FOR MODELS: JGI, JGM, JGN, JGP AND JGQ SECTION 4 LUBRICATION

PAGE 4-18 9/08

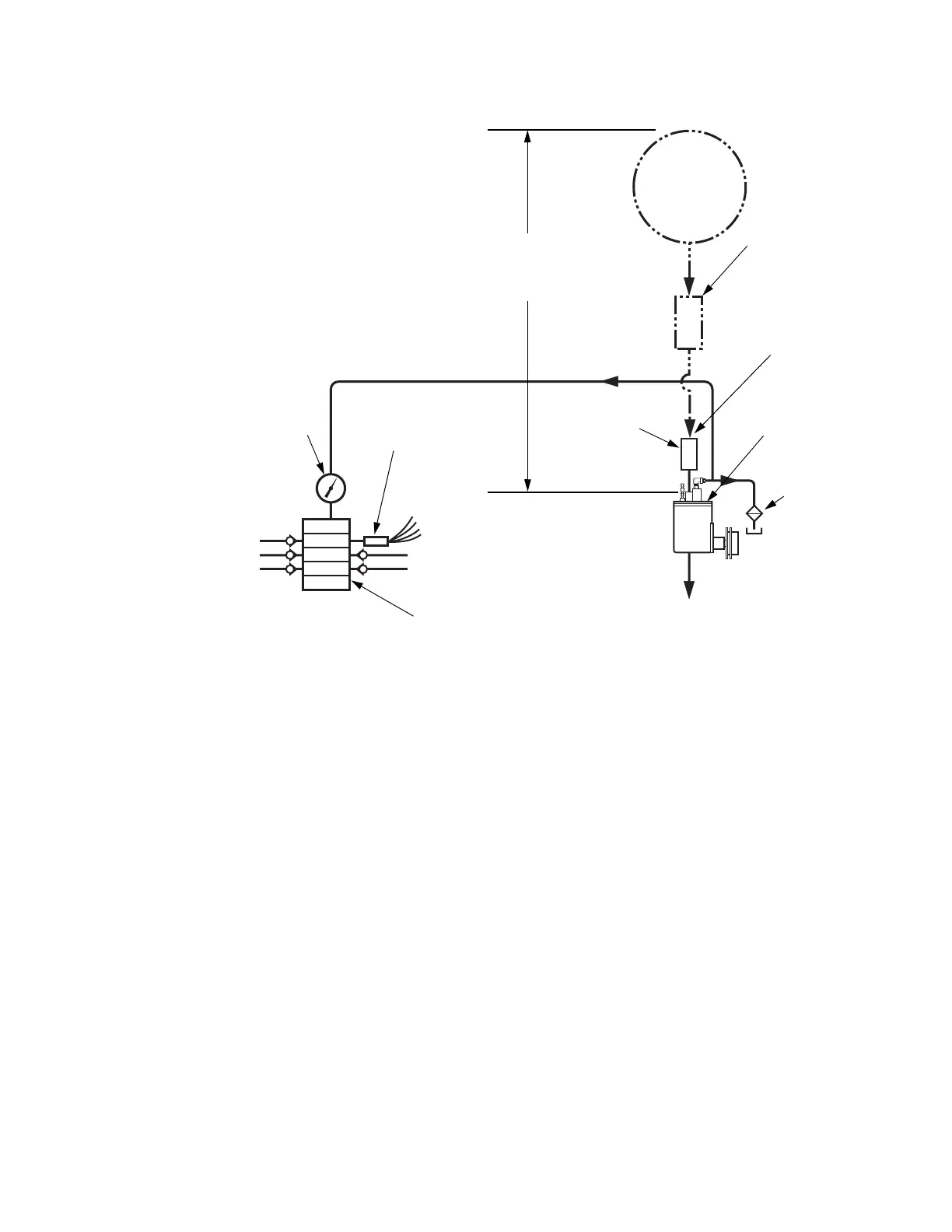

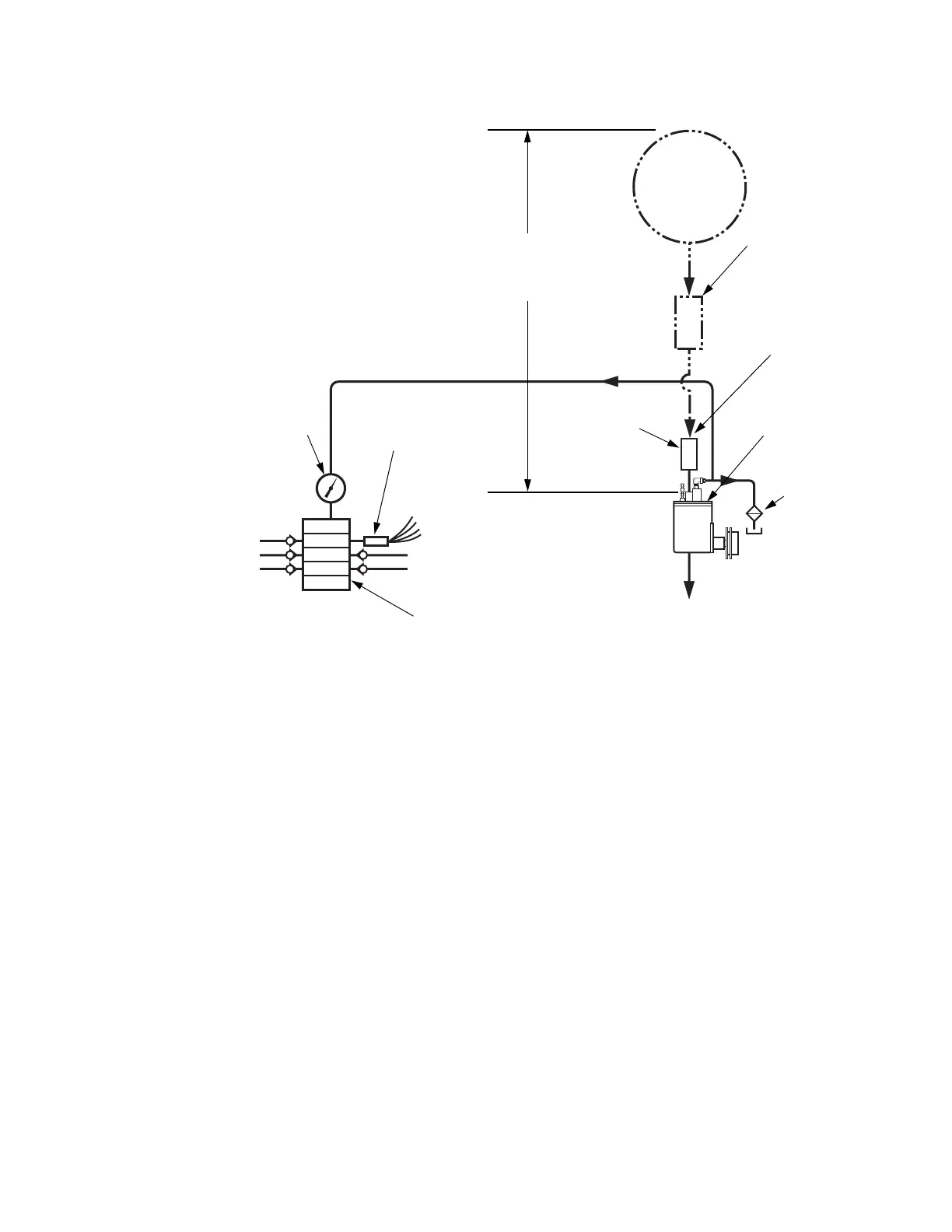

Independent Oil Supply

NOTE: System must pro-

vide positive pressure to

force feed lubricator

pump.

Pump Suction

1/4 inch NFT

(Female)

Customer

Connection

Divider Valves -

Distribution Block

Fluid Flow Moni-

tor No-Flow Timer

Shutdown Switch

To Appropriate Drain 1/4 inch NPT

(Female) Customer Connection

Do Not Drain to Crankcase

Blow-Ou

Disc

Force Feed

Lubicator

Pump

Oil Filter

Sintered

Bronze

Filter

Pressure

Gauge

FIGURE 4-6 FORCE FEED LUBRICATION SYSTEM - INDEPENDENT OIL

SUPPLY

Oil Supply

Tank

When process gas

composition and

cylinder operating

conditions require

an independent cyl-

inder and packing

oil supply, the

resulting separate

force feed lube sys-

tems require an oil

supply. Lubricator

oil is supplied

under pressure

from an elevated

tank. To prevent the

compressor frame

oil from being con-

taminated by the

force feed oil, be

sure that the lubri-

cator box over flow

does not drain into

the crankcase. The

lubricator box over

flow tubing must be

disconnected from

the compressor

frame and directed

to an appropriate drain system.

Independent force feed lube systems require oil with a viscosity below 5000 SUS (1

100 cSt)

at the lubricator pump inlet. Measures which may be necessary to make sure that the force

feed pump is filled with oil during the suction stroke include; appropriate pipe and fitting size

from the tank to the force feed pump, heating the oil, and pressurizing the supply tank. An in-

line oil filter or fine screen is required between the supply tank and the force feed lubricator

pumps. Recommended filtration is 5 micron nominal.

Force Feed Lubrication System Components

Gas Inlet Debris Screens to Maintain Lube Performance

Even when the proper rate and lubricating medium are in use, dirt and foreign matter in the

gas will prevent the lubricant from performing properly. Prior to start-up, cone type inlet gas

debris strainers with 100 mesh per inch (150 micron) screen and perforated metallic backing

are to be installed in a pipe spool between the inlet scrubber and cylinder suction flange. In

Loading...

Loading...