GB

Form no.: L453147GB– revision 06/2013

7. Service and maintenance

7.3 Replacing the motor

ThestandardmotoroftheW+pumphasalockedfrontbearing.

Ifthemotorisreplaced,thenewmotormustalsohavealocked

frontbearing.Themotorbearingisenclosedandpermanently

lubricated.

A"smallange"(B34)forframesizesanda"largeange"(B35)in

caseoflargeconstructions.

Whenreplacingthemotor,followtheinstructionsbelow.For

thereplacementofbearings,seethemotorsupplier'sservice

instructions.

1. Switchoffthepowersupply,andthendisconnectthepumpand

motorfromthesystem.

2. Remove the pump body. See 7.2, paragraph 1-4.

3. Dismantle the impeller.

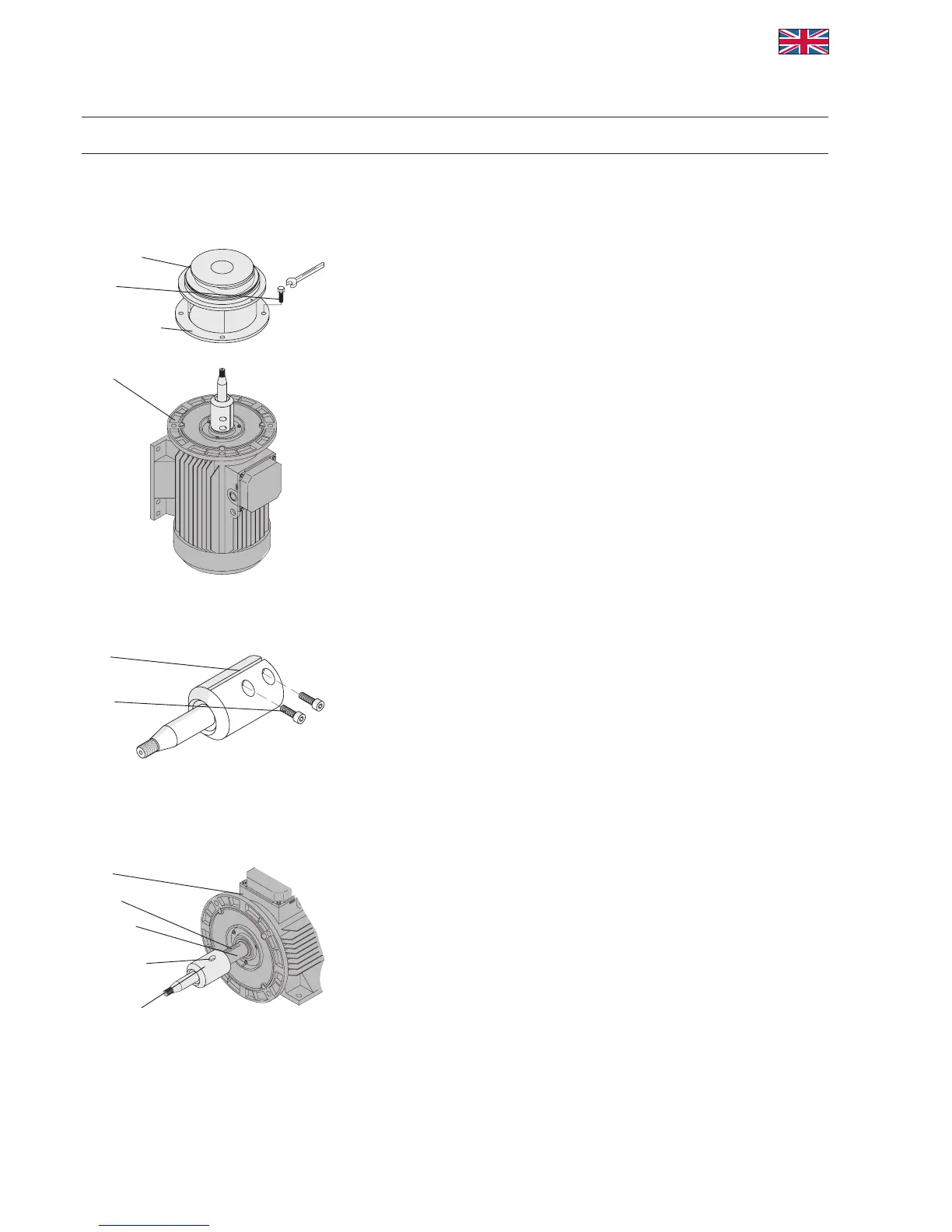

4. Removethemotorshroudand,ifpossible,placethepumpvertically

onthemotor'sfancover.Fig.7.

5. Releasethefourmotorangescrewsandremovethem(Fig.7).

6. Liftthebackplate(item7)andextensionframe(whicharestill

boltedtogether)offtheshaft.SeeFig.10.

