60 /

BOILER PROTECTION DEVICES

Appliance shut-off conditions

The boiler is protected from malfunctions by means of internal

checks performed by the electronic P.C.B., which stops the boiler

from operating if necessary. In the event of the boiler being shut

off in this manner, a code appears on the control panel display

which refers to the type of shut-off and the reason behind it.

Two types of shut-off may occur:

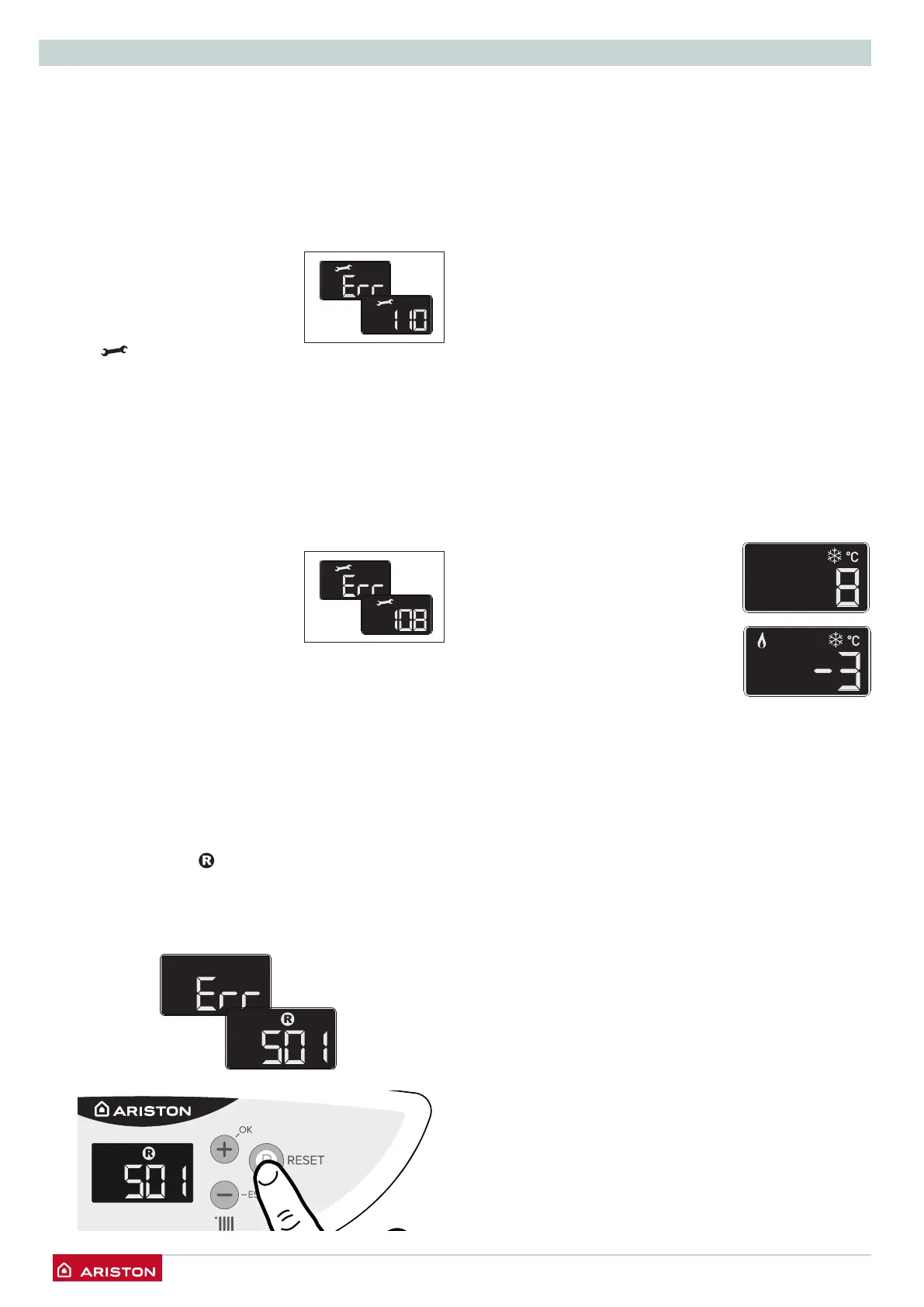

Safety shut-off

This type of error is “volatile”, which

means that the boiler starts up again

automatically as soon as the problem

which caused the shut-off is removed.

On the display ash “Err” and the error

code (es. Err/110) and appear the

symbol - see the error table.

In fact, soon as the cause of the shut-off disappears, the boiler

starts up again and continues to operate normally.

While the boiler is shut off for safety reasons, it is possible to

attempt to restore normal operation by switching the appliance

off and on again using the ON/OFF button on the control panel.

If the boiler still indicates a safety shut-off, switch it off. Make

sure the external electric switch is in the OFF position, shut off

the gas valve and contact a qualied technician.

Safety shut-off due to insufcient water pressure

If the water pressure inside the heating

circuit is insufcient, the boiler will

perform a safety shut-off. On the display

ash “Err” and the code - Err/108 -

for Insufcient water pressure -- see

the error table.

Check the water pressure on the

pressure gauge and make sure that is

between 0.6 and1.5 bar when the system is cold. If the pressure

is just under the minimum rell the system by open the valve

under the boiler.

If the pressure drops very frequently, there may be a water leak

at some point in the system. If this is the case a plumber should

be contacted.

