4

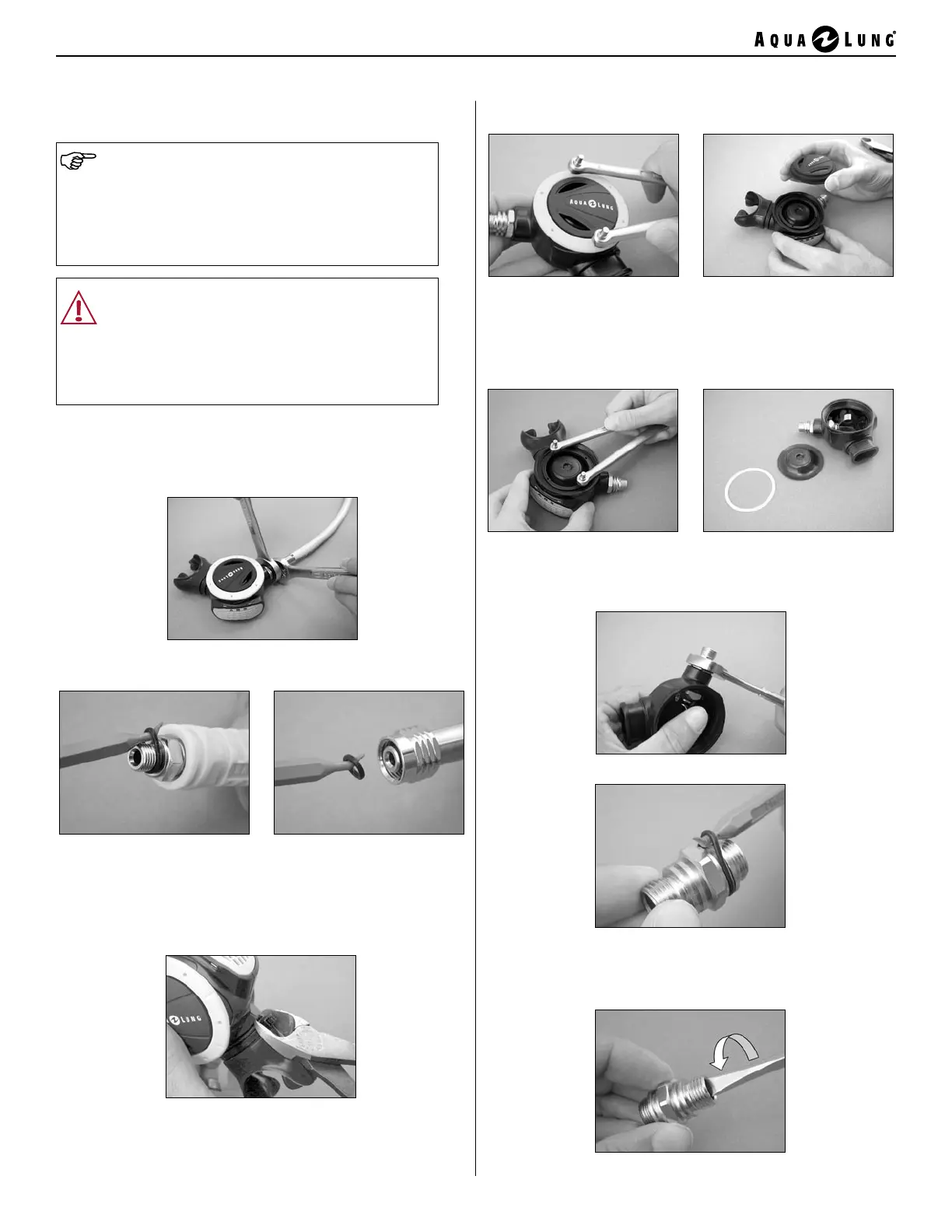

1. While holding the inlet fitting (12) of the second stage

secure with a ¾" (19mm) open end wrench, apply 11/16"

(17mm) open-end wrench to the female fitting of the LP hose

(26). Turn the fitting counter-clockwise to remove the hose

from the second stage.

2. Remove the o-rings (24&27) from the hose and discard.

Set the hose aside.

3. Using sidecutters, carefully snip the plastic mouthpiece

clamp (23) and remove the mouthpiece (22) from the box bot-

tom (19). Inspect the mouthpiece to ensure it is free of any

tears or cuts that may cause leakage of water into the second

stage or other discomfort. Discard the mouthpiece or set it

aside to be reused, depending on its condition.