Removethespacerange(item17)(wheretted).

7. SeeFig.8.Loosenthescrewsatthebaseoftheshaft,removethe

shaftandreplacethemotor.

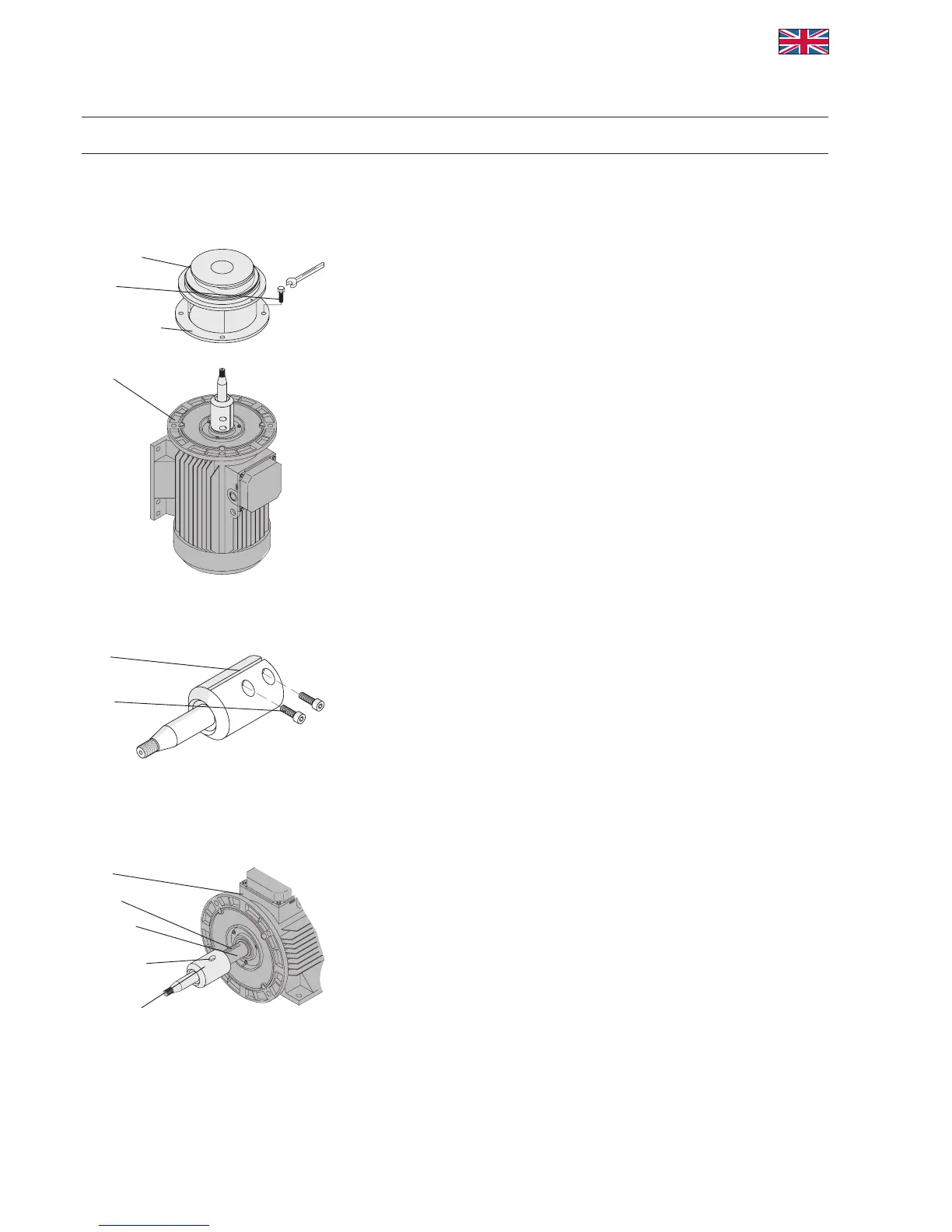

8. SeeFig.9.Beforemountingthenewpumpshaft,removeanydirt

andgreasefromthemotorshaftandthebase'sinternalclamping

surfaces.Looselymountthepumpshaft.Positionthebalancehole

overthekeyway.

9. Fitthebackplateandextensionframeovertheshaft.

10. Tighten the bolts.

11. Standthepumpbackonitslegs/brackets.

12. Fittheimpellerandsecureitwiththecapnut/inducer.

Remember to use the proper tightening torque:

M10: 45Nm(33ft-lb)

M14: 70Nm(52ft-lb)

M20: 200Nm(148ft-lb)

Fig. 7

Fig. 8

Fig. 9

Rearange

Screw

Extensionframe

Motor

Shaft

Screw

Motor

Keyway

Motorshaft

Balancehole

Pumpshaft

13

APV

Loading...

Loading...