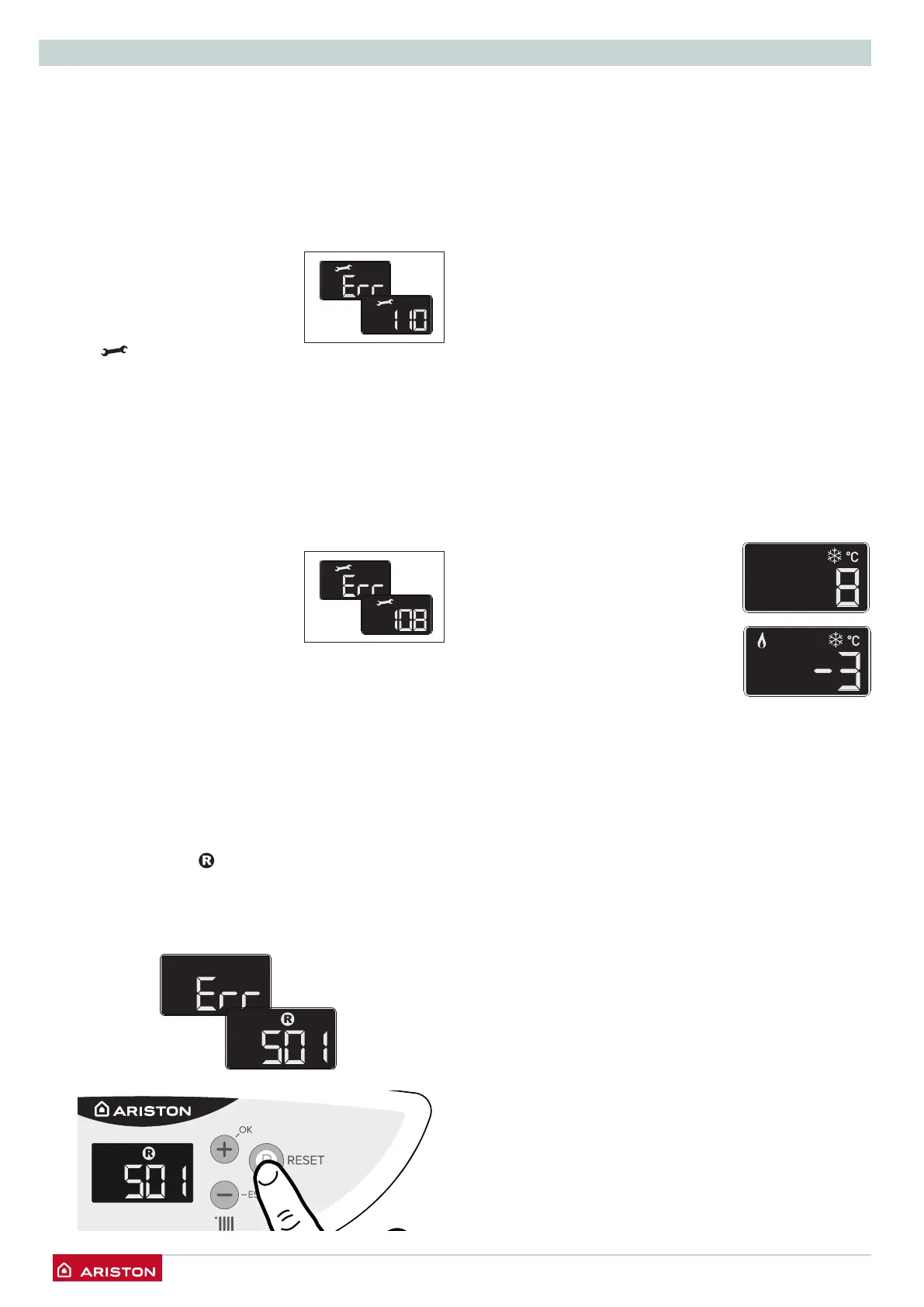

Operation shutdown

This type of error is “non-volatile”, which means that it is not

removed automatically.

On the display ash Err and the error code -es. Err/501 ,

and appear the symbol .

In this case the boiler does not restart automatically, but it may

be reset by pressing the RESET button. If the problem manifests

itself again after several attempts to reset the appliance, contact

a qualied technician.

Important

If this shutdown occurs frequently, contact an authorised service centre

for assistance. For safety reasons, the boiler will allow a maximum of 5

reset operations to take place in 15 minutes (individual presses of the

RESET button).

If the shutdown is occasional or an isolated event, this is not necessarily

a problem.

The rst gure of the error code (e.g. 1 01) indicates within

which operational assembly the error occurred.

1 - Primary Circuit

2 - Domestic Hot Water Circuit

3 - Internal Electronic Part

4 - External Electronic Part

5 - Ignition and Detection

6 - Air inlet - ue gas outlet

Malfunction warning

This warning is shown by the display in the following format:

5 P35 P3 = Flame cut-off

the rst gure indicating the operational assembly is followed

by a P (warning) and the code relating to the specic warning.

Anti-frost Device.

The anti-frost function acts on the central heating ow temperatu-

re probe, independently from other regulations, when the electrical

supply is turned on.

If the primary circuit temperature falls be-

low 8°C the pump will run for 2 minutes.

After the two minutes of circulation (xed)

the boiler will check the following:

a) if the central heating ow temperature

is > 8°C, the pump stops;

b) if the central heating ow temperature

is between 4 and 8°C, the pump will

run for another two minutes;

c)

if the central heating ow temperature is

< 4°C, the burner will re (heating posi-

tion) at minimum power until the tempe-

rature reaches 33°C, the burner will go

out and the pump will continue to run for two minutes.

If the ow temperature remains between 4-8°C the pump will

continue to run for two minutes for a maximum of 10 times

unless a temperature above 8°C is detected in the central hea-

ting ow, after this the the burner will re. If lockout is caused by

overheat the burner is kept OFF.

The anti-frost device activates only when (with the boiler opera-

ting correctly):

- the system pressure is correct;

- the boiler is electrically powered;

- there is a supply of gas.

Loading...

Loading...