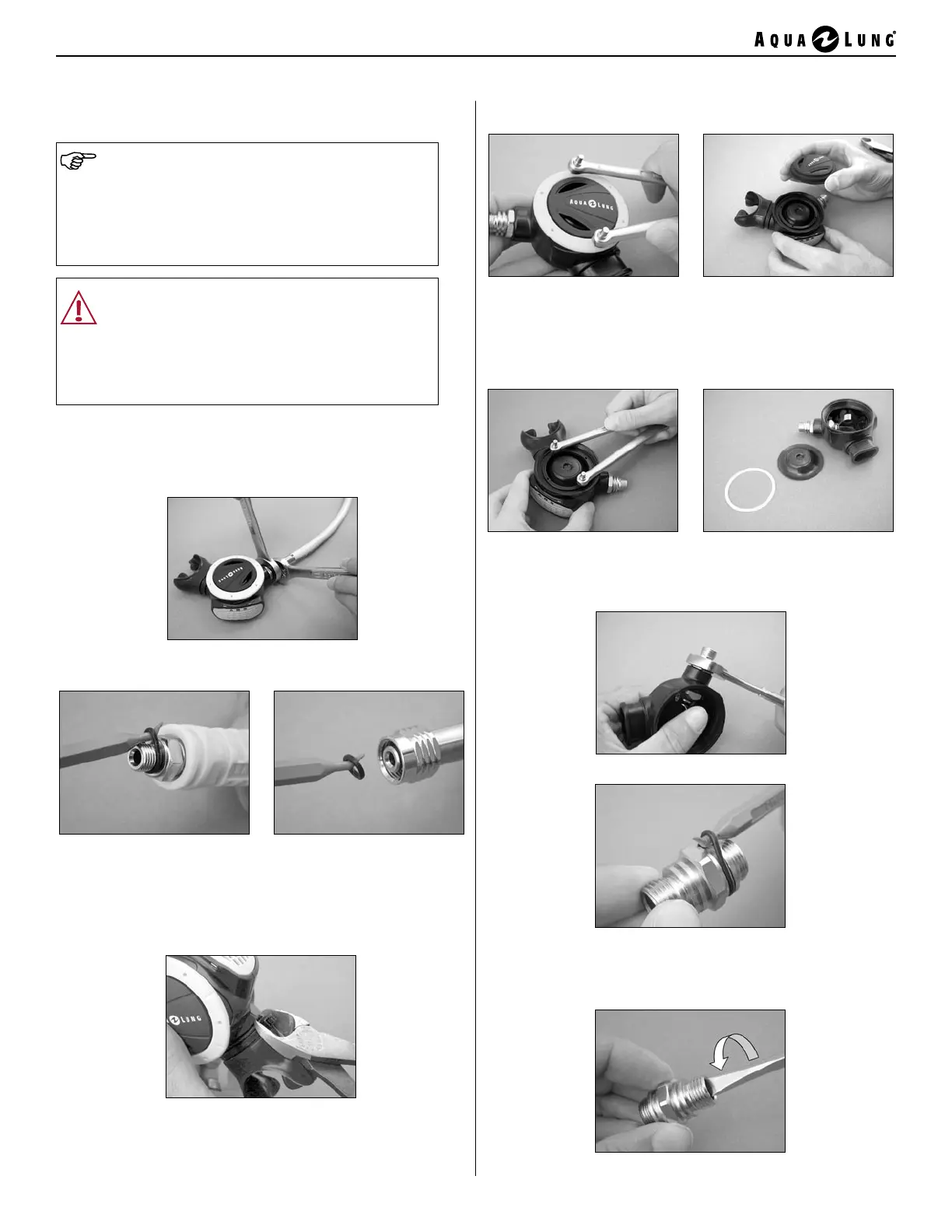

5. Using the adjustable spanner wrench (p/n 129198),

remove the diaphragm retainer (16). Remove washer (17)

and diaphragm (18). Inspect the diaphragm for any signs

of tears, deterioration, or other damage. If deterioration or

damage is found, discard the diaphragm and do not attempt

to reuse.

6. While holding the box bottom (19) secure, apply a 3/4”

open end wrench to the inlet fitting (12). Hold the lever (3)

depressed, and carefully turn the fitting counter-clockwise to

loosen and remove.

7. Remove and discard the o-ring (11).

8. Apply a medium blade screwdriver to the slotted head of

the crown (21) inside the inlet fitting (12), and hold the inlet

fitting secure while turning the crown counter-clockwise to

disengage the threads.

DISASSEMBLY PROCEDURES

NOTE: Before performing any disassembly, refer

to the exploded parts drawing, which references all

mandatory replacement parts. These parts should

be replaced with new, and must not be reused

under any circumstances – regardless of the age

of the regulator or how much use it has received

since it was last serviced.

CAUTION: Use only a plastic or brass o-ring

removal tool (p/n 944022) when removing o-rings

to prevent damage to the sealing surface. Even

a small scratch across an o-ring sealing surface

could result in leakage. Once an o-ring sealing

surface has been damaged, the part must be

replaced with new. DO NOT use a dental pick,

or any other steel instrument.

4. Using the adjustable spanner wrench (p/n 129198), re-

move the retaining ring (14). Remove the purge cover (15).

Loading...

Loading...