resource and is to be

used solely for the express purpose of consideration and development of the article described herein and may not be reproduced or

disseminated without the express written permission of 4Front Engineered Solutions, Inc. - APS Resource.

SHEET SHEET SIZE

C1 OF1

Your Afterma rket So lution

APS Resource

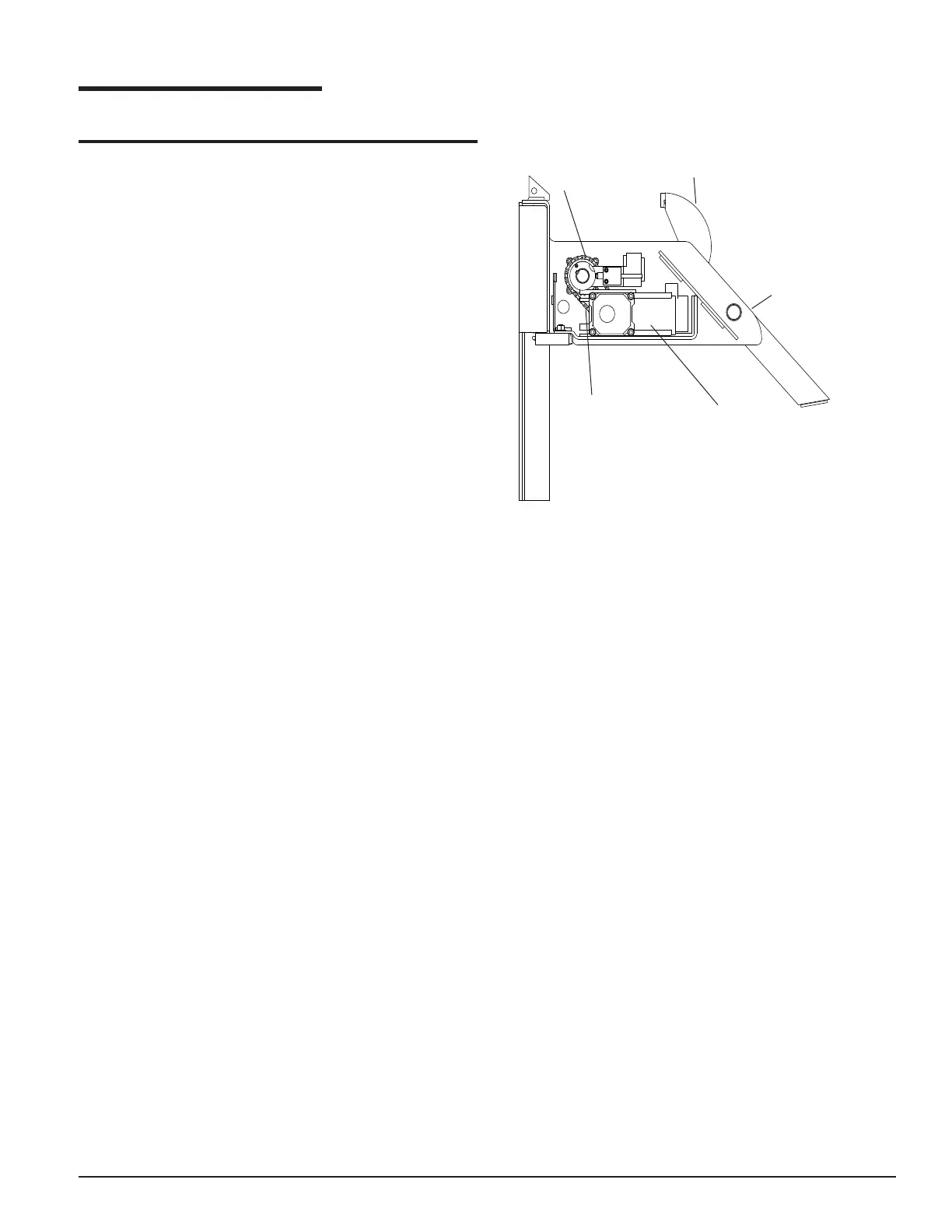

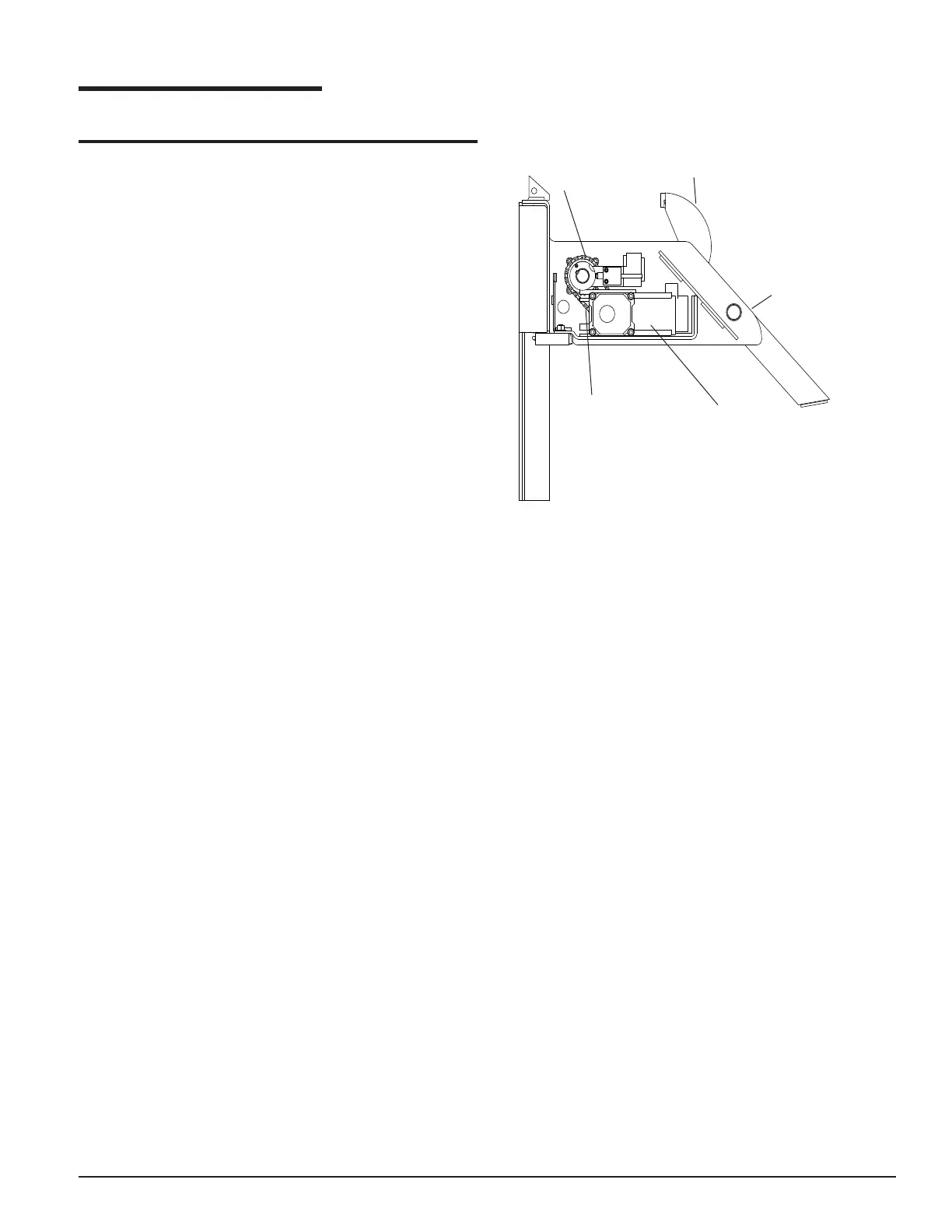

PLANNED MAINTENANCE

CHAIN ADJUSTMENT PROCEDURE

1. Move the hook to horizontal position and remove

motor cover. See Figure 18.

2. Check the drive chain slack. It should not have more

than 1/4" slack. See Figure 18.

3. If the chain needs adjustment, loosen the three nuts

on the motor mounting carriage bolts and move the

motor toward the front of the carriage. Make sure the

sprockets are in line and tighten the mounting bolts.

Recheck the slack in the chain. See Figure 18.

4. Reinstall the motor cover.

5. Turn power on and press "RELEASE" push-button to

store the hook.

FIGURE 18

MOTOR

FRONT OF

CARRIAGE

SLACK 1/8" - 1/4"

CHAIN

CHECK WITH HOOK IN

HORIZONTAL POSITION

Loading...

Loading...