FOR MODELS: JGI, JGM, JGN, JGP AND JGQ SECTION 1 - DESIGN SPECIFICATIONS & DATA

9/08 PAGE 1-17

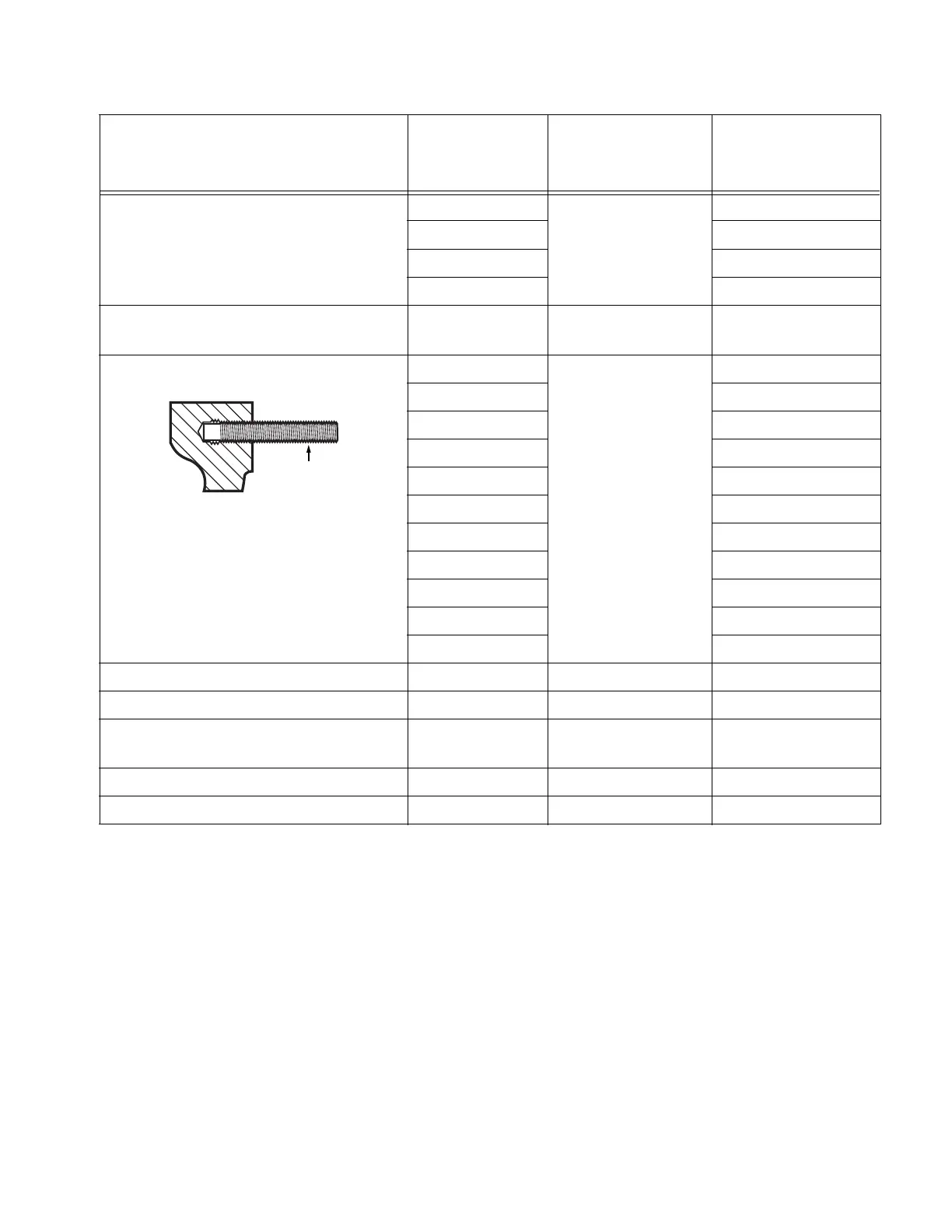

Tandem Cylinder to Cylinder - Cap

Screw

c

1/2 - 13 Hex - Grade 8 or 9

or

12 Point - Grade 8

44 (60)

5/8 - 11 88 (120)

3/4 - 10 160 (215)

3/4 - 16 180 (245)

Fanshaft to Crankshaft - Central

Stud

3/4 - 16 Ariel Design 250 (340)

Seating Studs in Cylinder 3/8 - 16 Dog Point 107 lb-in. (12)

7/16 - 14 172 lb-in. (19)

1/2 - 13 22 (30)

9/16 - 12 32 (43)

5/8 - 11 44 (60)

5/8 - 18 51 (70)

3/4 - 10 79 (105)

3/4 - 16 90 (120)

7/8 - 9 130 (170)

7/8 - 14 145 (195)

1 & Larger 200 (270)

Spacer Bar 5/8 -11 Cap Screw Gr. 8 92 (125)

Distribution Block Tie Rod - Nut 1/4 - 28 Hex 68 lb-in. (7.7)

Distribution Block Divider Valve -

Screw

1/4 - 28 Socket Head 75 lb-in. (8.5)

Force Feed Lubricator 1 - 14 Hex Jam Nut 75 (100)

Grade 5 - Hex Cap Screw All Hex - Grade 5 Hand-wrench Tight

a. Tighten, loosen, and re-tighten the Piston Nut to ensure proper tightening.

b. Use the Ariel Tried and True Slugging Method, see Section 5.

c. Minimum torque for recommended, 5/8” - 11TPI for JGM, JGN, JGP, JGQ and 3/4”-10TPI for JGI, hold

down stud size to provide stress in stud of 55,000 psi (380 MPa). Stud must have an ultimate strength

of 100,000 psi (690 MPa) or greater. If greater, increase torque to stress stud to about 55% of ultimate

strength of stud material, as specified by packager.

TABLE 1-12 FASTENER TIGHTENING VALUES

FASTENER

NOMINAL

SIZE,

INCH - TPI

TYPE

TORQUE,

LB-FT (N·m)

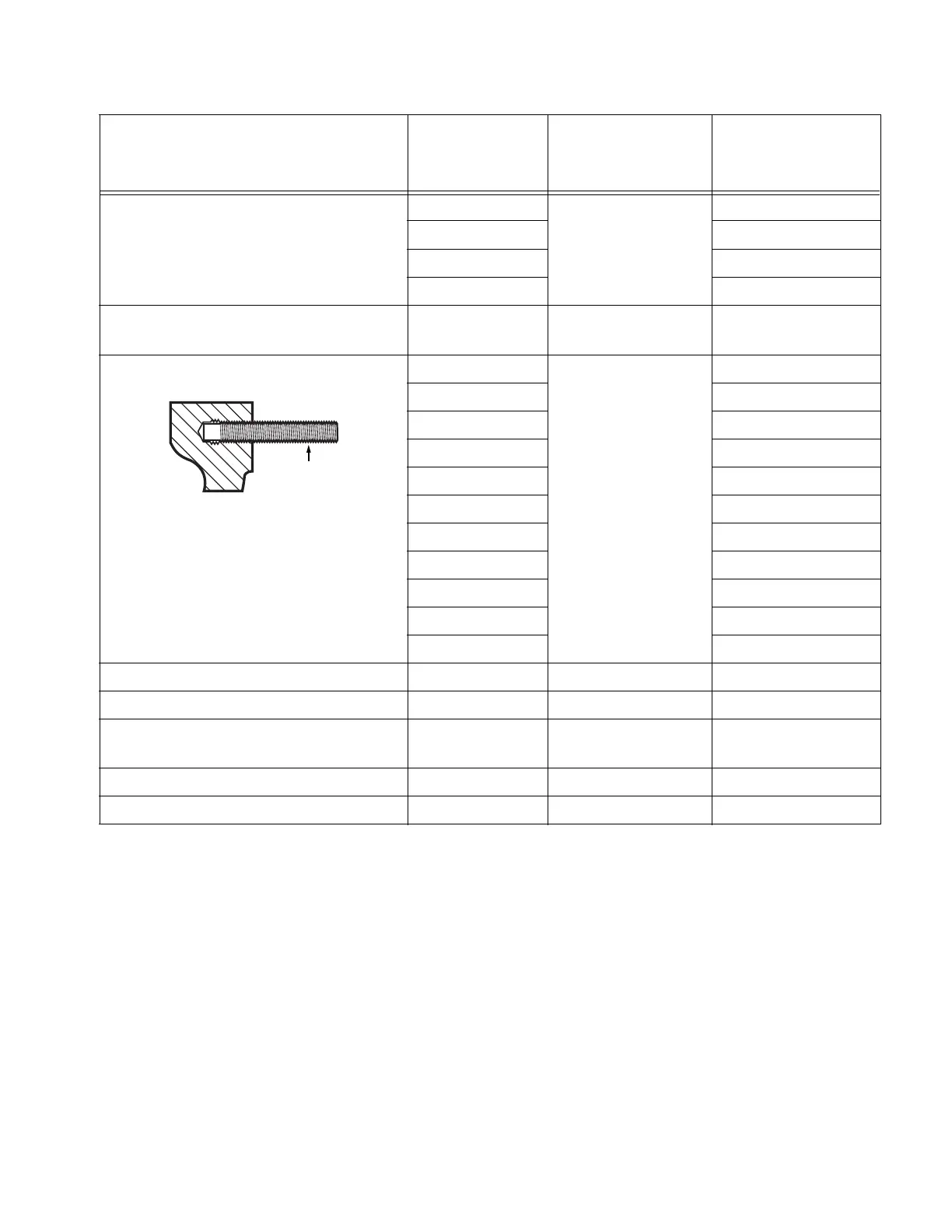

Dog Point

Stud

Loading...

Loading...